Efficient battery replacing system of electric commercial vehicle

A commercial vehicle and electrical system technology, applied in electric vehicles, electric power devices, charging stations, etc., can solve the problems of difficult realization of electric commercial vehicle charging requirements, impossibility of popularization and application, large capacity differences, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

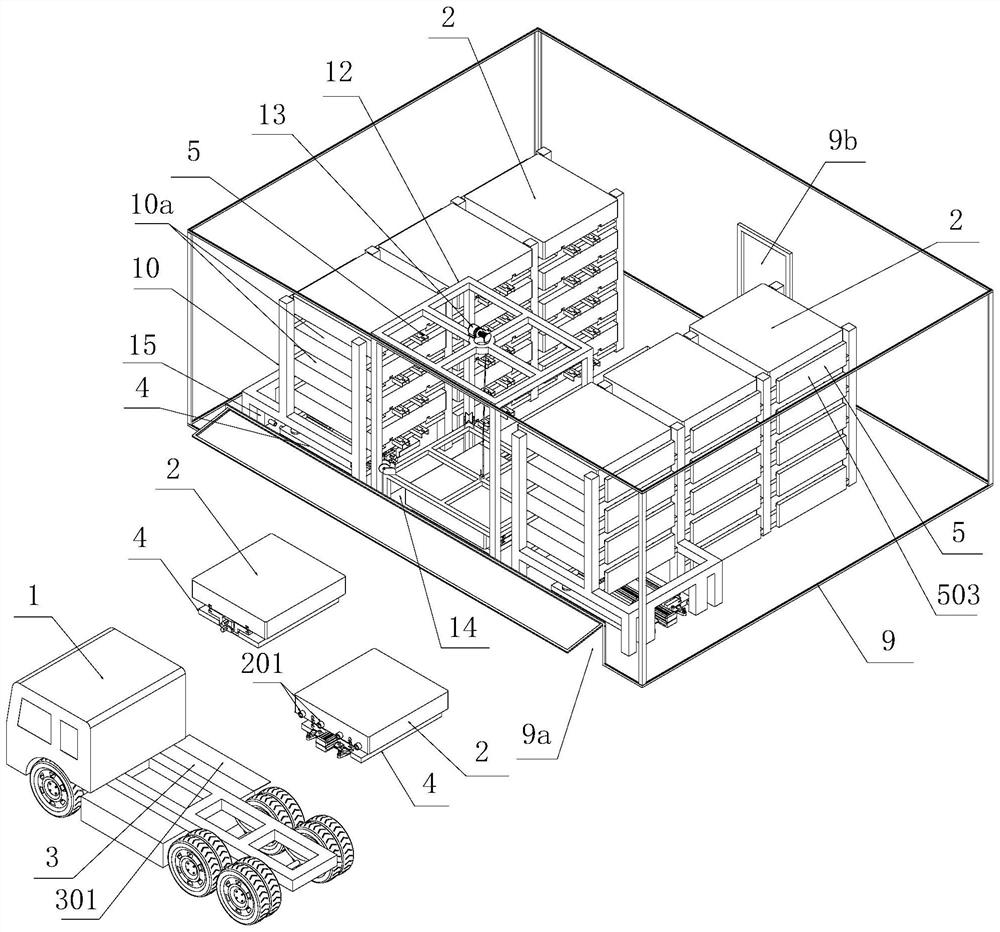

[0079] Embodiment: combine below Figure 1~15 The high-efficiency power exchange system for electric commercial vehicles provided by the present invention is described in detail as follows:

[0080] first as figure 1 As shown, from an overall point of view, the present invention consists of an electric commercial vehicle 1 with a replaceable battery pack 2, a battery compartment 3 for accommodating the battery pack 2 arranged on the electric commercial vehicle 1, and a power exchange station, wherein the power exchange station is composed of a battery exchange trolley 4 Together with the charging house.

[0081] The electric commercial vehicle 1 mentioned in the present invention has not improved its power drive part, and only the battery compartment 3 and its placement form, and the supporting battery pack 2 have been improved.

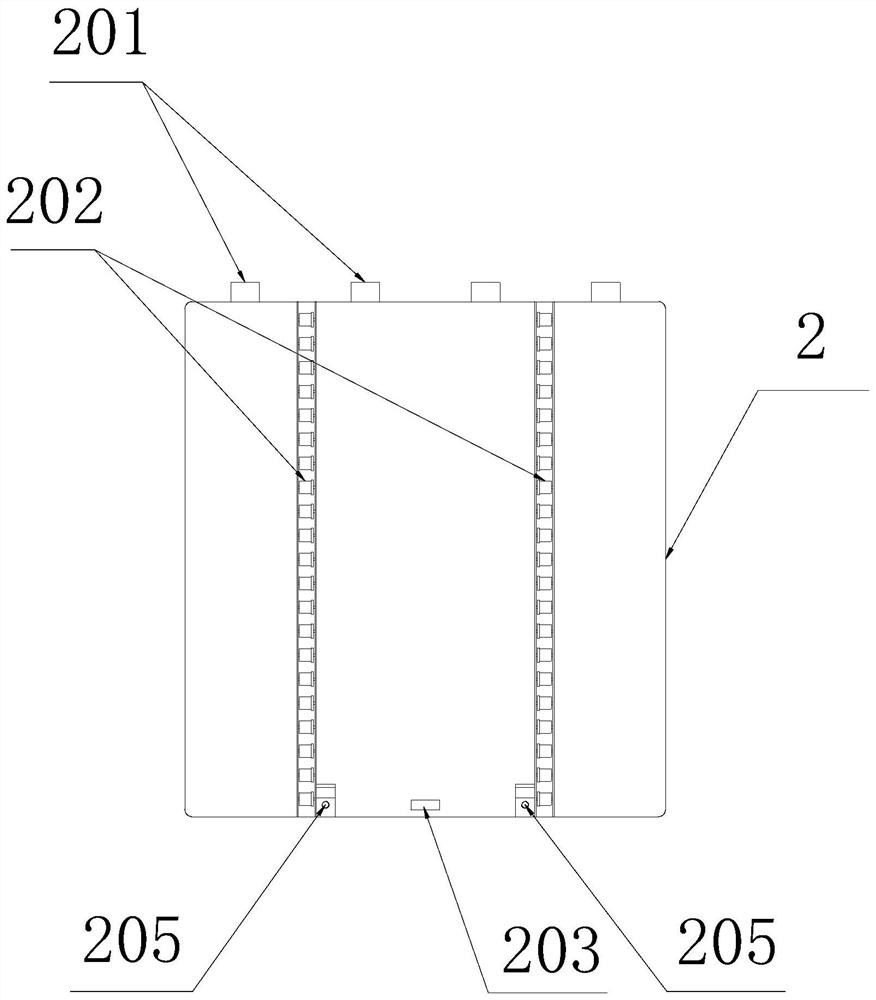

[0082] combine first Figure 2~4 To illustrate the battery pack 2, the battery pack 2 in the present invention is designed in a cuboid shape, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com