Special tool for tightening live side bolts by ground potential method

A special tool and ground potential technology, which is applied in the direction of manufacturing tools, hand-held tools, overhead line/cable equipment, etc., can solve the problems of large swing range of insulators and their connecting fittings, easy loosening of bolts of connecting fittings, and great difficulty. Achieve the effects of wide range of fastening angle specifications, long-term stable use, reliable and durable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

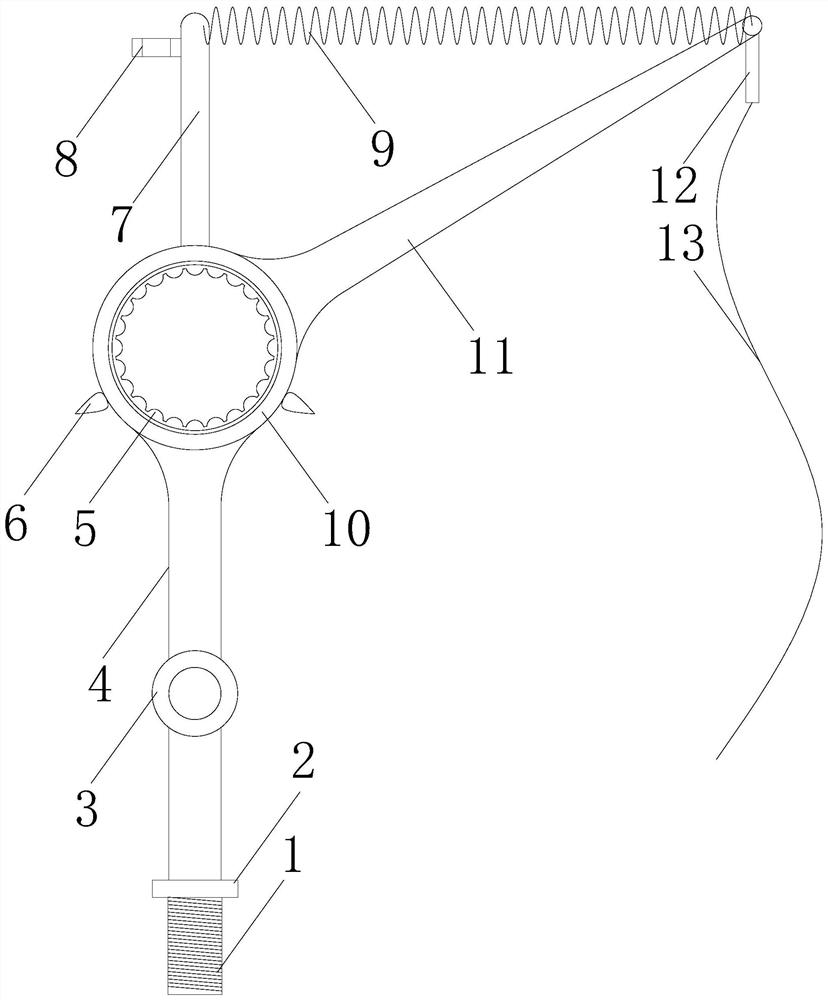

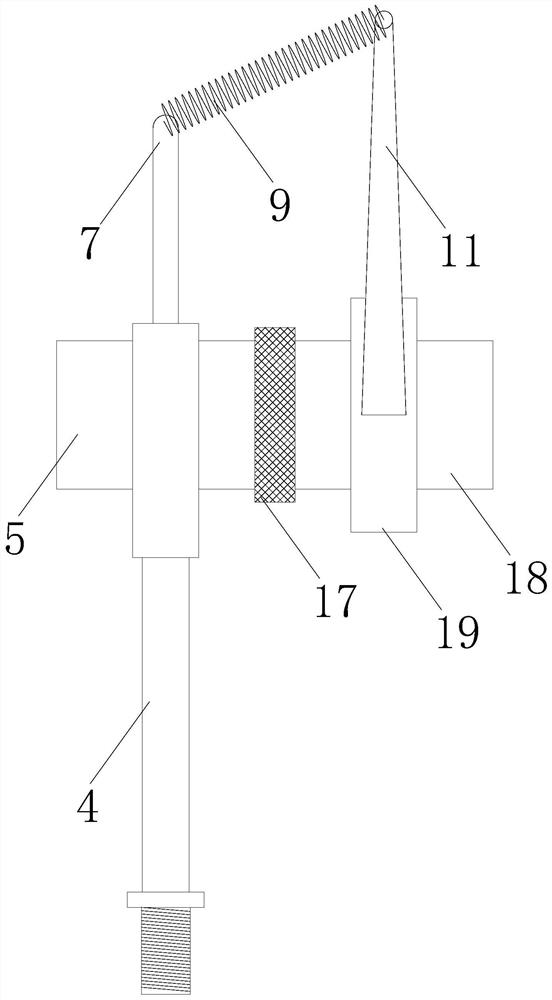

[0043] like Figures 1 to 10 shown, which illustrate specific embodiments of the invention, such as Figure 1-10 As shown in the figure, the special tool for tightening the live side bolts by the ground potential method