A kind of jointable concrete two-way assembly plate and its assembly method

A technology for assembling slabs and concrete, which is applied to floors, instruments, and geometric CAD. It can solve the problems of poor economy, high cost, and increased workload of horizontal reinforcement, so as to save the wiring and punching process, improve work efficiency, and implement flexibly. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

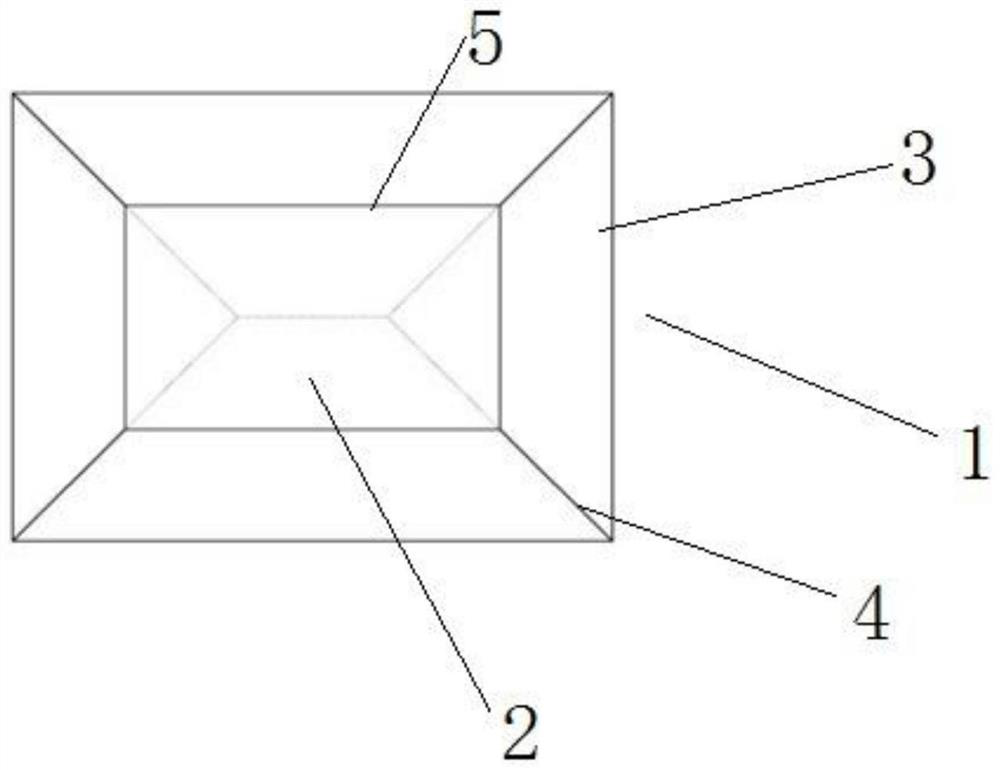

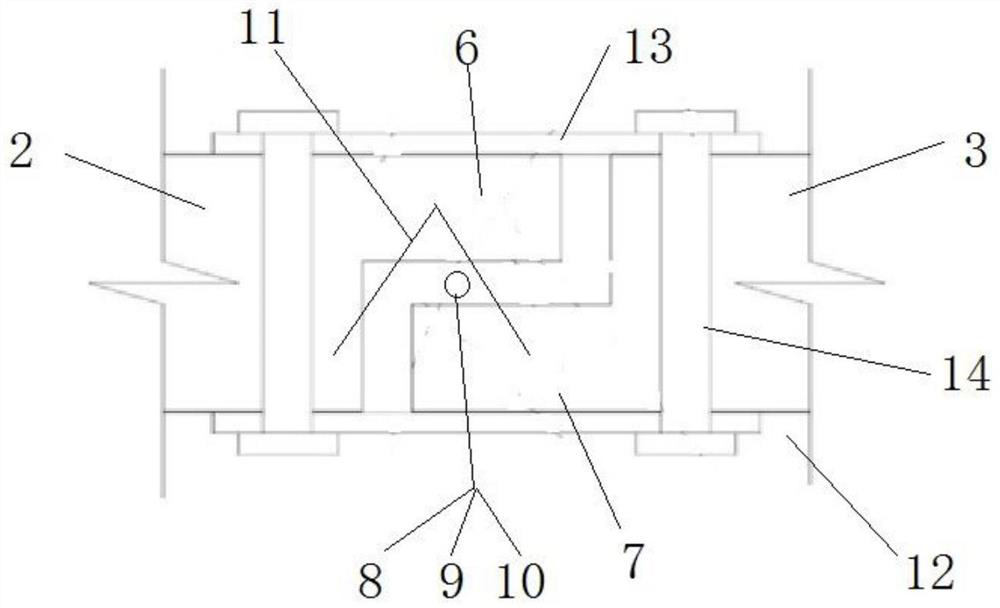

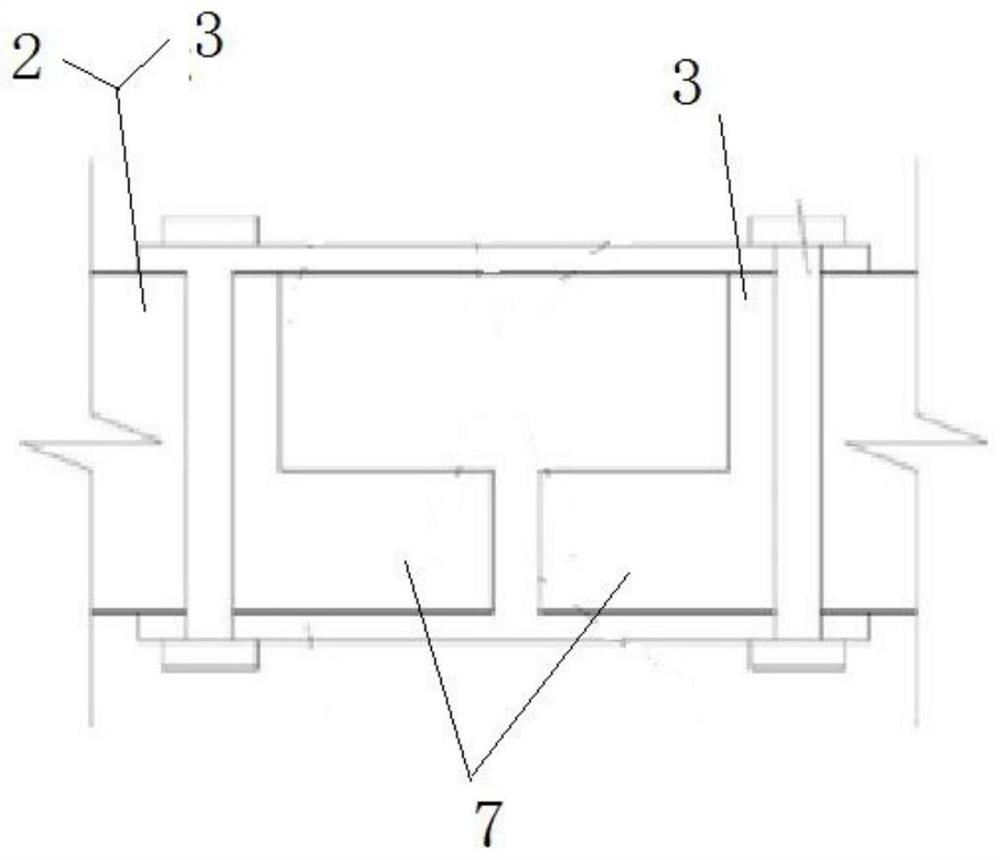

[0052] Such as figure 1 As shown, a concrete two-way assembly panel that can be spliced includes a panel body 1, the panel body 1 is rectangular or square, and the panel body 1 includes an intermediate panel 2 that is located in the middle of the panel body 1 and is rectangular or square like the panel body 1, And four groups of trapezoidal plates 3 arranged around the four sides of the middle plate 2, with the four sides of the plate body 1 as the bottom and the four sides of the middle plate 2 as the upper bottom, the four vertices of the middle plate 2 are respectively in the plate body The center point of 1 is the four coordinates I1 (x0, y0), I2 (x0, -y0), I3 (-x0, -y0) and I4 (-x0, y0) in the X / Y coordinate axis established by the origin point, where the calculation formulas of coordinate points x0 and y0 are respectively:

[0053]

[0054] In the formula, L is the length of the long side of the plate body 1; it is the length of the short side of the plate body 1; ...

Embodiment 2

[0066] An assembly method of a splicable concrete two-way assembly plate, the specific steps are as follows:

[0067] Step 1. Determine the size and service load of the overall panel body 1 panel according to the actual requirements of the project;

[0068] Step 2: Determine the size of the middle plate 2 and the four sets of trapezoidal plates 3 through calculation according to the size of the plate body 1, determine whether reinforcement is required in the plate and the selected installation combination between the plates according to the load used, and the reinforcement is included in the middle plate 2 and four sets of trapezoidal plates 3 pre-embed the first double-layer reinforcement 16, the second double-layer reinforcement 17 or prestressed reinforcement or herringbone truss 11;

[0069] Step 3, making plates according to the size parameters, and then transporting them to the project site for assembly;

[0070] The specific assembly steps are as follows:

[0071] S1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com