Sampling device for chemical laboratory analysis

A sampling device and chemical technology, applied in the direction of sampling devices, etc., can solve the problems of inconvenient cleaning of the feeding port and inconvenient mixing of chemical raw materials in time, and achieve the effects of reducing workload, enhancing uniformity, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

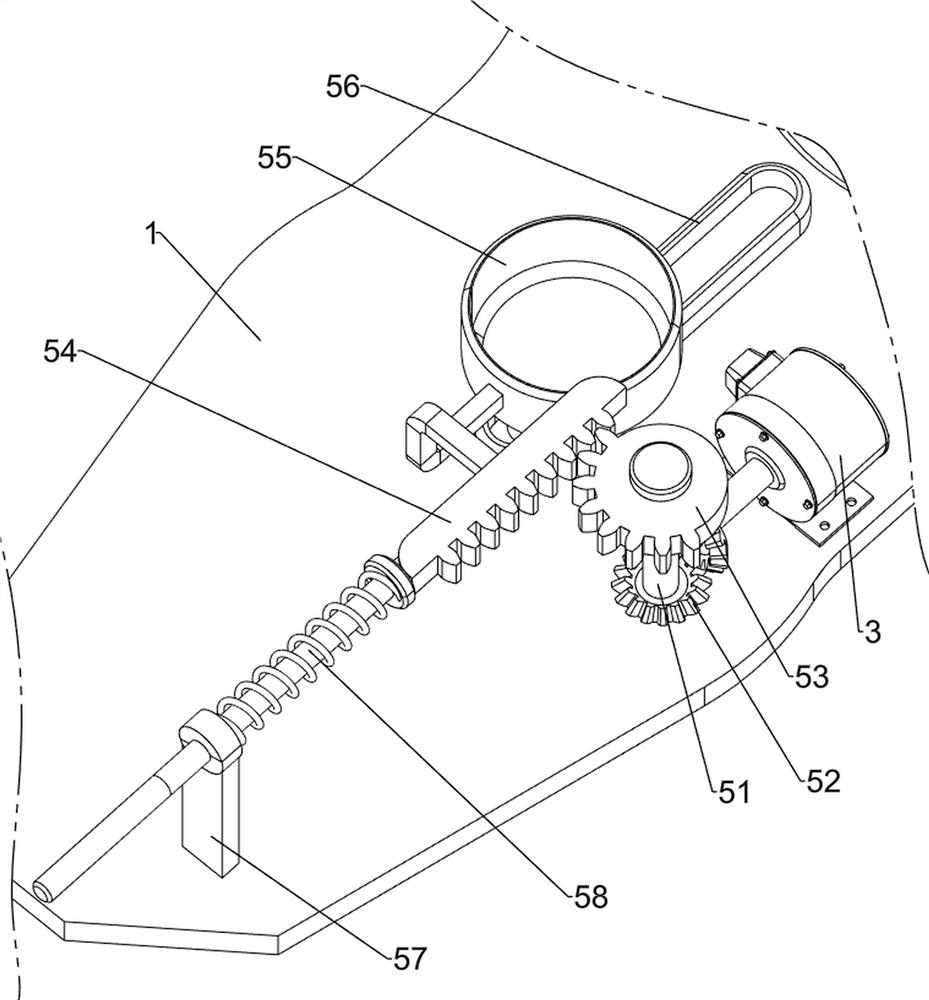

[0028] A kind of sampling device for chemical laboratory analysis, such as figure 1 As shown, it includes a first workbench 1, a second workbench 2, a first motor 3, a blanking mechanism 4 and a sampling mechanism 5, and the upper rear part of the first workbench 1 is provided with a second workbench 2, and the first workbench A first motor 3 is installed in the middle of the right side of the table 1, a feeding mechanism 4 is provided on the top of the second workbench 2, a sampling mechanism 5 is provided on the upper front of the first workbench 1, and the sampling mechanism 5 is connected to the output shaft of the first motor 3. connect.

