Adsorption device, lamination equipment, and lamination method for substrates

A technology of adsorption device and pressing equipment, which is applied in the direction of identification device, instrument, etc., can solve the problems of line damage, low efficiency, and inability to realize mass production, and achieve the effect of meeting mass production requirements and smooth adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

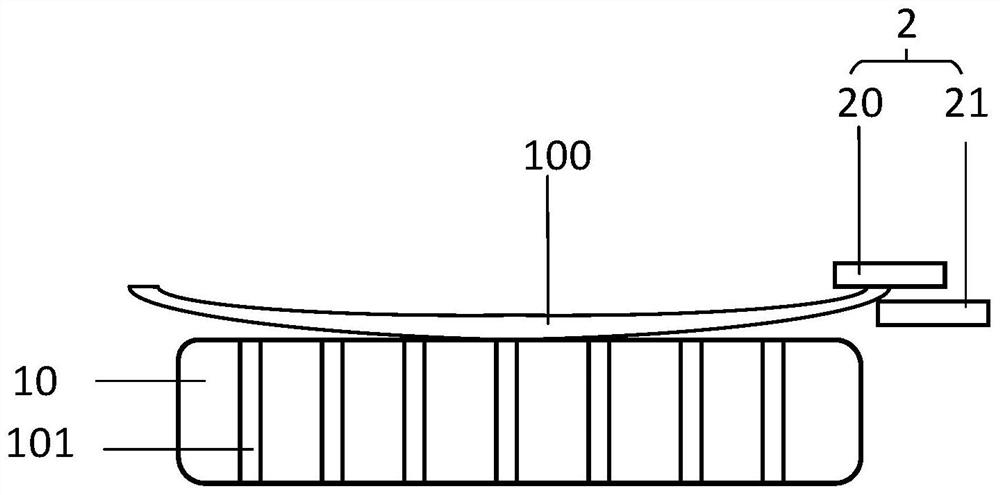

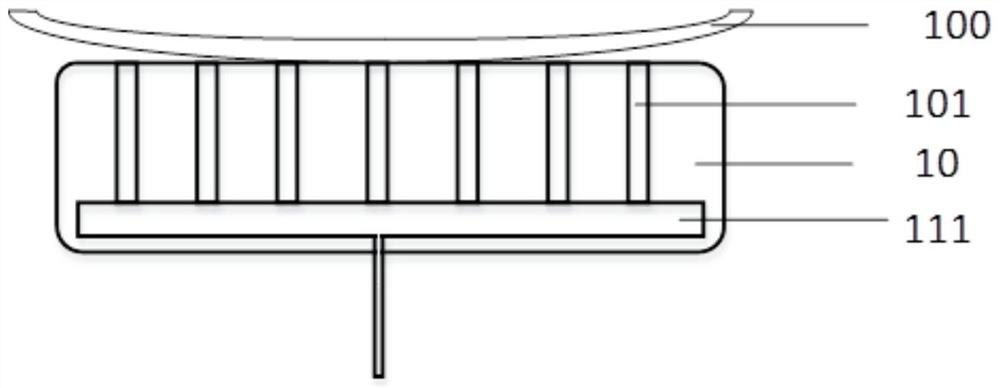

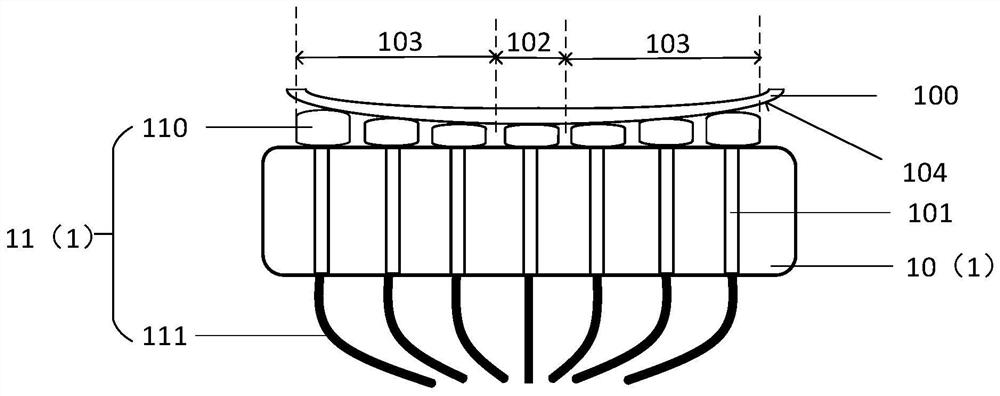

[0022] See Figure 3. FIG. 3 is a schematic structural diagram of an adsorption device according to an embodiment of the present application. This application provides

[0023] As shown in FIG. 3, in the embodiment of the present application, the stage 10 includes a plurality of adsorption holes 101, and the adsorption holes

[0024] Continuing to FIG. 3, each of the adsorption mechanisms 11 includes a soft suction nozzle 110 and a vacuum pipe 111, each of the soft

[0025] In this embodiment, each of the soft suction nozzles 110 is disposed in a corresponding one of the suction holes 101 close to the base

[0026] As a preferred embodiment, the cross-sectional shape of the soft suction nozzle 110 includes, but is not limited to, a circle, a square, to

[0029] In some other embodiments, the connection between the soft suction nozzle 110 and the suction hole 101 includes but is not limited to

[0030] It should be noted that since the substrate 100 is warped toward the side away fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com