Full-process automatic graphite purification method

A graphite purification and whole-process technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems that the quality of the output graphite powder cannot be guaranteed, the quality of graphite purification is not uniform, and the system cannot be automated. To achieve the effect of rich functions, guaranteed graphite carbonization quality, continuous, stable and uninterrupted feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

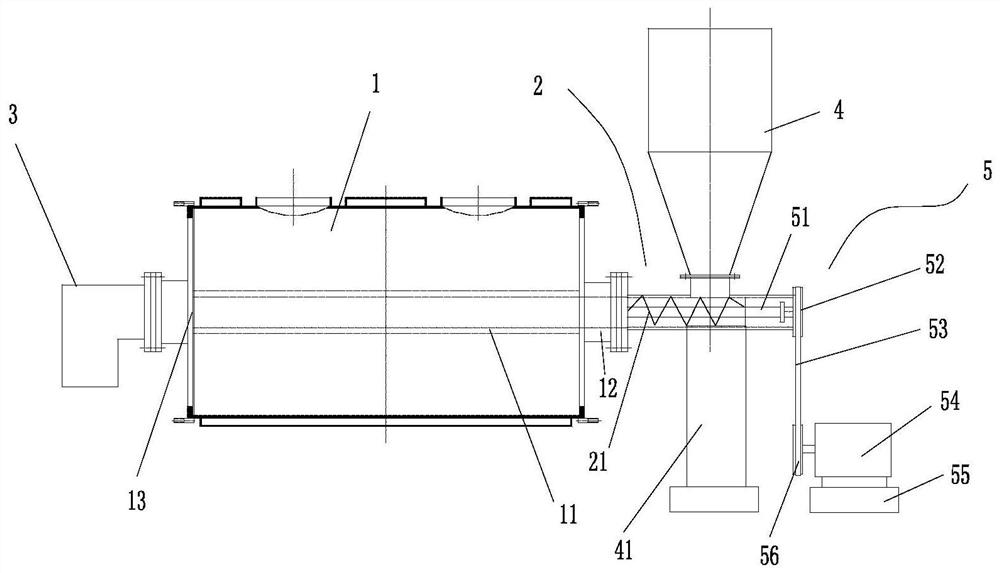

[0085] Such as Figure 1-7 , a system corresponding to the whole-process automatic graphite purification method, including a furnace body, a feeding device and a discharging device; the furnace body adopts a horizontal furnace body, the feeding device is arranged at the rear end of the furnace body, and the discharging device is arranged The front end of the body; there is a screw pushing device in the feeding device;

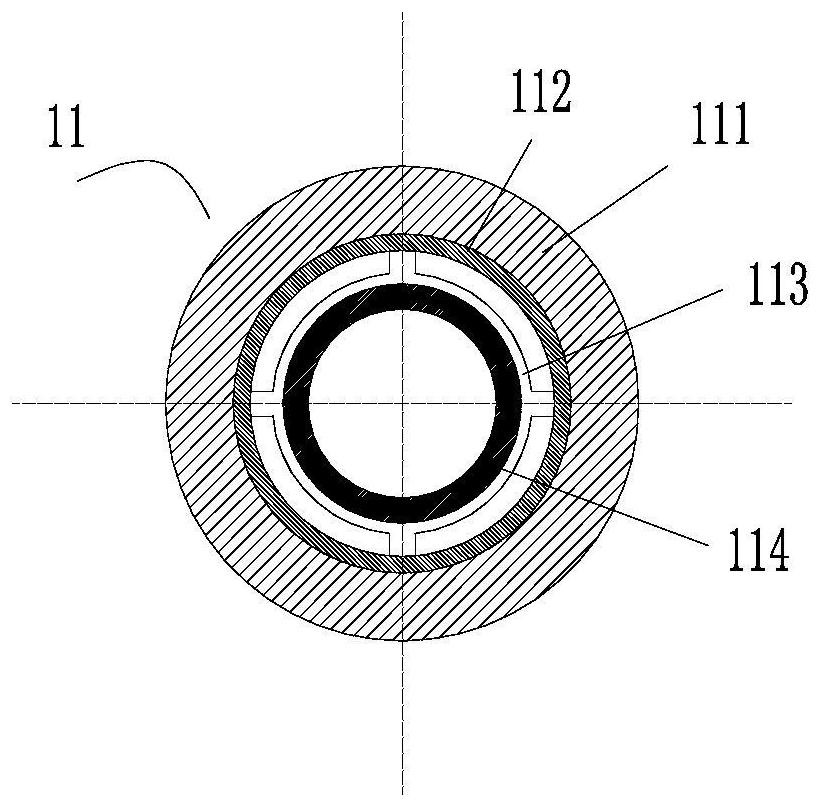

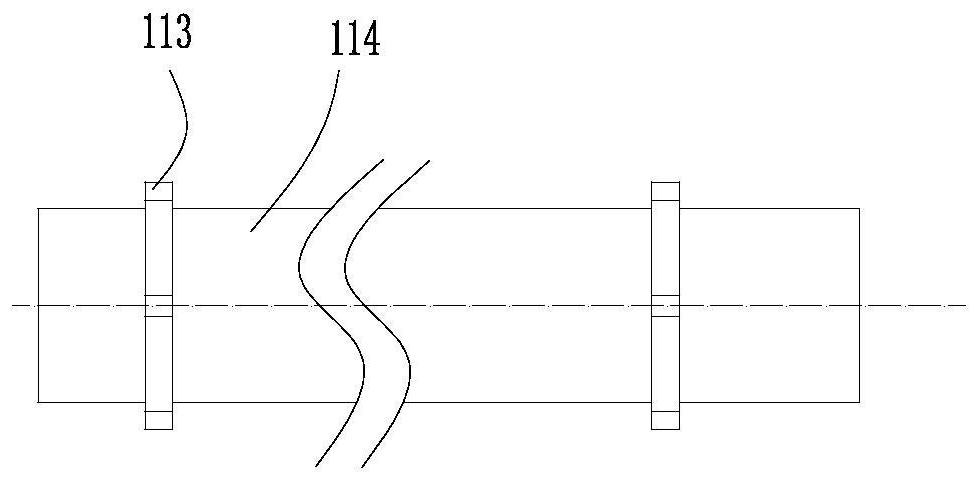

[0086] (1) Structure description of heating tube

[0087] The furnace body is provided with a heating tube; the heating tube includes a carbon tube (11), an inner tube (114) and a support ring (113); the inner tube is inserted in the carbon tube; there are at least two support rings; the support ring is arranged on the inner tube and Between the carbon tubes, the support ring is set on the inner tube; the support tube includes a ring body (115) and a plurality of protrusions (116) located on the outer wall of the ring body, and the ring body is a ring-shaped p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com