Constant-speed feeding device for purification agent for sewage treatment

A purification agent and delivery device technology, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of easy clogging, stable performance, incapable of uniform delivery, poor performance, etc., to achieve Improve resource utilization, avoid excessive falling, and facilitate the effect of discharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

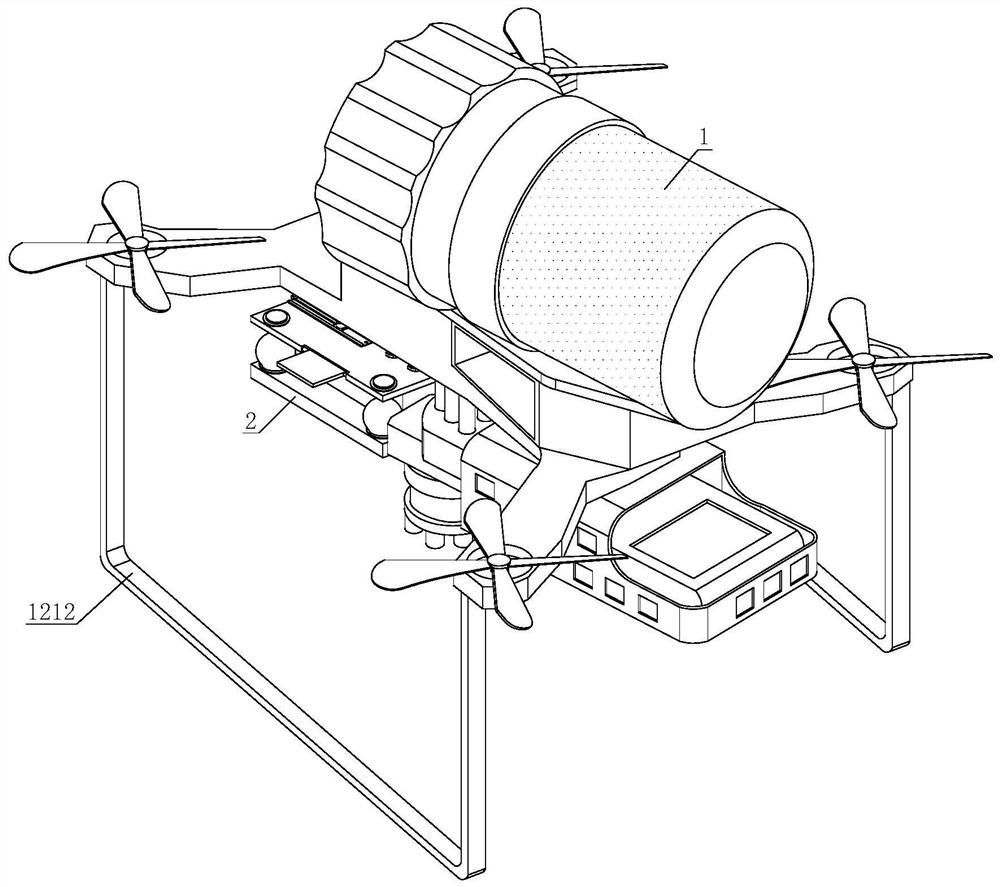

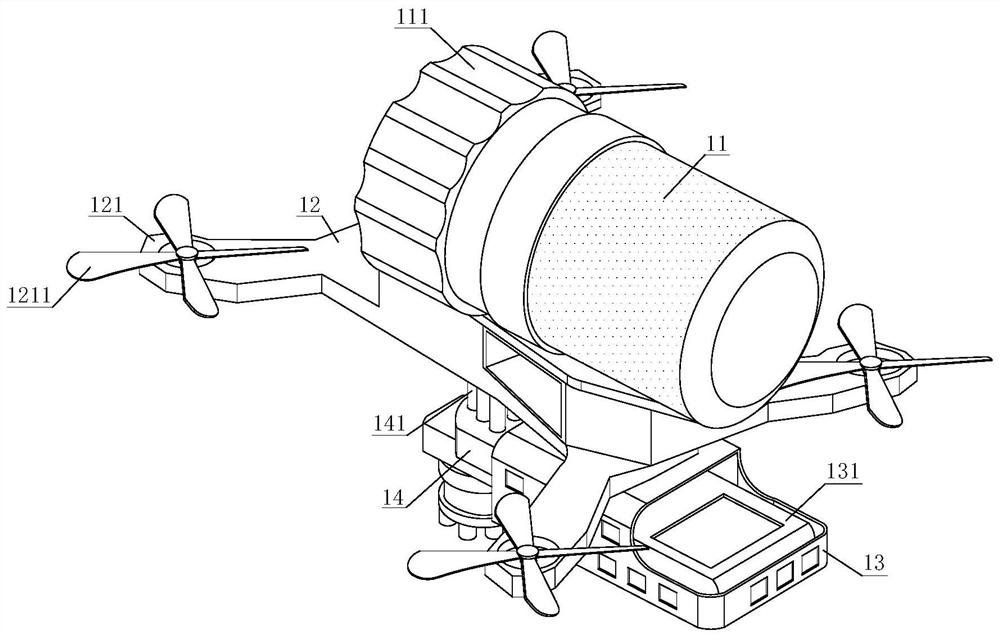

[0031] refer to Figure 1-2 , a uniform delivery device for purifying agents for sewage treatment, comprising a delivery mechanism 1 and a stability maintenance mechanism 2, the bottom end of the delivery mechanism 1 is fixed with a stability maintenance mechanism 2, and the delivery mechanism 1 includes a storage tank 11, a bearing bracket 12, a limit frame Frame 13 and discharge structure 14, a pump 111 is installed at one end of the storage tank 11, and the bottom end of the storage tank 11 is fixed with a bearing bracket 12, and the bottom end of the bearing bracket 12 is respectively equipped with a limit frame 13 and an outlet. The material structure 14, a remote sensing controller 131 is arranged in the inner cavity of the limit frame 13, and the bottom end of the bearing bracket 12 is also screwed with a stability maintenance mechanism 2; the four corners of the bearing bracket 12 are all provided with flanges 121, the convex The upper end of the edge portion 121 is eq...

Embodiment 2

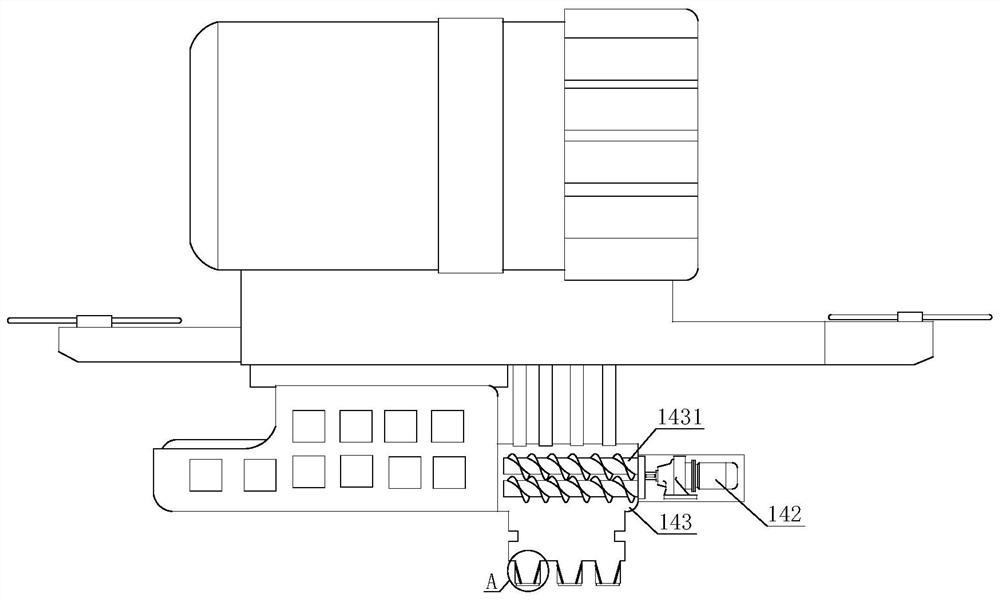

