On-line automatic tray placing device

An automatic and transfer mechanism technology, which is applied in transportation and packaging, conveyor objects, stacking of objects, etc., can solve the problems of waste, waste and low efficiency in processing costs, and achieve the effect of avoiding collisions and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

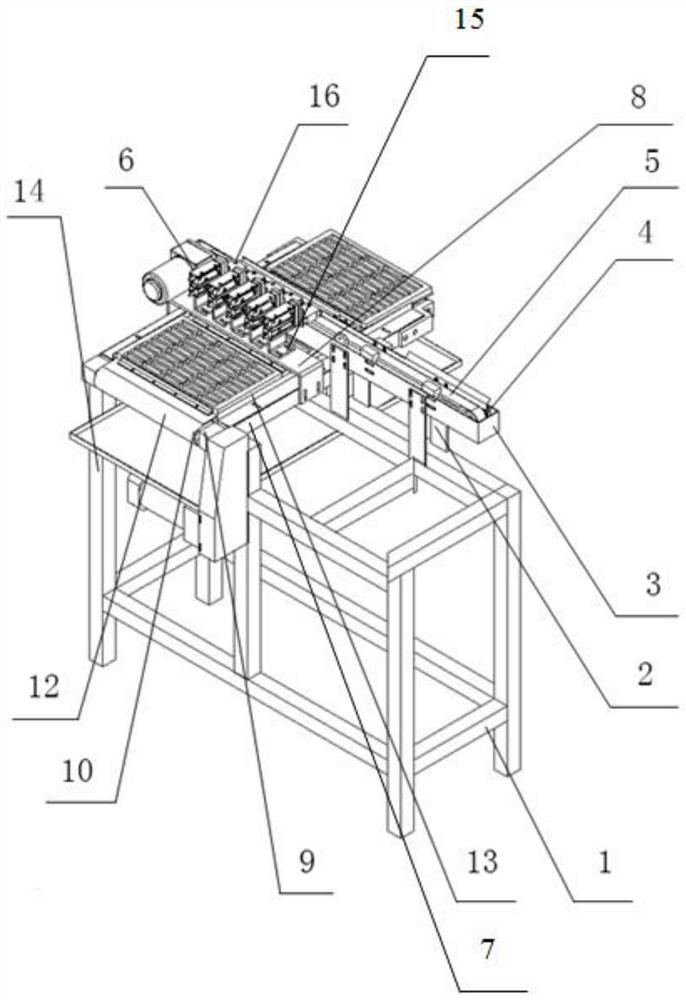

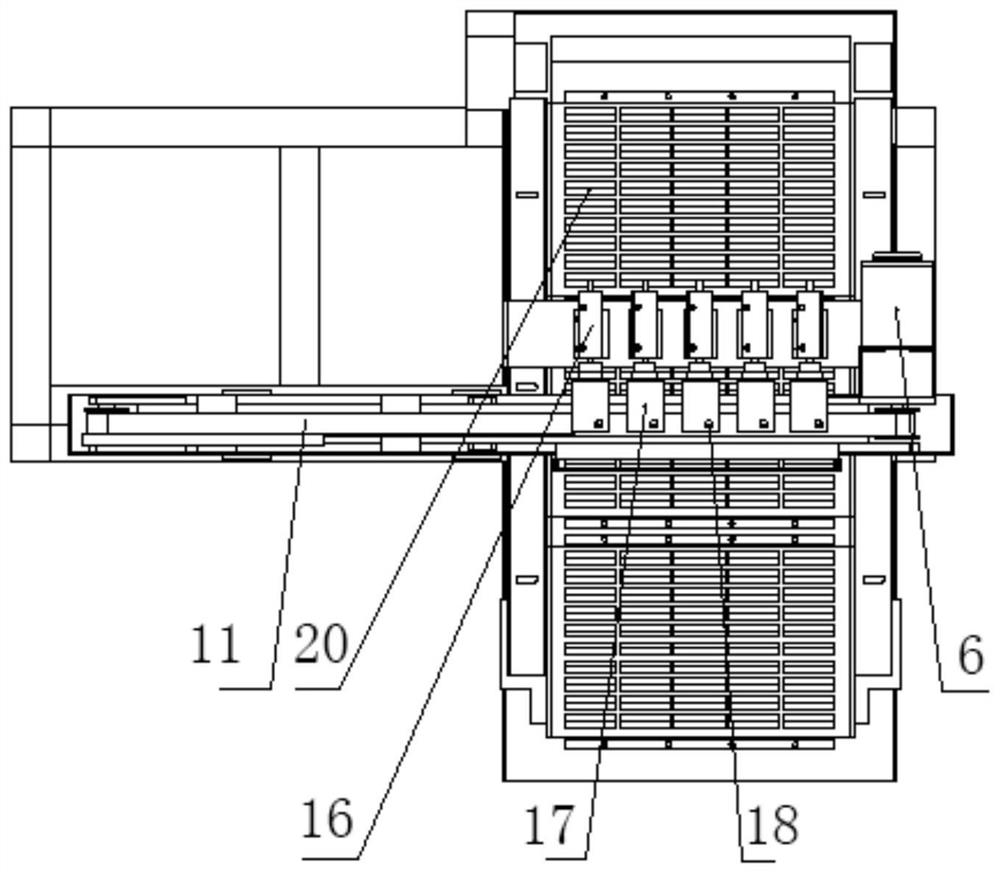

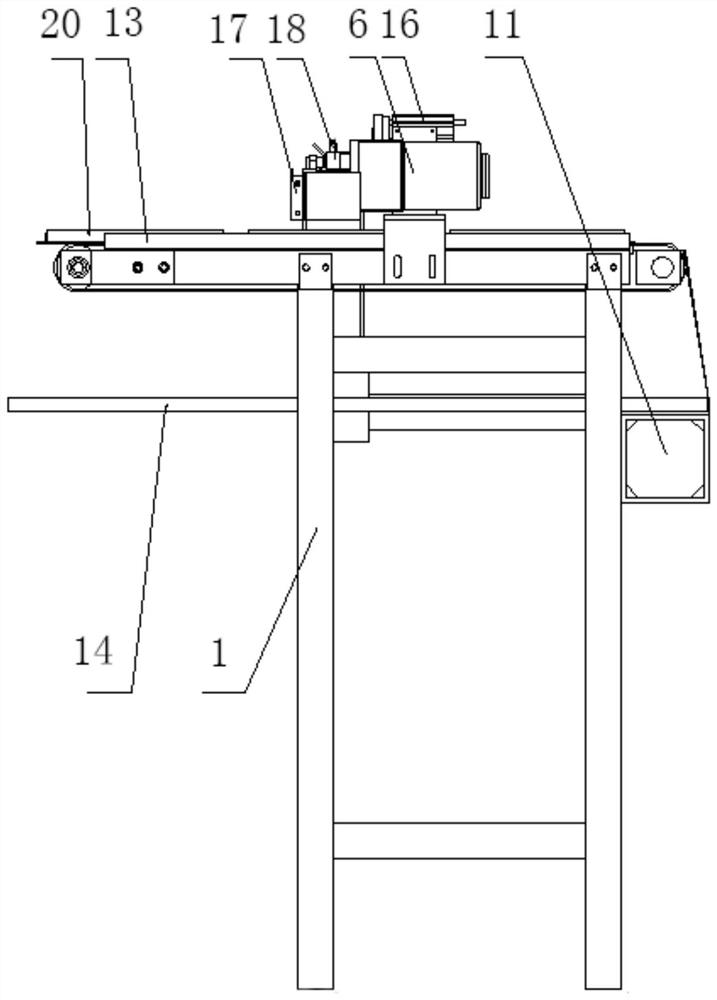

[0020] exist Figure 1 to Figure 4 In the schematic diagram of the present invention shown, the frame 1 is provided with a transfer mechanism, a material receiving mechanism and a water receiving box, and the material receiving mechanism includes a material receiving rack, a material receiving trough, a material receiving idler, a material receiving conveyor belt and Motor A, the material receiving mechanism is set on the frame through the material receiving frame 2, the material receiving trough 3 is set on the material receiving frame, two sets of material receiving rollers 4 in the material receiving trough, and the material receiving rollers pass the material receiving Conveyor belt 5 links to each other, and one end of a material receiving idler links to each other with motor A6 by belt drive. The transfer mechanism includes a support frame, a roller bearing seat, a roller, a conveyor belt and a motor B. The transfer mechanism is arranged on the frame by the transfer fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com