A kind of efficient preparation method of bacterial cellulose/non-woven fiber composite mask base fabric

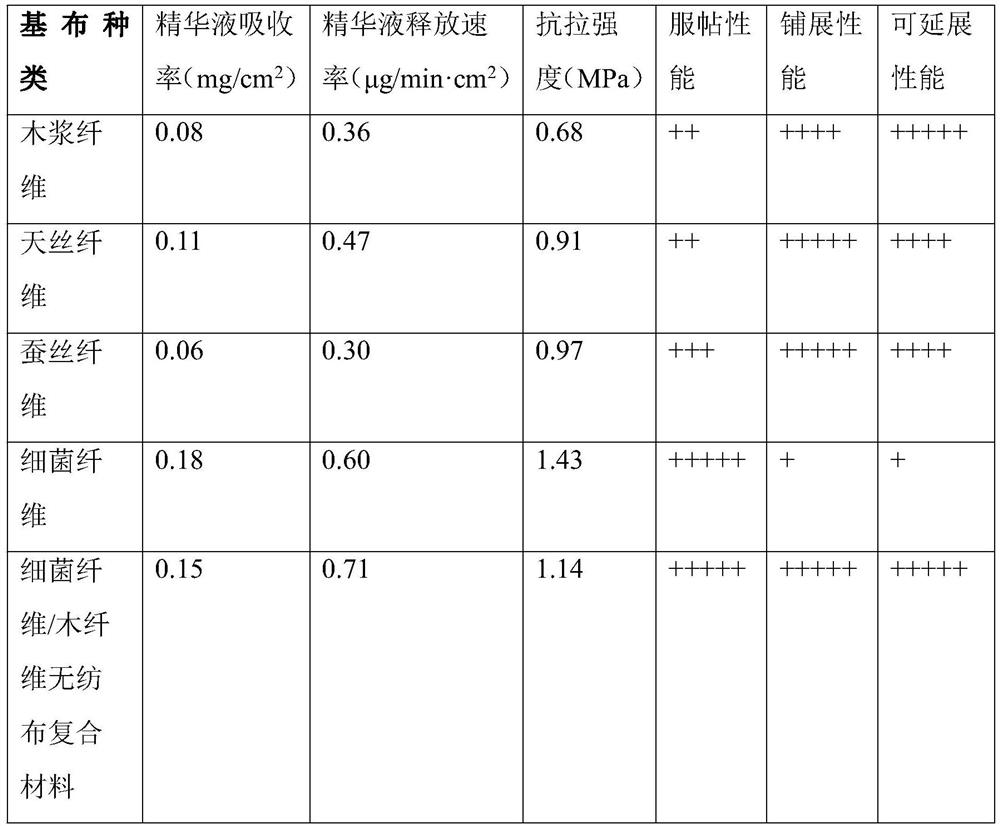

A technology of bacterial cellulose and non-woven fibers, applied in the field of materials, can solve the problems of precision sheet film equipment and difficulty in precision slicing that have not developed bacterial cellulose hydrogel materials, and achieve excellent absorption/release performance and uniform thickness. , the effect of excellent mechanical strength and ductility

Active Publication Date: 2022-06-03

NANJING FORESTRY UNIV

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Precise sectioning of bacterial nanofibers in macroscopic hydrogel state is clearly very difficult

So far, no sophisticated sheet-membrane device has been developed for bacterial cellulose hydrogel materials

