Copper pipe welding device

A welding device and copper tube technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment and other directions, can solve the problems of reducing welding production efficiency and complicated copper tube welding process, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

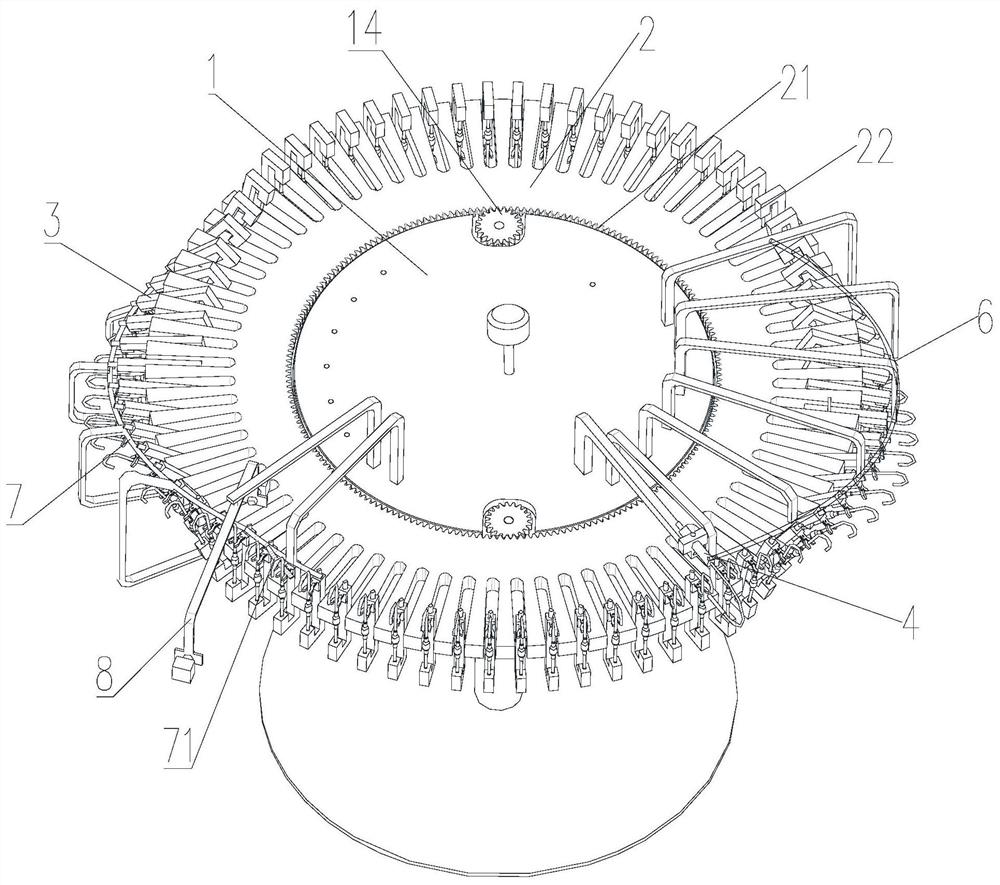

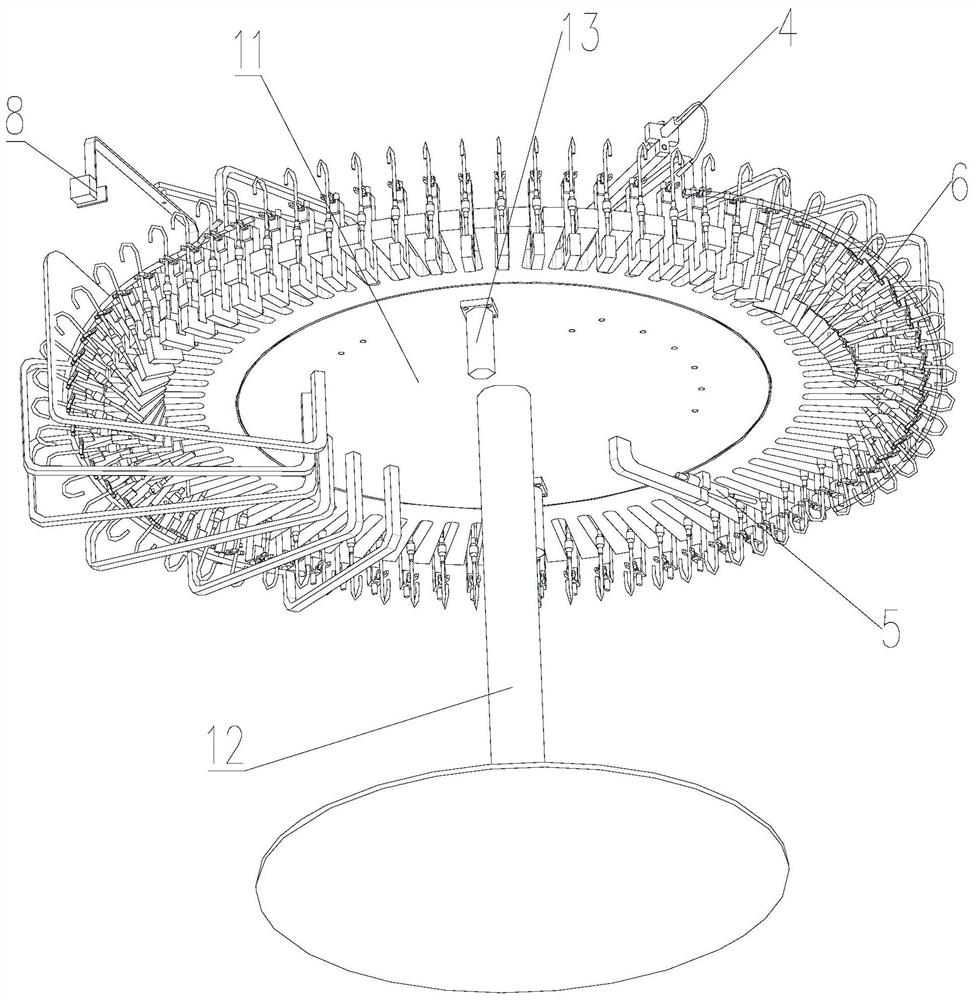

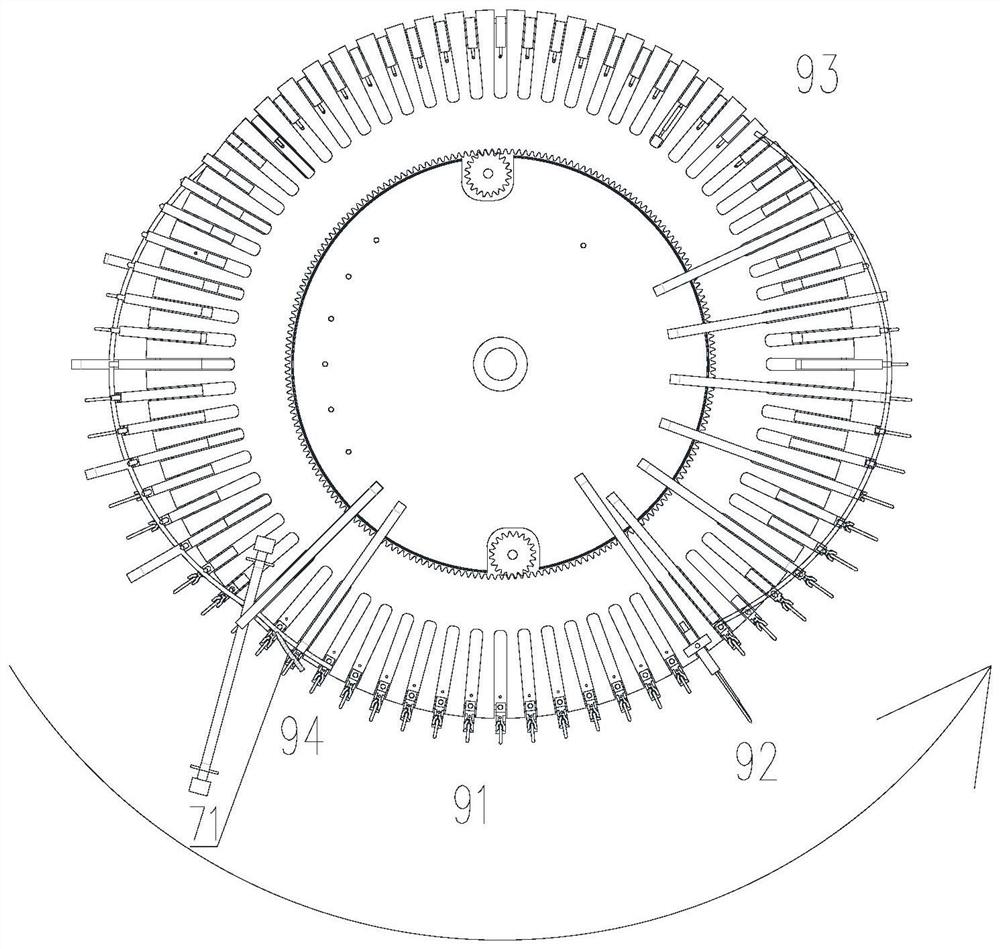

[0026] In order to better understand the purpose, structure and function of the present invention, a copper pipe welding device of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0027] Such as Figure 1-Figure 3 As shown, the present application provides a copper pipe welding device, including a turntable 2, the turntable 2 is arranged on the drive mechanism 1, and the outer circumference of the turntable 2 is provided with a plurality of fixtures 3 for fixing copper pipes. Welding reversing guide rail 6, welding mechanisms are respectively arranged at both ends of welding reversing guide rail 6, driving mechanism 1 drives turntable 2 to rotate, fixture tooling 3 moves along welding reversing guide rail 6, and fixture tooling 3 is turned over 180°, and the places to be welded of copper pipes are respectively connected with The two welding mechanisms are set opposite to each other, so that the two-by-two assembly...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap