Mechanical winding device for textile technology

A winding device and mechanical technology, applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of yarn without crimping protection, poor use effect, and uneven winding, etc., to achieve convenience Effects of disassembly and maintenance, improvement of work efficiency, and improvement of winding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

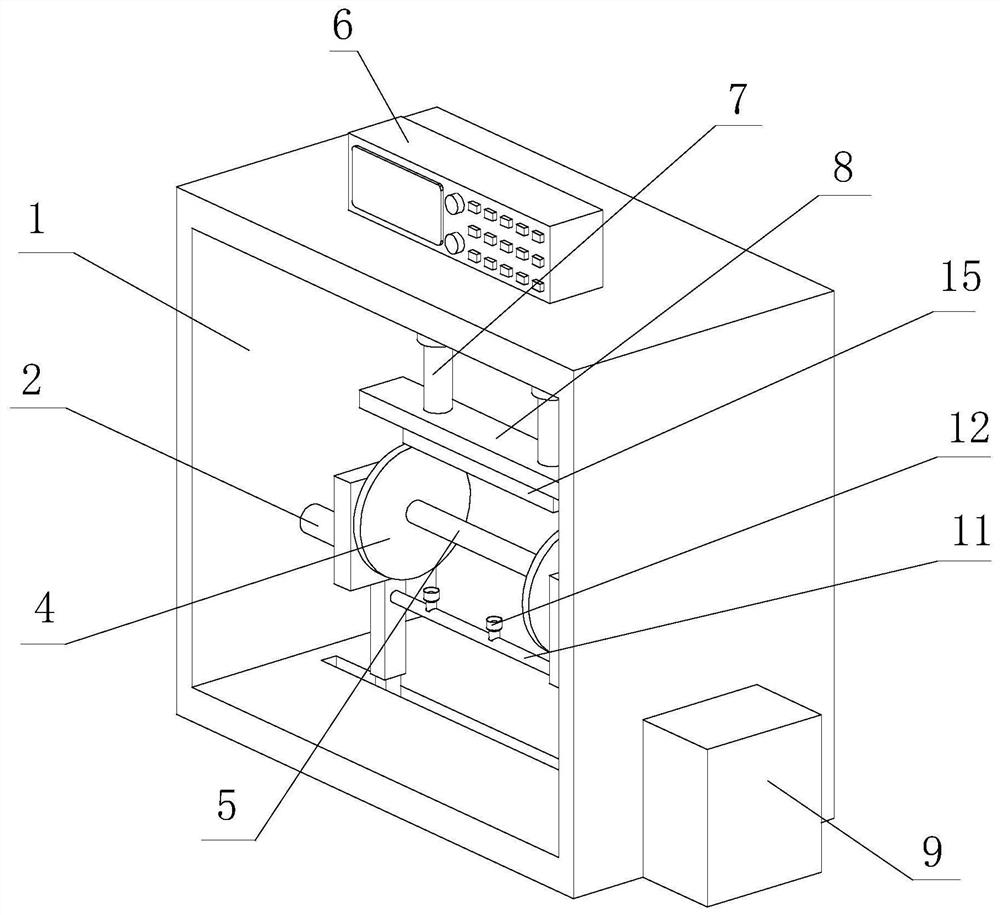

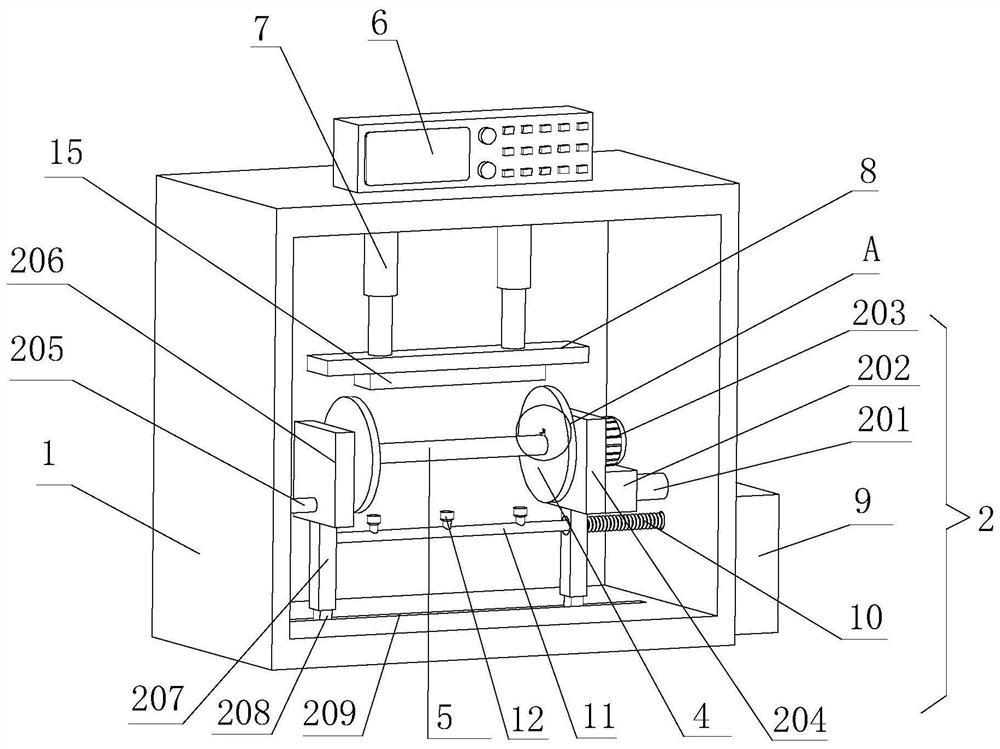

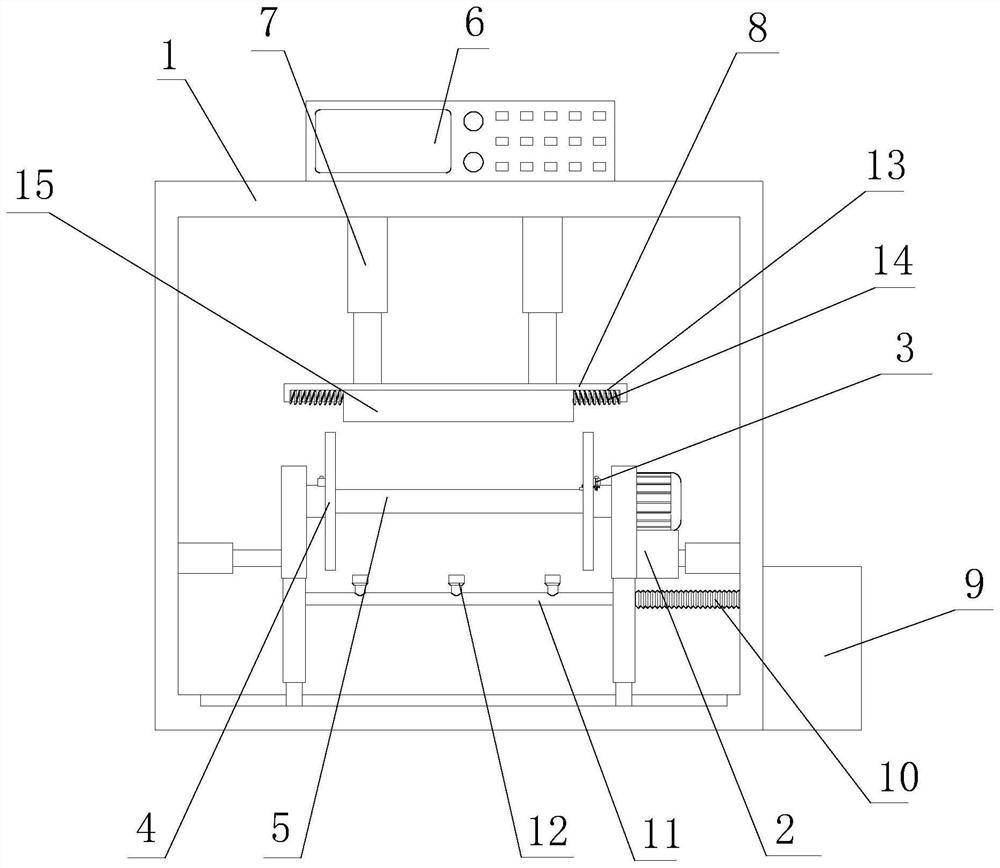

[0030] see Figure 1-5, the present invention provides a technical solution: a mechanical winding device for textile technology, including a main body 1, a moving winding device 2 and a dismounting device 3, the inner wall of the main body 1 is fixedly connected with a moving winding device 2, the moving winding One side of the wire device 2 is provided with a dismantling device 3, and one side of the mobile winding device 2 is fixedly installed with two reels 4 through the dismantling device 3, and one side of the reels 4 is fixedly connected with a winding column 5, and the main body The top outer wall of 1 is fixedly connected with the control cabinet 6, the top inner wall of the main body 1 is fixedly connected with the lifting cylinder 7, the bottom of the lifting cylinder 7 is fixedly connected with the moving plate 8, and the right outer wall of the main body 1 is fixedly connected with the fan dust removal box 9, the fan One side of the dust removal box 9 is fixedly co...

Embodiment 2

