Equipment with quick take-up function for cable

A fast, functional technology for the delivery of filamentous materials, thin material handling, transportation and packaging, which can solve problems such as inconvenient cable cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

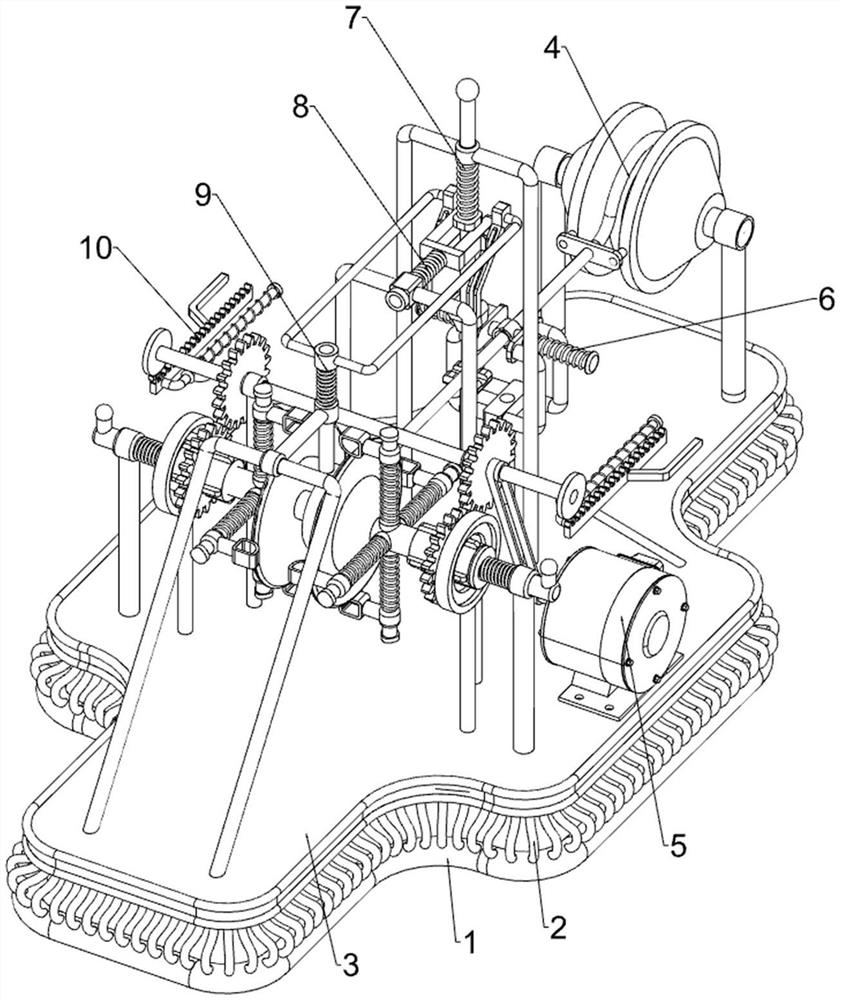

[0068] A device with a fast take-up function for cables, such as figure 1 As shown, it includes a first support frame 1, a second support frame 2, a base plate 3, a winding mechanism 4 and an automatic rotation mechanism 5, the first support frame 1 is provided with a second support frame 2, and the second support frame 2 is A base plate 3 is provided, and a wire winding mechanism 4 is arranged on the base plate 3 , and an automatic rotation mechanism 5 is arranged between the base plate 3 and the wire winding mechanism 4 .

[0069] When people need to take up the cable, people clamp the cable reel through the winding mechanism 4, and place the cable that needs to be wound on the winding mechanism 4, and at the same time, people wrap the cable at one end around the winding mechanism 4. On the reel, when people surround the cable at one end on the cable reel, people will turn on the automatic rotation mechanism 5, so that the automatic rotation mechanism 5 drives the winding me...

