Special-shaped inclined plate filler and inclined plate filler precipitation device

A packing sedimentation and sloping plate technology, which is applied in the feeding/discharging device of the settling tank, sedimentation separation, flocculation/sedimentation water/sewage treatment, etc., can solve secondary pollution, difficult cleaning of honeycomb packing, and limited sedimentation area and other problems to achieve the effect of avoiding water impact, increasing the effective sedimentation area, and increasing the sedimentation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

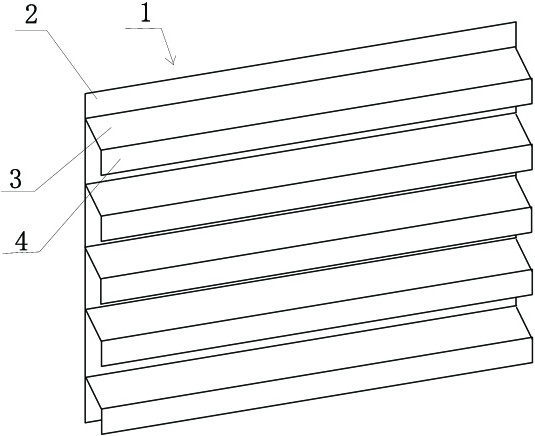

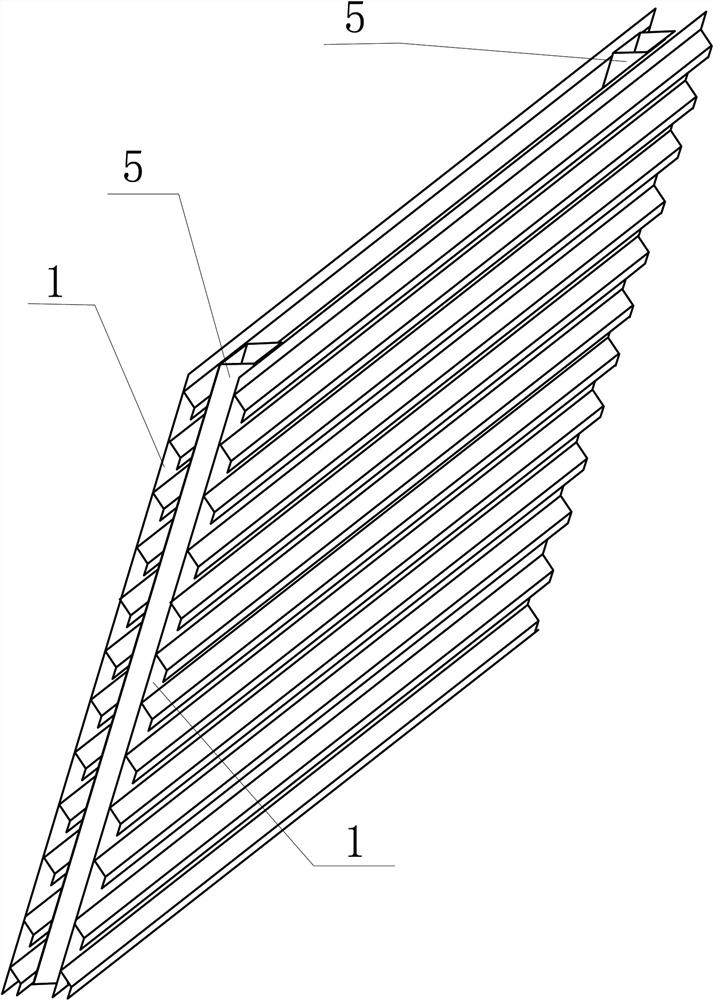

[0025] Further, as a specific embodiment of the special-shaped sloping plate packing according to the present invention, the connecting boundary line between the sloping plate body 2 and the strip plate 3 is a horizontal line or an inclined line.

Embodiment approach

[0026] Further, as a specific embodiment of the special-shaped sloping plate packing according to the present invention, the connection boundary between the sloping plate body 2 and the strip plate 3 is inclined upward from the water inlet side to the water outlet side.

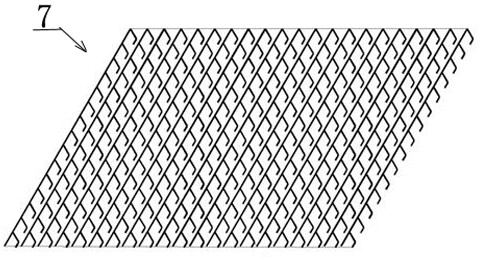

[0027] Further, as a specific embodiment of a special-shaped sloping plate packing according to the present invention, such as figure 1 As shown, the angle between the body and the horizontal plane is 60°, and the angle between the strip plate 3 and the inclined plate body 2 is 60°. In this way, the structure is stable, and the passing speed of the water flow is not affected, so it has high versatility. The special-shaped sloping plate packing 7 can be made of PVC material, the strip plate 3, the flange 4 and the sloping plate body 2 are arranged as an integral structure, and the distance between adjacent sloping plate bodies 2 is 46 mm. The size of the special-shaped sloping plate filler 7 and the water pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com