Alignment tool for machining for part with closed angle, and a machining method

A technology of parts processing and tools, applied in the field of CNC machining, can solve the problem that the closed angle cannot be aligned, and achieve the effect of improving product quality, ensuring product quality, and expanding practical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

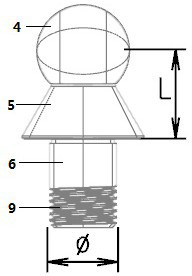

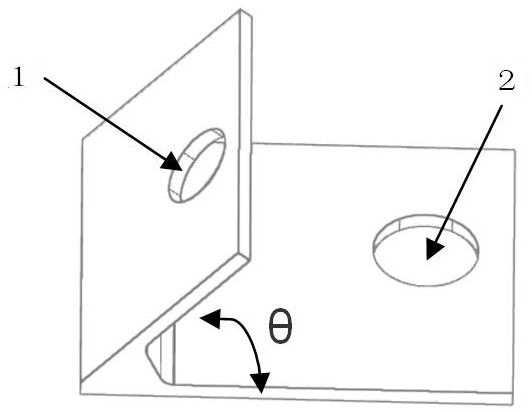

[0045] As a basic embodiment of the present invention, the present invention includes an alignment tool for machining a part with a closed angle. A reference hole 1 is machined on the part, and the alignment tool 3 includes a locking piece and a Spherical alignment piece 4 , conical limiting piece 5 , cylindrical positioning piece 6 . The spherical alignment element 4 is used for alignment center. The other end of the cylindrical positioning member 6 is used to be inserted into the reference hole 1 to cooperate with the locking member to fix the alignment tool 3 . The locking member is a locking nut 7, and the outer wall of the cylindrical positioning member 6 is provided with a thread 9 matching the nut. A plastic ring 8 is provided on the side of the locking nut 7 close to the conical limiting member 5 .

Embodiment 2

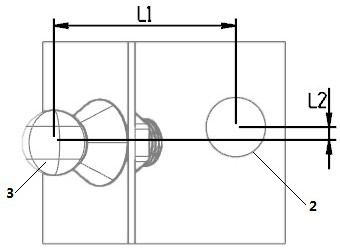

[0047] As a preferred embodiment of the present invention, refer to the accompanying figure 1 , the present invention includes a closed-angle part processing method, which utilizes the alignment tool 3 in the first embodiment. The processing method includes:

[0048] a. Find the reference hole 1 that has been machined in the previous operation on the part.

[0049] b. Determine the outer diameter Φ of the cylindrical positioning member 6 according to the diameter of the reference hole 1, define the distance L between the end face of the conical limiting member 5 away from the spherical alignment member 4 and the center of the spherical alignment member 4, and find the Positive tool 3.

[0050] c. Insert the cylindrical positioning member 6 in the alignment tool 3 into the reference hole 1, and use the cooperation of the locking nut 7 and the thread 9 to lock the part and the alignment tool 3.

[0051] d. Use a feeler gauge to detect the gap between the alignment tool 3 and ...

Embodiment 3

[0056] As the best mode for carrying out the present invention, refer to the appendix of the specification. figure 1 , the present invention includes an alignment tool for machining parts with a closed angle, a reference hole 1 is processed on the part, and the alignment tool 3 includes a locking piece and a spherical alignment piece 4, which are coaxially connected in turn. Conical limiting member 5, cylindrical positioning member 6. The end of the conical limiting member 5 connected with the spherical aligning member 4 is provided with an inwardly concave groove that matches the spherical aligning member 4, so as to facilitate better connection with the spherical aligning member 4 and ensure that the The requirement of coaxiality reduces the cumulative error, and does not affect the position of the contact point of the watch needle when confirming the center of the spherical alignment member 4 .

[0057] The other end of the cylindrical positioning member 6 is used to be in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com