Porous flat-bottom container and sample imaging detection method

A flat-bottomed container and flat-bottomed technology, applied in the field of molecular biology, can solve problems such as affecting the precision of digital PCR, voids in a single-layer droplet array, and unreasonable structural design of a multi-well plate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

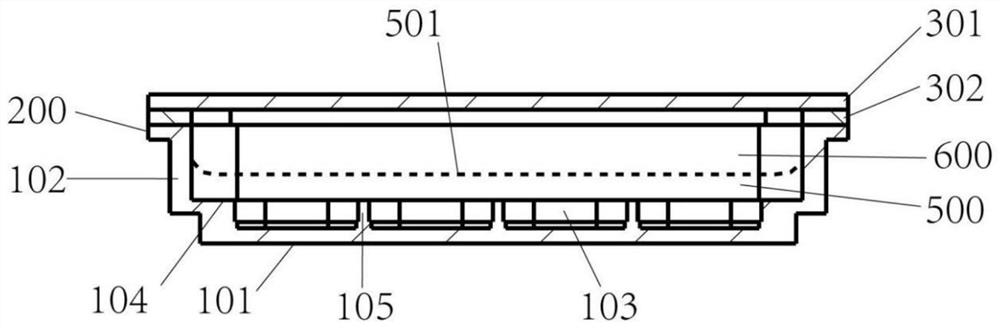

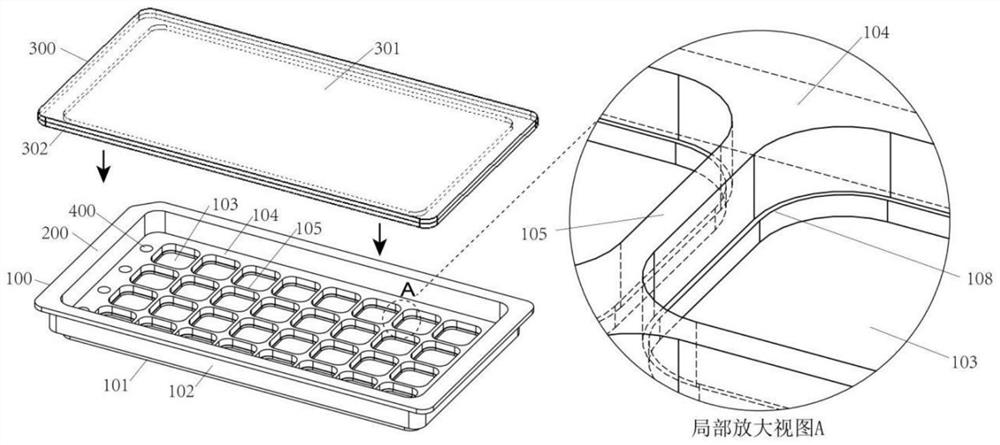

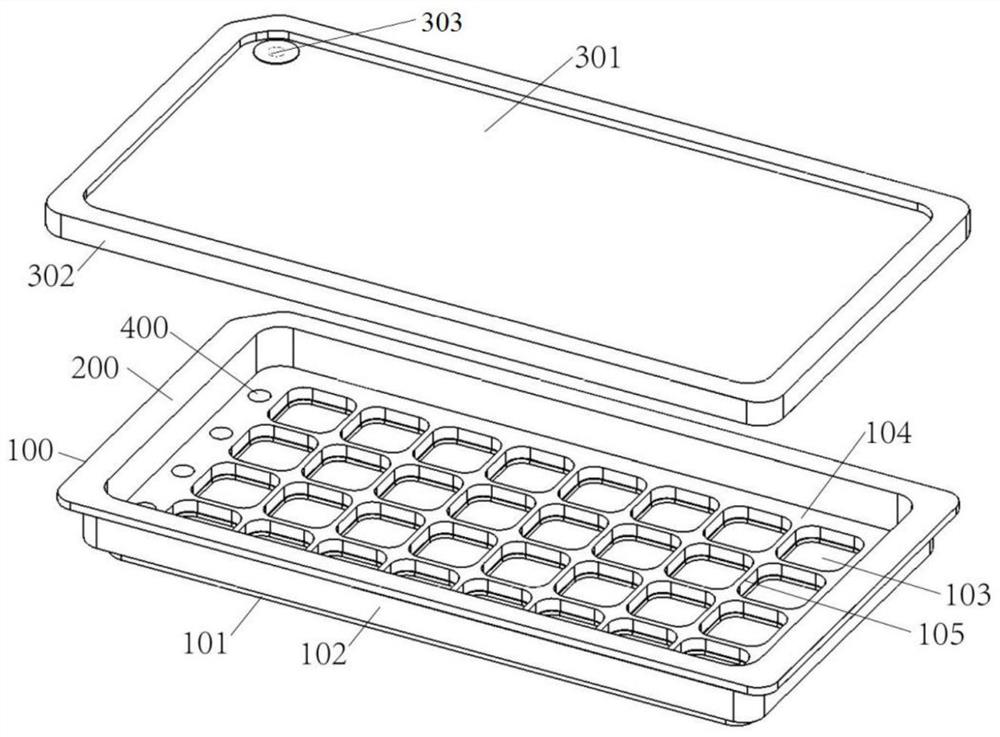

[0199] Perforated flat-bottomed containers as described herein, with figure 2 The shown flat-bottomed container is an example, the size of the bottom plate 101 is 80mm×40mm, the thickness of the bottom plate 101 is 1mm; The thermal frame 302 and the high light-transmitting sealing member 301 are integrally formed, and the height of the sealing and heat-insulating frame 302 is 2mm, and the height of the high-transparency sealing member 301 is 1mm, and there is an EVA adhesive layer around the edge of the sealing and heat-insulating frame, In order to realize the bonding and sealing connection of the surrounding components and the sealed heat insulation frame; the height of the edge rib 104 is 5 mm, and the thickness of the edge rib 104 is 5 mm; the height of the inner hole rib 105 is 5 mm, and the thickness of the inner hole rib 105 1mm. At the bottom of the inner hole reinforcing rib 105 and the edge reinforcing rib 104, an edge step 108 is arranged around the flat-bottomed ...

Embodiment 2-8

[0207] Example 2-The porous flat-bottomed container described in Example 8, its operation process is as in Example 1, and the specific parameters of the difference from the porous flat-bottomed container in Example 1 are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com