[0029] When people need to sample chemical raw materials, this sampling device can be used. First, people put the chemical raw materials to be sampled into the feeding mechanism 4, then start the first motor 3, and the output shaft of the first motor 3 rotates to drive the sampling mechanism 5. Move backwards, when the sampling mechani...

Embodiment 2

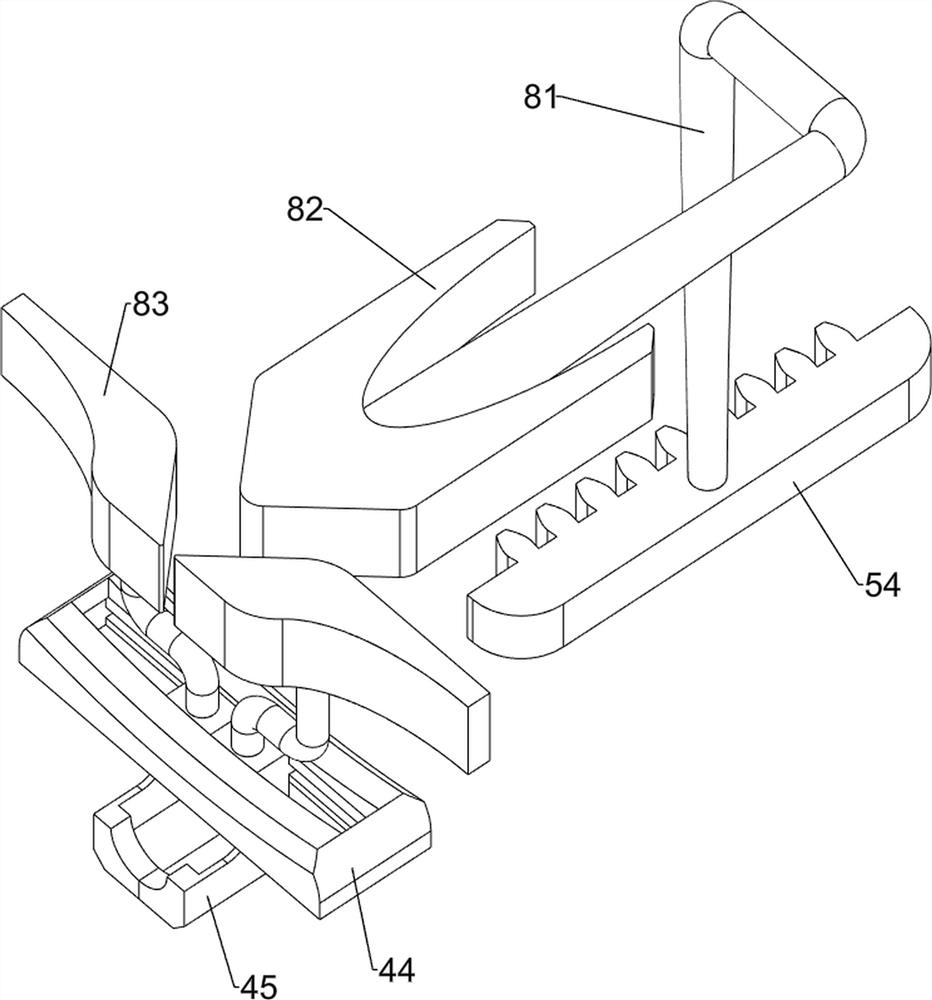

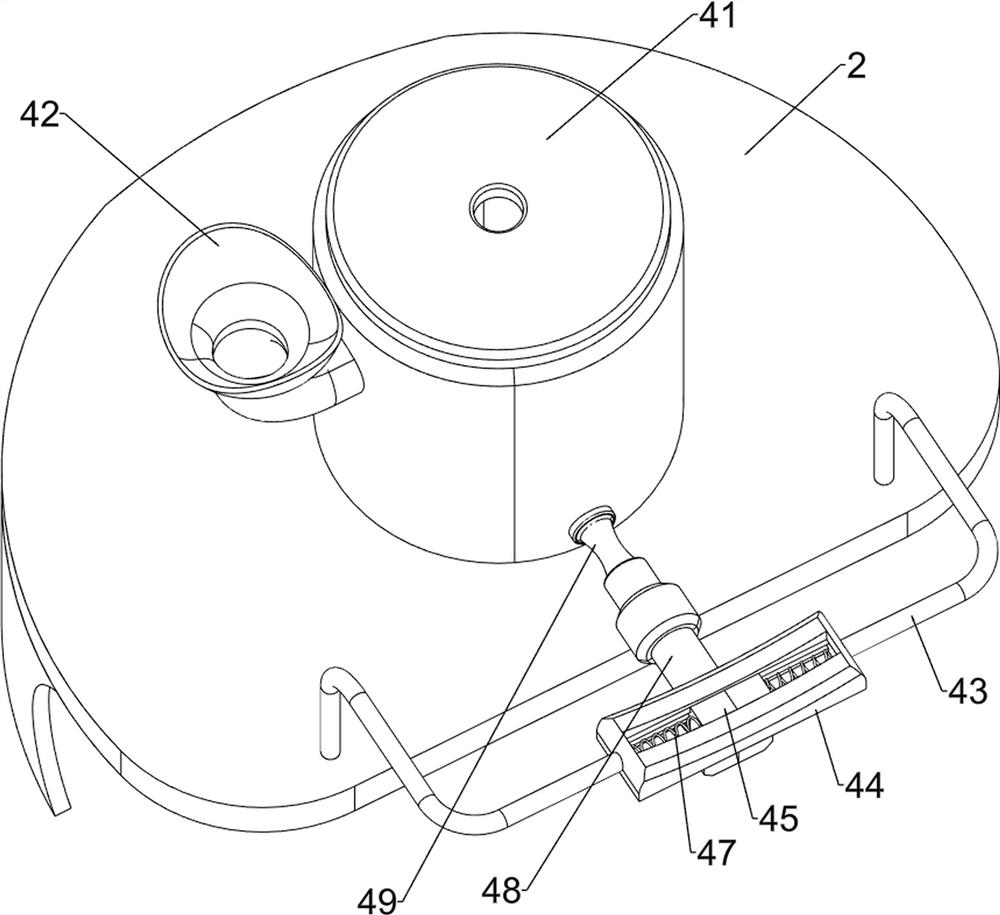

[0031] On the basis of Example 1, such as figure 2 , image 3 and Figure 4 As shown, the blanking mechanism 4 includes a discharge barrel 41, a feed pipe 42, a first fixed column 43, a first slide rail 44, a first baffle plate 45, an absorbent cotton 46, a spring 47, a hard discharge pipe 48 and Discharge hose 49, a discharge barrel 41 is placed on the top of the second workbench 2, a feed pipe 42 is provided on the left side of the upper part of the discharge barrel 41, and a first fixing is provided on the left and right sides of the upper front side of the second workbench 2. Column 43, the first slide rail 44 is arranged between the two first fixed columns 43, the left and right sides of the first slide rail 44 are slidingly provided with the first baffle plate 45, and the two first baffle plates 45 are placed Adsorbent cotton 46 is arranged, and spring 47 is connected between the inner walls on the left and right sides of the first slide rail 44 and the adjacent first...

Embodiment 3

[0036] On the basis of Example 2, such as Figure 5 , Image 6 and Figure 7 As shown, a shaking mechanism 6 is also included. The first workbench 1 and the second workbench 2 are provided with a shaker mechanism 6. The shaker mechanism 6 includes a second bearing column 61, a transmission assembly 62, a second rotating shaft 63, and a placement plate. 64. The third bearing column 65, the bump 66, the shifting block 67, the shaking box 68 and the second telescopic assembly 69, the second bearing column 61 is arranged in the middle of the upper right side of the first workbench 1, and the top right of the second workbench 2 The side is provided with a placement plate 64, the front and rear sides of the top of the placement plate 64 are provided with a third bearing column 65, and a second rotating shaft 63 is rotatably connected between the top of the second bearing column 61 and the top of the two third bearing columns 65. The transmission assembly 62 is connected between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com