[0033] refer to Figure 2-4, a device for dispensing purification agents at a constant speed for sewage treatment. The discharge structure 14 includes an infusion tube 141, a gear motor 142, a discharge cavity 143 and a discharge tube 144. The upper end of the discharge cavity 143 is connected to the pump 111 through the infusion tube 141. And one side outer wall of the discharge chamber 143 is equipped with a reduction motor 142, the reduction motor 142 is electrically connected to the remote sensing controller 131, and the inner chamber of the discharge chamber 143 is equipped with a pair of roller stirring blade assemblies 1431; the output of the reduction motor 142 The end is connected to the roller stirring blade assembly 1431, and the bottom end of the discharge chamber 143 is provided with several groups of feeding pipes 144, and the inner walls of both sides of the feeding pipe 144 are fixed with inclined deflectors 1441, and the inclined deflectors 1441 The inclinatio...

Embodiment 3

[0035] refer to Figure 5-8 , a constant-speed injection device for purifying agents for sewage treatment. The stability maintenance mechanism 2 includes a stability maintenance platform 21, a slide assembly 22, and a mounting groove 23. A slide assembly 22 is installed on the upper surface of the stability maintenance platform 21, and one side of the stability maintenance platform 21 is close to the edge. The upper end surface is provided with a mounting groove 23, and a monitoring camera 231 is fixed in the inner cavity of the mounting groove 23; both sides of the stability maintenance platform 21 are processed with a fixing groove 211, and both ends of the fixing groove 211 are inserted with shock-absorbing glue Ball 2111, the bottom end of the shock-absorbing rubber ball 2111 is plugged into the bottom surface of the fixing groove 211, the upper end of the shock-absorbing rubber ball 2111 passes through the stability maintenance platform 21 and a gasket ring is sleeved on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com