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

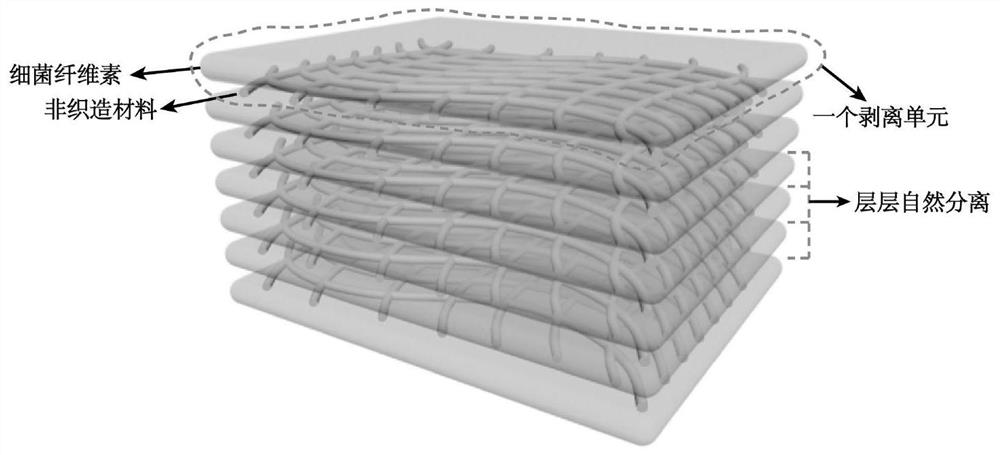

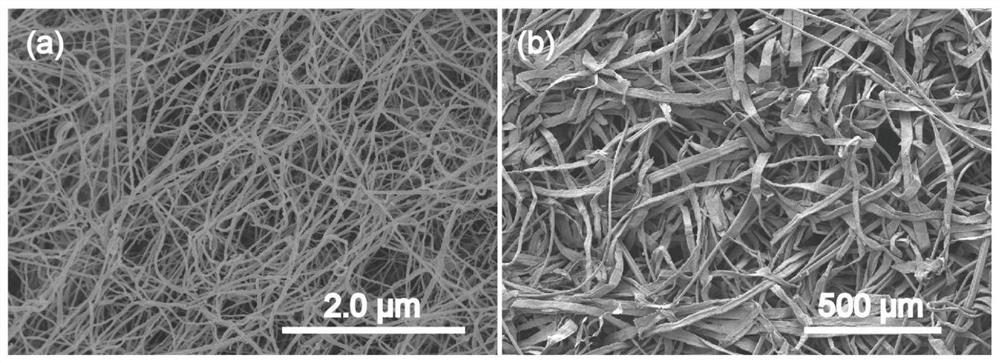

This application discloses a method for efficiently preparing bacterial cellulose / nonwoven fiber composite facial mask base fabric. During the period of fermentation and preparation of bacterial cellulose, the nonwoven fiber base fabric is placed in the culture medium according to the set interval time. The thickness of the bacterial cellulose is controlled by the interval time, and the bacterial cellulose / nonwoven fiber composite facial mask base fabric is prepared in situ by means of the biological fermentation process. This application realizes the continuous, batch and controllable preparation of bacterial cellulose / nonwoven material composite mask base fabric; the prepared bacterial cellulose / nonwoven material composite mask base fabric not only retains the excellent docile fit of bacterial cellulose At the same time, the ultra-thin bacterial cellulose film layer can be obtained by adjusting the interval culture time, which can not only ensure the good air permeability of the bacterial cellulose film, but also save the cost of material preparation to a certain extent.

Description

A kind of efficient preparation method of bacterial cellulose / non-woven fiber composite mask base cloth technical field The invention belongs to material technical field, be specifically related to a kind of bacterial cellulose / non-woven fiber composite facial mask base cloth Efficient preparation method. Background technique [0002] With the continuous improvement of people's living standards, more and more people begin to pay attention to personal skin care and repair. and At the same time, in modern society, people spend more and more time facing electronic display screens such as televisions, computers, and mobile phones, and their skin suffers from There is an increasing chance of damage from UV and electromagnetic radiation. Therefore, in recent years, beauty and skin care products have become more and more popular in people's daily life. played an increasingly important role. Among them, the mask products temporarily isolate the pollutants in the outside air...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): D06M15/05A61K8/97A61K8/73A61K8/02A61Q19/00D06M101/04D06M101/06D06M101/10

CPCD06M15/05A61K8/0212A61K8/731A61K8/97A61Q19/00D06M2101/04D06M2101/06D06M2101/10

Inventor 黄洋黄湘舟邓超尹纱胡辰尧肖惠宁

Owner NANJING FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com