Physical temperature limiting pot

A pot and physical technology, applied in home utensils, kitchen utensils, overflow prevention, etc., can solve the problems of food paste, pot burning deformation, etc., to achieve the effect of improving life expectancy, responsiveness, and improving user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following examples illustrate the invention, but the invention is not limited by these examples. Modifications to the specific implementation of the present invention or equivalent replacement of some technical features without departing from the spirit of the present invention should be included in the scope of the technical solution claimed in the present invention.

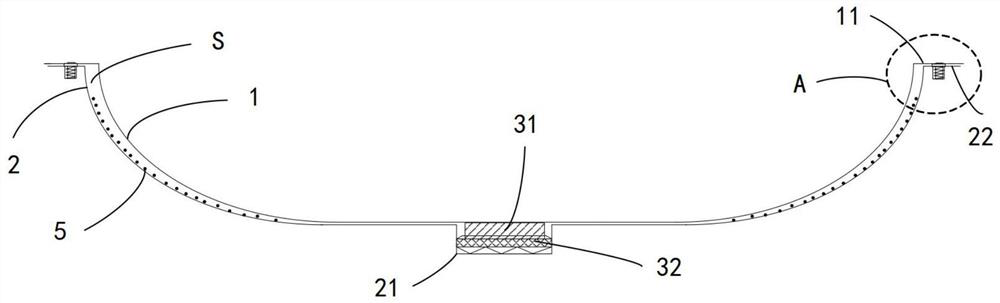

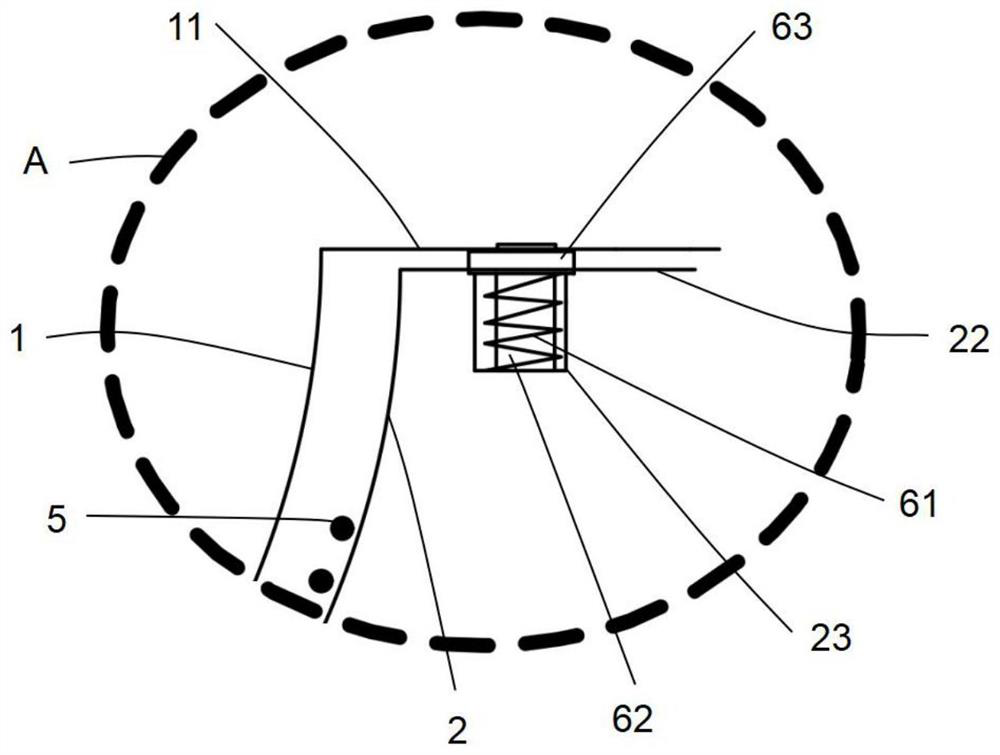

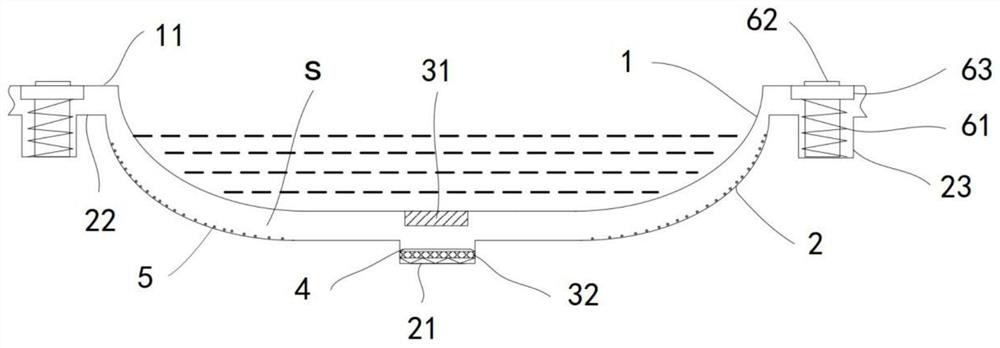

[0022] see Figure 1-3 , this embodiment provides a physically temperature-limited pot, including an inner layer 1, an outer layer 2, a switch unit (not shown in the figure) and an elastic mechanism (not shown in the figure), wherein the inner layer 1 is a heat-conducting layer . The outer layer 2 is a heat generating or heat transfer layer, and the outer layer 2 can be movably arranged on the periphery of the inner layer 1 . There is a gap S between the outer layer 2 and the inner layer 1 , and the size of the gap S can change with the movement of the outer layer 2 . The switch unit is respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com