Embodiment 2

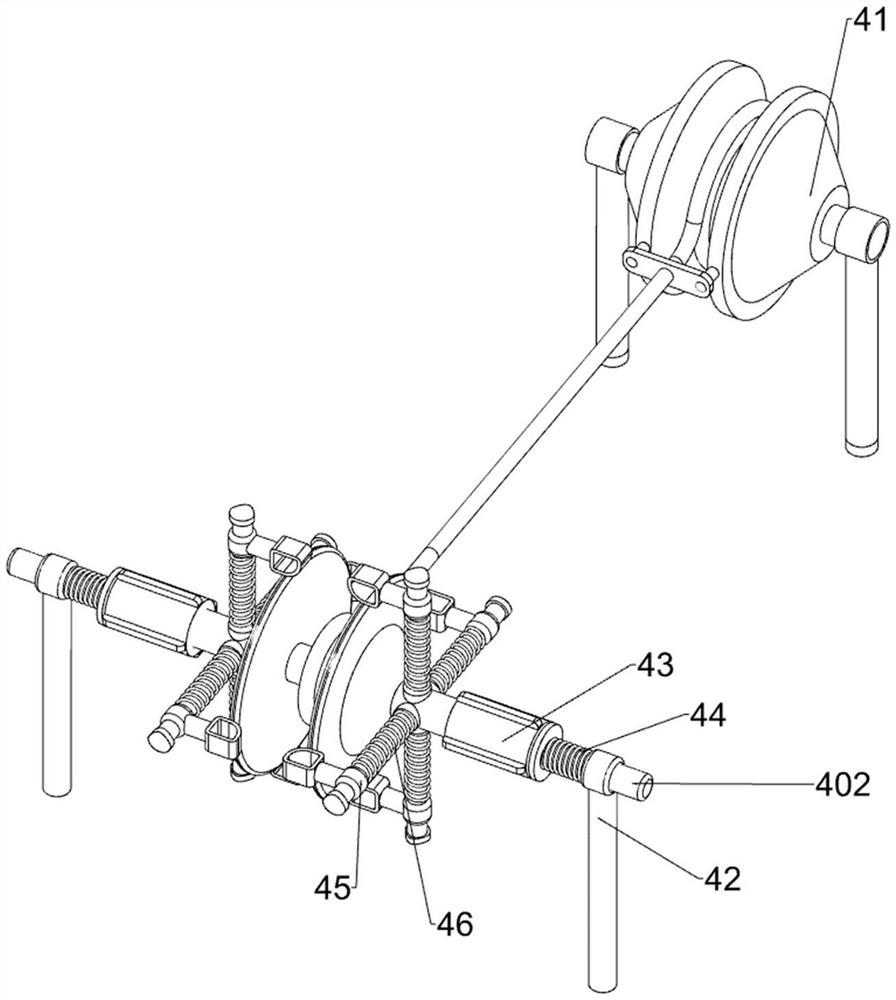

[0071] On the basis of Example 1, such as figure 2 As shown, the winding mechanism 4 includes a winding wheel 41, a first sliding support rod 42, a rotating connecting rod 402, a connecting column 43, a first spring 44, a sliding clamping block 45 and a second spring 46. The side rotation type is provided with a reel 41, the bottom plate 3 is provided with a first sliding support rod 42 on the front and rear sides of the upper middle part, and the two first sliding support rods 42 are all rotatably provided with a rotating connecting rod 402, and the rotating connecting rod 402 Connecting columns 43 are arranged on the top, and first springs 44 are sleeved inside the two rotating connecting rods 402. Both ends of the first spring 44 are respectively connected with the first sliding support rod 42 and connecting columns 43. The sliding clamping block 45 is provided in the uniform sliding type, and the second spring 46 is sleeved on the two sliding clamping blocks 45 , and the ...

