Plate planing machine

A technology for board machine and planer, which is applied in the field of planer, can solve the problems of increasing labor cost, insufficient precision, and a lot of labor, and achieves the effect of reducing labor cost, high precision and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further elaborated below in conjunction with the examples, and the described examples are only some examples of the present invention, and these examples are only used to explain the present invention, and do not constitute any limitation to the scope of the present invention.

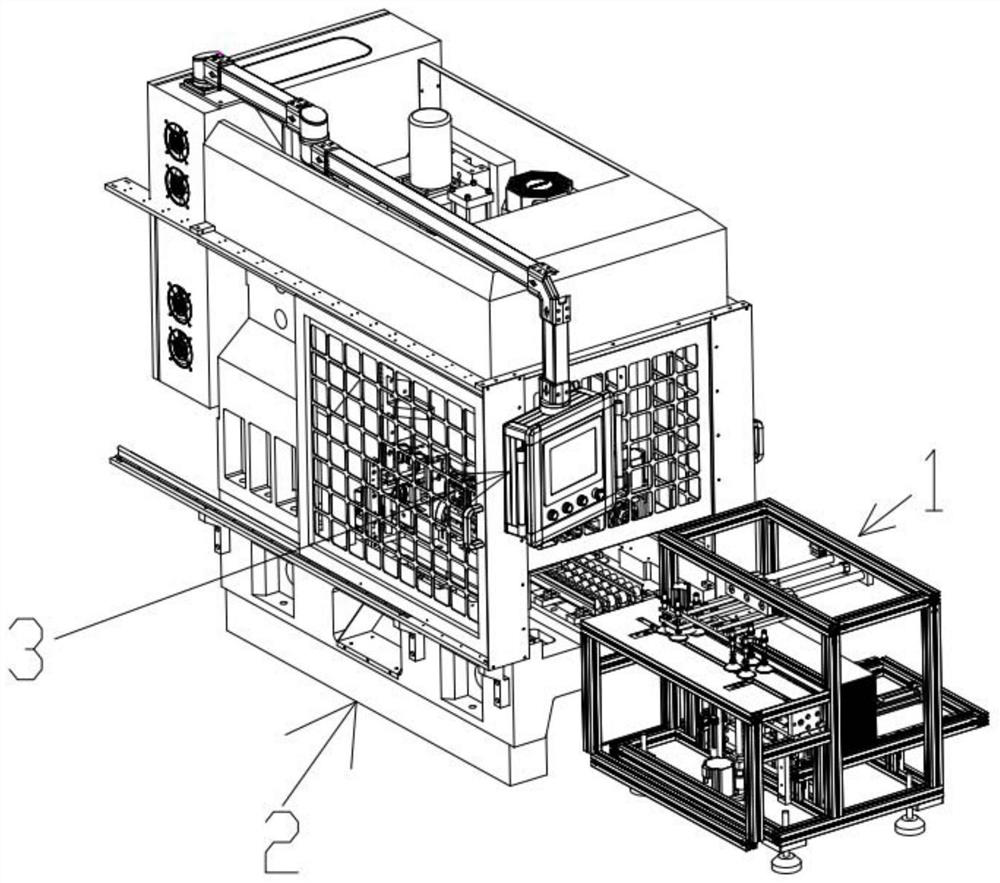

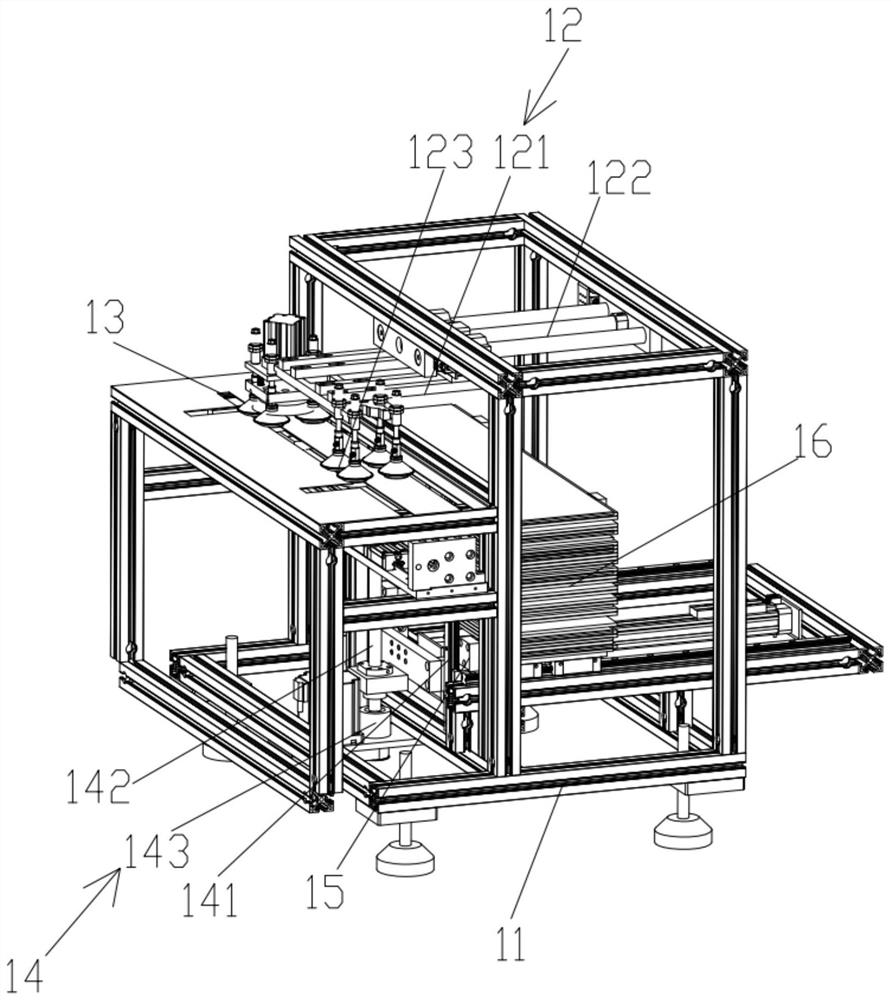

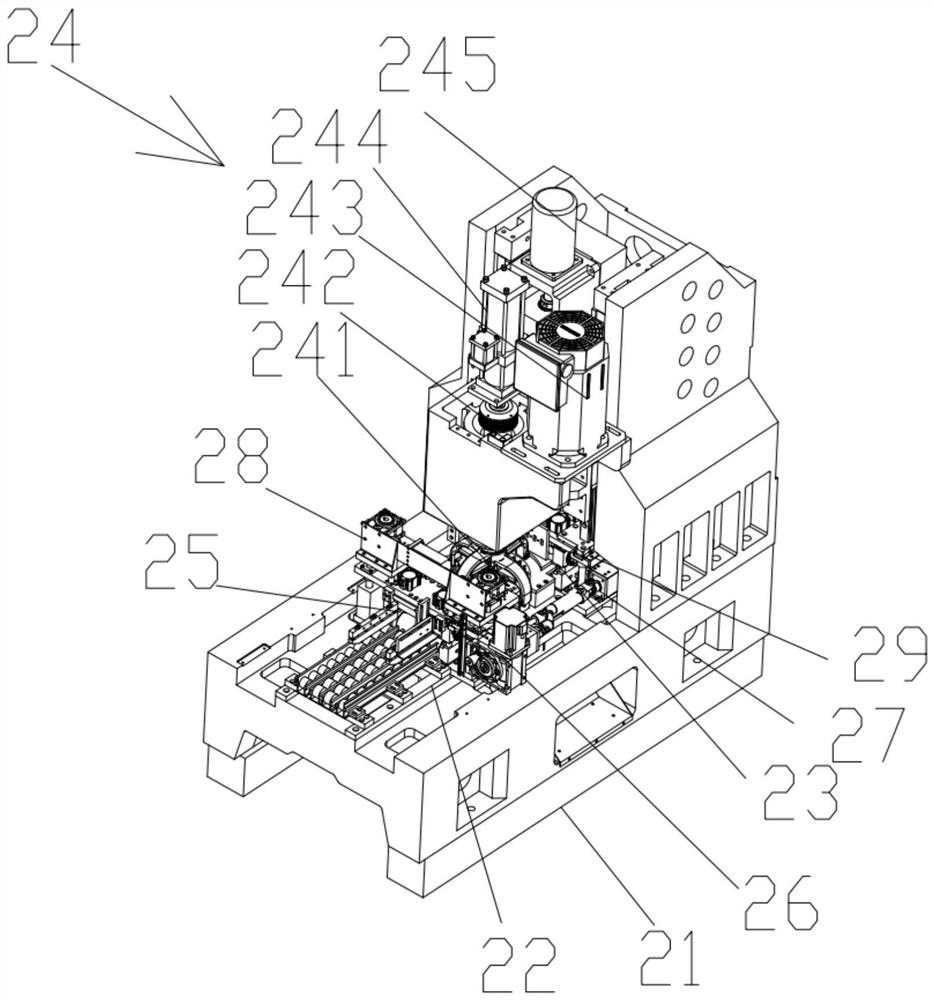

[0022] See Figures 1 to 3 , The present invention provides a planer, comprising an automatic feeding mechanism 1, a planing mechanism 2, a PLC control system 3, the automatic feeding mechanism 1 includes a frame 11, a feeding manipulator 12, a sheet conveying device 13, Lifting mechanism 14, raw material placement rack 15;

[0023] The raw material placement frame 14 is used to place the sheet material 16;

[0024] The used feeding manipulator 12 is installed on the frame 11, and is used to transport the sheet material 16 from the raw material placement frame 15 to the sheet material conveying device 13;

[0025] The board conveying device 13 is used to convey th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com