Treatment method for improving expanded cut tobacco quality

A technology for expanding shredded tobacco and a processing method, which is applied in the field of cigarette manufacturing, can solve the problems of poor addition effect, increased cost, and insufficient coordination of chemical components of tobacco powder, and achieves the effects of low cost, reduced content of macromolecular substances, and coordination of chemical components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

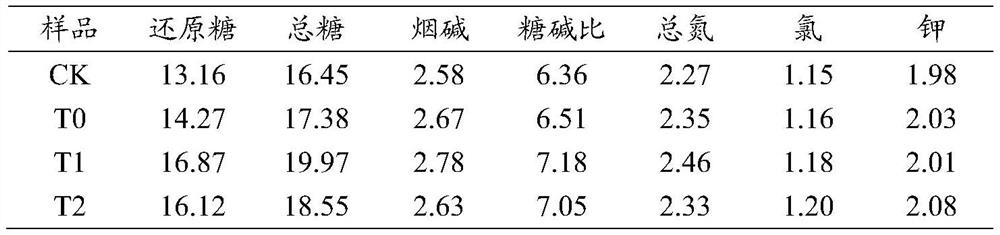

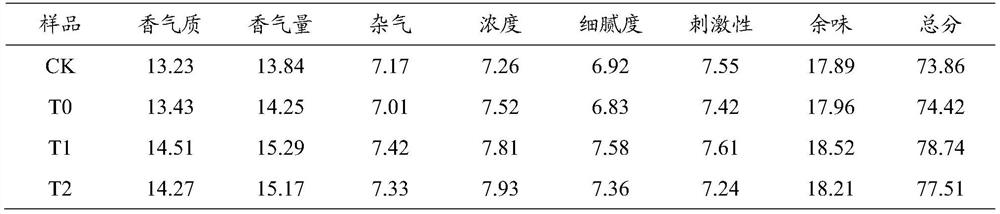

Examples

Embodiment 1

[0066] 1. Pass the exiting tobacco powder (from the packaging workshop of China Tobacco Gold Leaf Manufacturing Center in Henan Province) through a 100-mesh sieve, take out the small particle size exiting tobacco powder, add deionized water according to the mass ratio of material to liquid 1:12, and store at 70°C Heat and extract at constant temperature for 1 hour, filter and sterilize at 121° C. for 15 minutes with high temperature and damp heat to obtain smoke powder extract.

[0067] 2. Using Brettanomyces isolated from distiller's yeast as a fermentation strain, a single colony was picked from the slope and inoculated into 50 mL of tobacco powder extract, and incubated for 24 hours with constant temperature and vibration to obtain tobacco powder seed liquid.

[0068] 3. According to the volume ratio of 1:50, inoculate the tobacco powder seed solution into a fermenter containing 3L of tobacco powder extract, and incubate at a constant temperature with vibration for 48 hours ...

Embodiment 2

[0074] 1. Pass the exiting tobacco powder (from the packaging workshop of China Tobacco Gold Leaf Manufacturing Center in Henan Province) through a 100-mesh sieve, take out the small particle size exiting tobacco powder, add deionized water according to the mass ratio of material to liquid 1:12, and store at 70°C Heat and extract at constant temperature for 1 hour, filter and sterilize at 121° C. for 15 minutes with high temperature and damp heat to obtain smoke powder extract.

[0075] 2. Using Bacillus subtilis capable of degrading proteins as a fermentation strain, pick a single colony from the slope and inoculate it into 50 mL of tobacco powder extract, and culture it with constant temperature and vibration for 24 hours to obtain tobacco powder seed liquid.

[0076] 3. According to the volume ratio of 1:50, inoculate the tobacco powder seed solution into a fermenter containing 3L of tobacco powder extract, and incubate at a constant temperature with vibration for 48 hours t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com