Wheat grinding device for food processing

A food processing and grinding device technology, which is applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of affecting work efficiency, reducing the stability of the grinding device, and affecting the filtration efficiency, and achieves structural optimization, convenient re-grinding, and energy saving. saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

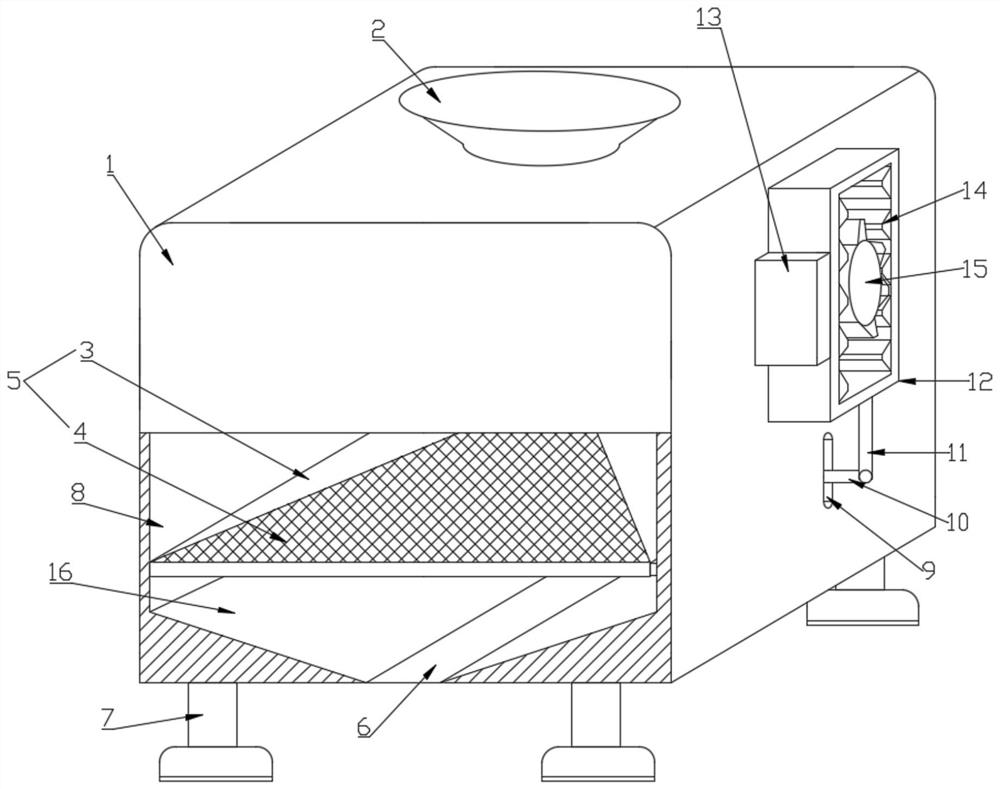

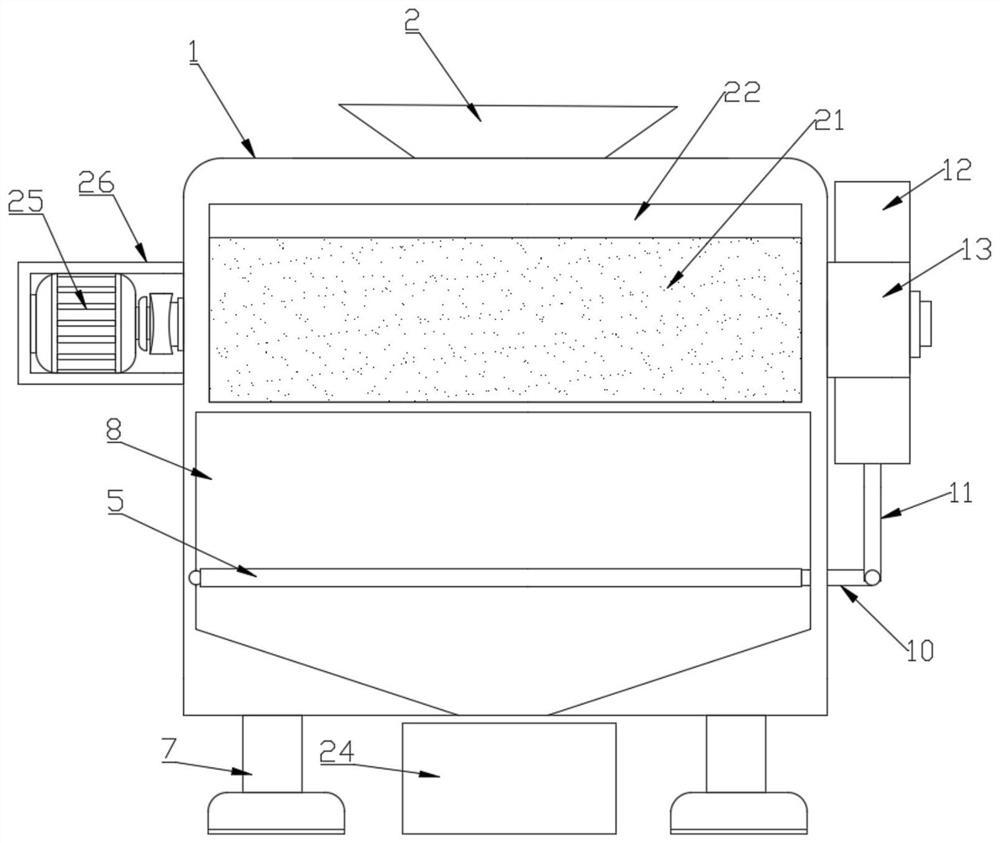

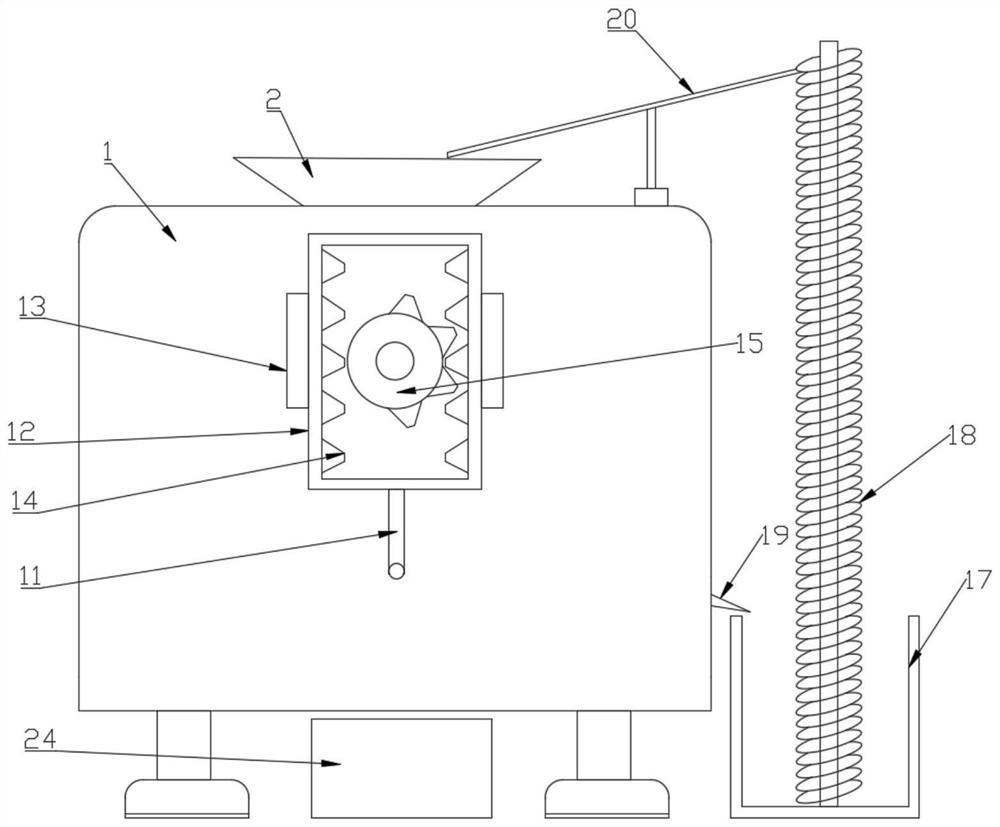

[0027] see Figure 1-5 , the present embodiment provides a wheat grinding device for food processing, including a device body 1 and a support foot 7 fixedly installed at the bottom of the device body 1, the device body 1 is equipped with a feed port 2 and a discharge port 6, A grinding mechanism acting on wheat grains and a screening mechanism acting on wheat flour are also installed on the device body 1;

[0028] The grinding mechanism includes a grinder 21 and a motor 25 fixedly installed on the device body 1, the grinder 21 is rotatably installed in the grinding groove 22 provided on the device body 1 and the grinder 21 is a cylindrical structure, and the grinder 21 is a cylindrical structure. The upper end of the grinding tank 22 communicates with the feeding port 2, the lower half of the grinder 21 is attached to the grinding tank 22, and the upper half of the grinder 21 and the grinding tank 22 have a gap, and the size of the gap gradually decreases from top to bottom ,...

Embodiment 2

[0041] Because the filter screen 4 has an included angle with respect to the horizontal plane, it may cause a large amount of ground wheat flour to fall on the receiving rack 19 before filtering. In order to avoid this situation, the present embodiment is further improved on the basis of embodiment 1. The improvement is: the angle between the filter screen 4 and the horizontal plane is less than 7 degrees, so that the size of the angle between the filter screen 4 and the horizontal plane is limited to ensure that the wheat flour stays on the filter screen 4. Sufficient enough to avoid that the wheat flour has not been filtered and falls on the material receiving rack 19.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com