Method for improving metal soft magnetic characteristics

A metal soft magnetic, characteristic technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of product permeability and saturation value performance improvement, cumbersome preparation process, incomplete use and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

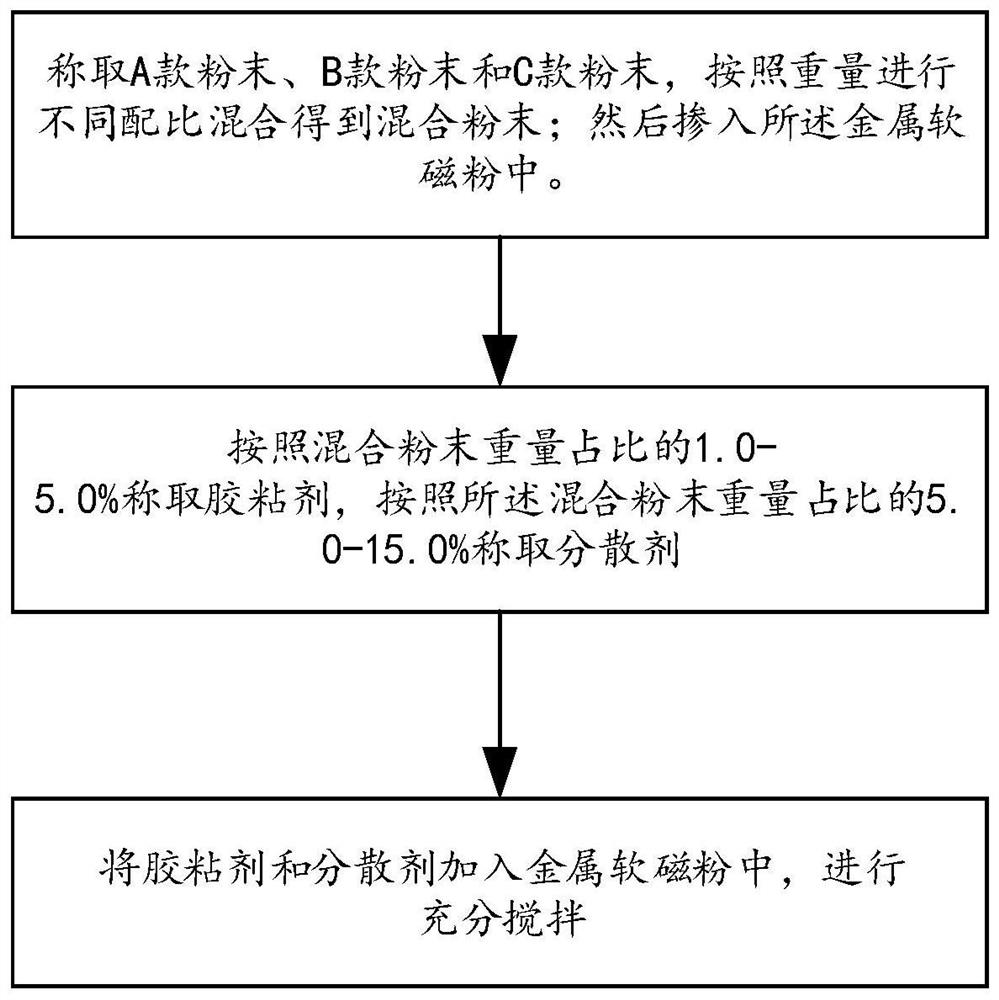

Method used

Image

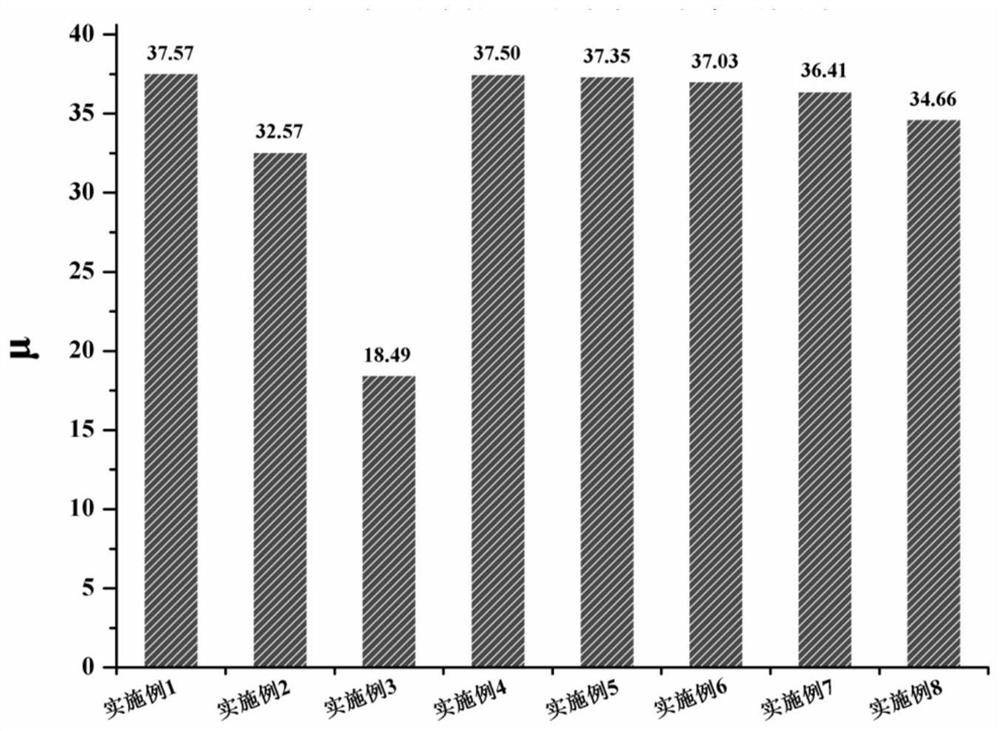

Examples

Embodiment 1

[0034] Embodiment 1: Take a single group of A powder. The parameters of the magnetic ring pressed in the test are: outer diameter 1.4cm, inner diameter 0.8cm, weight ≈2g, pressure 5-7t, holding time 2-4s, number of coils 13.5N.

Embodiment 2

[0035] Embodiment 2: Take a single group of B powder. The parameters of the magnetic ring pressed in the test are: outer diameter 1.4cm, inner diameter 0.8cm, weight ≈2g, pressure 5-7t, holding time 2-4s, number of coils 13.5N.

Embodiment 3

[0036] Embodiment 3: single component C type powder. The parameters of the magnetic ring pressed in the test are: outer diameter 1.4cm, inner diameter 0.8cm, weight ≈2g, pressure 5-7t, holding time 2-4s, number of coils 13.5N.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com