disclosed in the present invention includes an operating rod, the operating rod is connected to the fixed arm 4, and the fixed arm assembly head 10 of the fixed arm 4 is connected to the tension arm assembly head of the tension arm 11. A reset arm 7 is extended from the top of the fixed arm 4, and a reset tension spring 9 is connected between the distal end of the tension arm 11 and the reset arm 7;

[0044] The distal end of the tension arm 11 is also provided with a pull rope loop 12, and the pull rope loop 12 is connected with a pull rope 13;

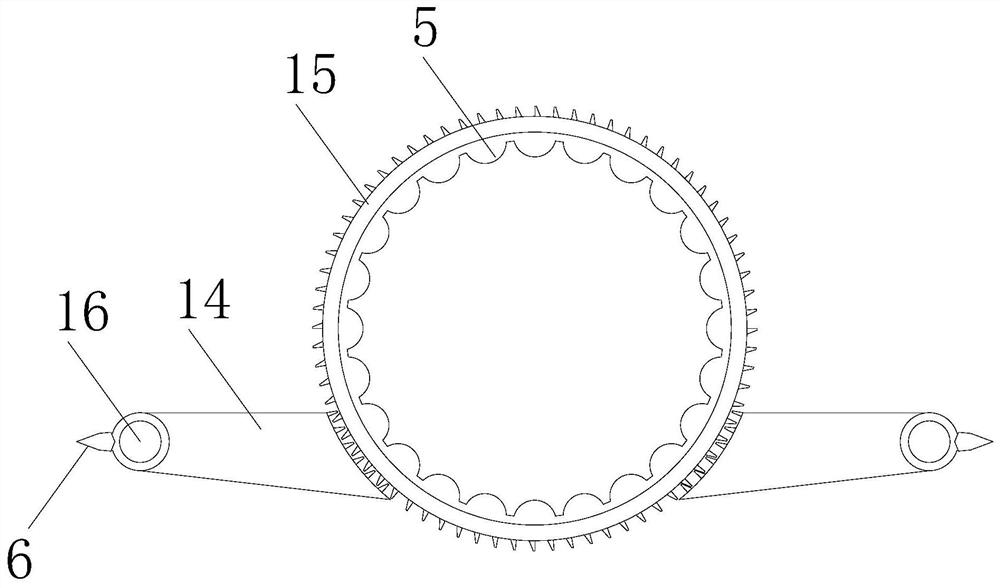

[0045] The fixed arm ratchet rotating sleeve 5 is rotatably installed on the fixed arm assembling head 10, the inner wall of the fixed arm ratchet rotating sleeve 5 is a polygonal structure for assembling bolts, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com