Soil-piling flower box and greening structure adopting same

A soil flower box and soil piling technology, applied in the greening field, can solve the problems of affecting the greening area and greening effect, single planting surface, and high maintenance cost, so as to improve the survival rate and growth effect, improve the greening area, and have good water absorption and water retention. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

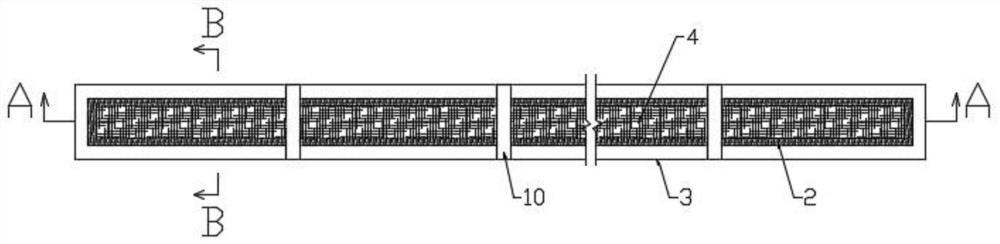

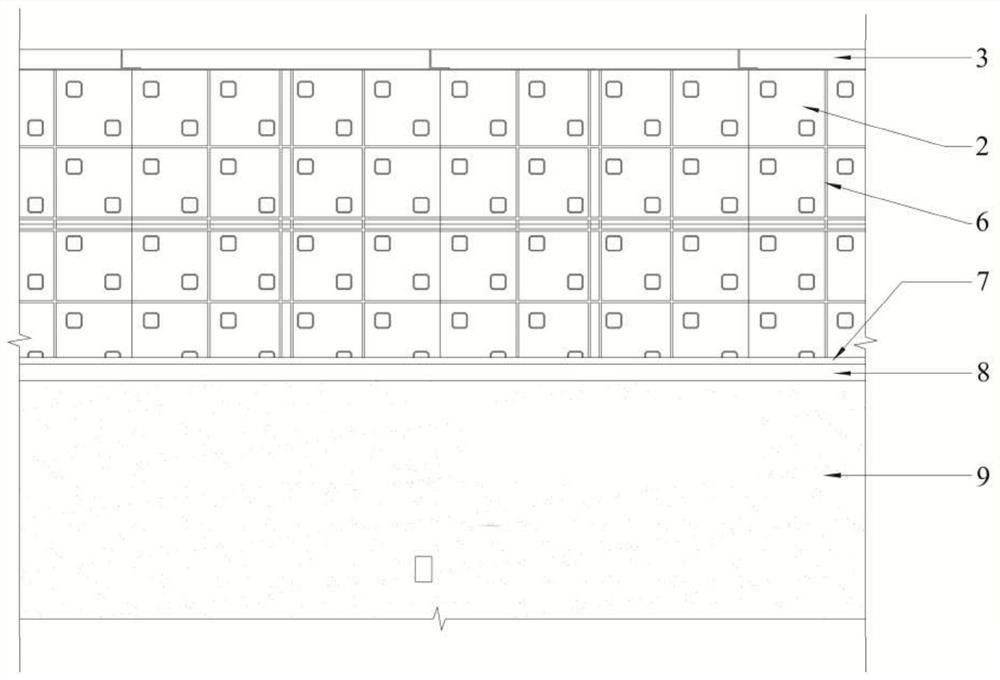

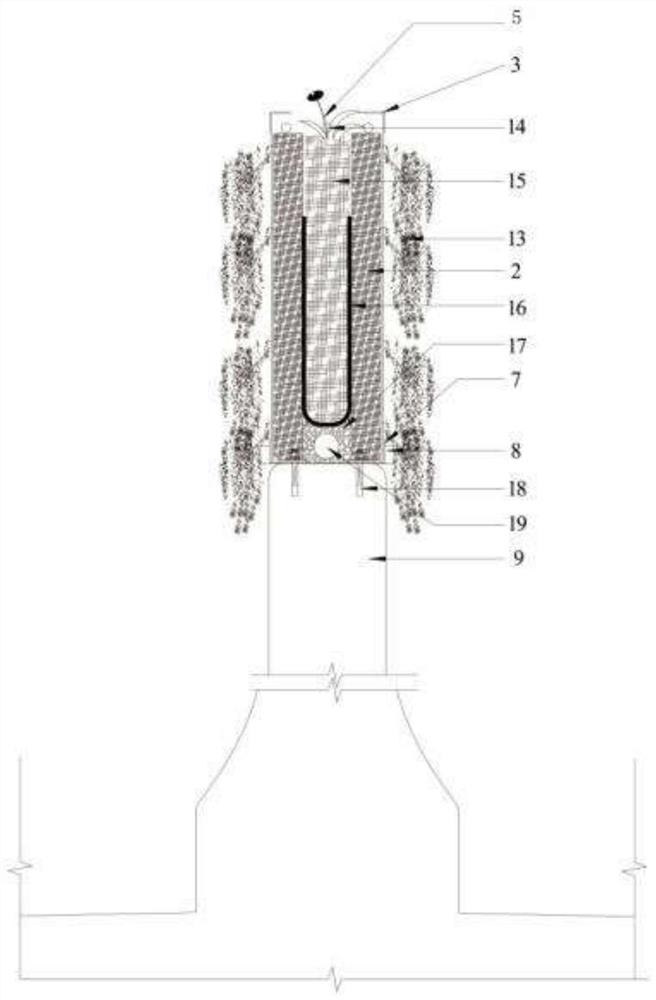

[0029] The present invention will be described in detail below in conjunction with accompanying drawing, as Figure 1-6 Shown: This embodiment provides a kind of soil-building flower box, including a box body and a water tank 8 arranged at the bottom of the box body, the box body includes a keel frame, a soil layer 2 fixed on the inside of the keel frame, and The base soil grid frame 6 between the framework and the base soil layer. The keel frame includes a top angle steel 3, a cross angle steel 10, a bottom angle steel 7 and a vertical angle steel 11. The cross angle steel 10 spans between the top angle steel 3 welded on both sides, and the bottom angle steel 7 and the water tank 8 Welding, the vertical angle steel 11 is welded between the top angle steel 3 and the bottom angle steel 7 on the same side, and a reinforcing steel plate 12 is welded between the vertical angle steels on both sides.

[0030] The soil layer 2 encloses a filling cavity 4 , and the filling cavity is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com