Cell battery cooled by cooling plates in radiator configuration

A single battery and cooling fin technology, applied to battery components, batteries, secondary batteries, etc., can solve the problems of occupying space, limiting the number of single batteries, and not describing the positioning of single battery cooling fins, etc., to increase The effect of capacity and heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

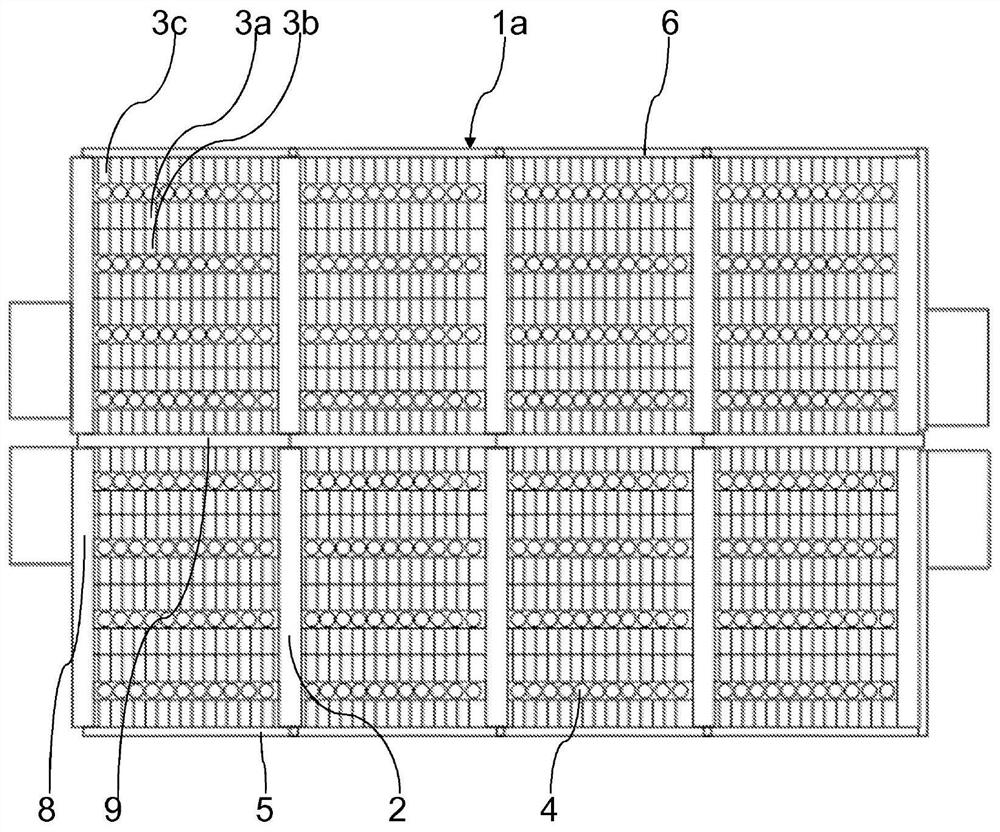

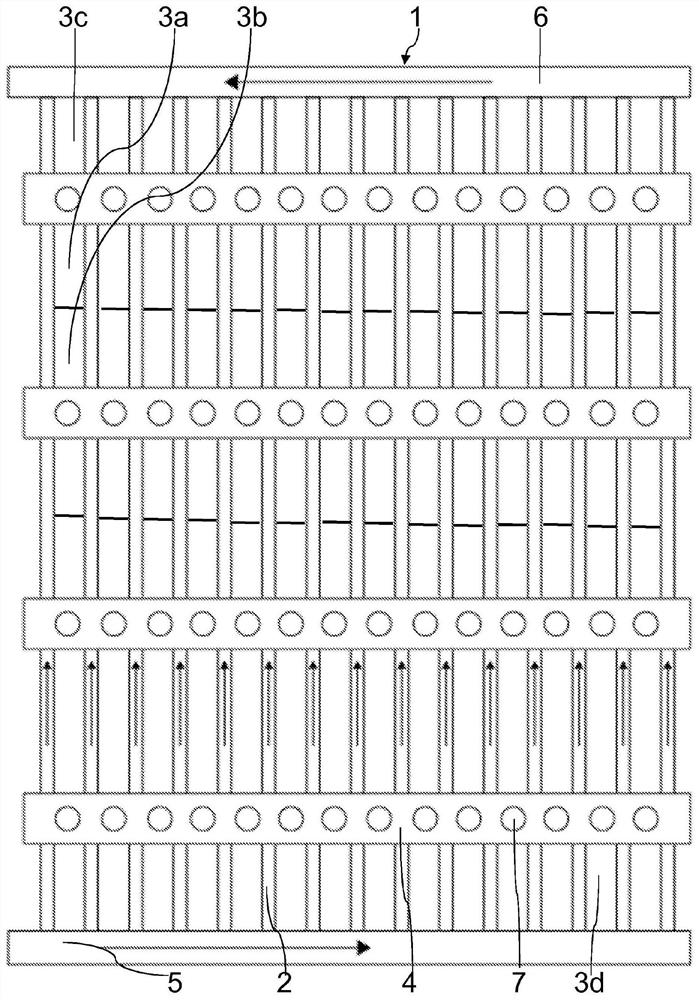

[0029] exist figure 1 with figure 2 In , only a single assembly bar 4, a single vent 7, a single cooling plate 2, and two cells 3a, 3b associated to all two associated cells are shown for simplicity, but for A description also refers to all equivalent elements.

[0030] refer to figure 2 , the present invention relates to a battery pack 1 comprising cooling fins 2, single cells 3a, 3b, 3c, 3d generating current, assembly rods 4, and inlet manifolds 5 and outlet manifolds 6 for cooling liquid, advantageously but not exclusively, The main component of the cooling liquid is the water circulating in the cooling fin 2, as shown by the arrow.

[0031] According to the invention, the cooling fins 2 are distributed in a plurality of parallel rows. Each row extends from the inlet manifold 5 to the outlet manifold 6 to ensure the circulation of the cooling liquid in the battery pack 1 .

[0032] Two single cells 3a, 3b storing and releasing electrochemical energy, advantageously ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com