[0033] see Figure 1-Figure 7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution downwards: the dismounting device 3 includes a connecting seat 301, the top of the connecting seat 301 is provided with a clamping groove 302, and both sides of the clamping groove 302 are provided with The accommodation groove 303, the inner wall of the accommodation groove 303 is fixedly connected with a reset spring 304, the side of the reset spring 304 away from the accommodation groove 303 is fixedly connected with a reset block 305, and the side of the winding reel 4 away from the winding post 5 is fixedly connected with a clamp block 306, the top of the clamping block 306 is provided with a rotating block 307, the bottom of the rotating block 307 is fixedly connected with a rotating rod 308, the inside of the clamping block 306 is provided with a moving through hole 309, and the outer wall of the rotating rod 308 is provided with a trapezoidal groove ...

Embodiment 3

[0036] see Figure 1-Figure 3 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the mobile winding device 2 includes a right hydraulic cylinder 201, and one side of the right hydraulic cylinder 201 is fixedly connected with a fixed connecting plate 202 , the top of the fixed connection plate 202 is fixedly connected with the driving motor 203, the side of the fixed connection plate 202 far away from the right hydraulic cylinder 201 is fixedly connected with the right connection plate 204, and the inner wall of one side of the main body 1 is fixedly connected with the left hydraulic cylinder 205, the left hydraulic cylinder The side of the cylinder 205 away from the inner wall of the main body 1 is fixedly connected with a left connecting plate 206, and the bottoms of the left connecting plate 206 and the right connecting plate 204 are respectively fixedly connected with a connecting column 207, and the bottom of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com