Embodiment 3

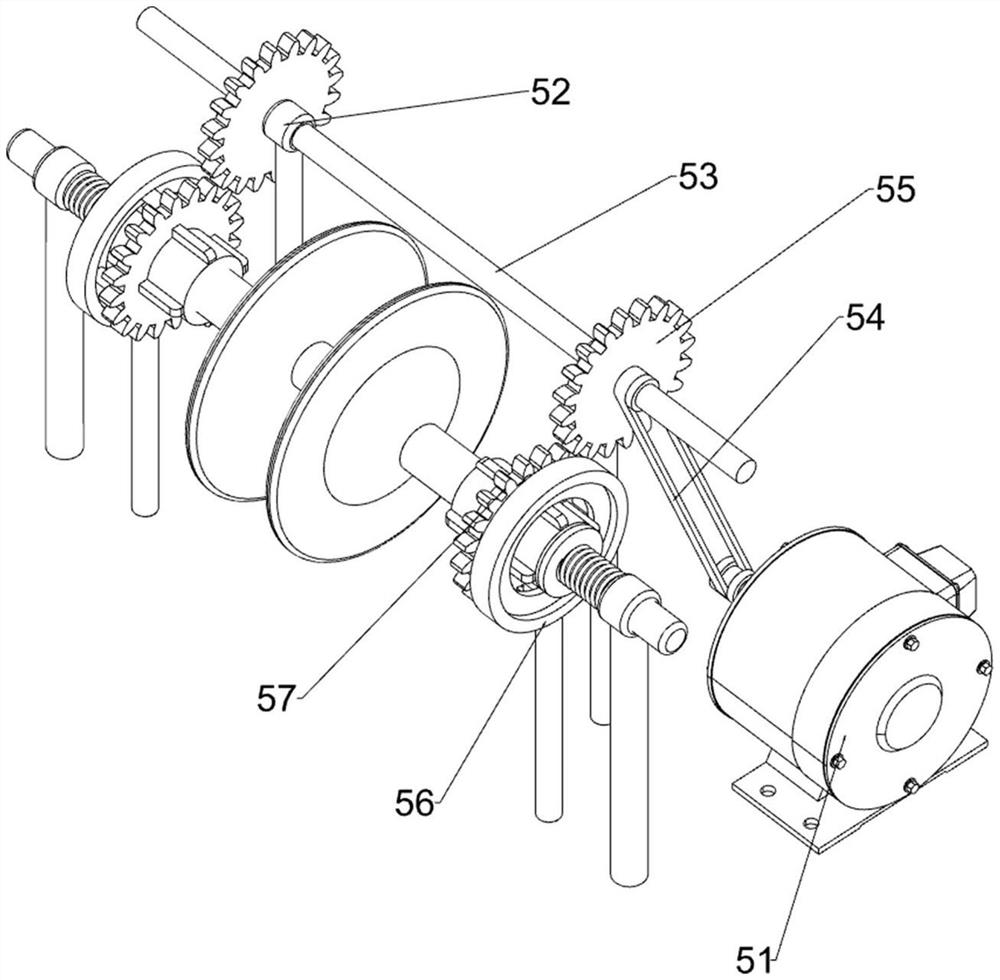

[0074] On the basis of Example 2, such as figure 1 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 and Figure 8 As shown, the automatic rotation mechanism 5 includes a motor 51, a rotating support rod 52, a rotating shaft 53, a transmission assembly 54, a first spur gear 55, a rotating connecting plate 56 and a second spur gear 57, and the front side of the upper middle part of the bottom plate 3 is equipped with a motor 51, the bottom plate 3 is equipped with a rotating support rod 52 on the front and rear sides of the upper middle part, and a rotating shaft 53 is arranged between the two rotating supporting rods 52, and a transmission assembly 54 is arranged between the rotating shaft 53 and the output shaft of the motor 51, and the rotating shaft 53 Both front and back sides are all provided with the first straight gear 55, are all provided with the rotating connecting disc 56 on the two connecting posts 43, are all provided with the second spur gear 57 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com