Rapid detection method and device for stamping valve plate parts

A technology for detecting devices and parts, applied in measuring devices, optical testing of flaws/defects, material analysis through optical means, etc., can solve problems such as uncertainty and large amount of computation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

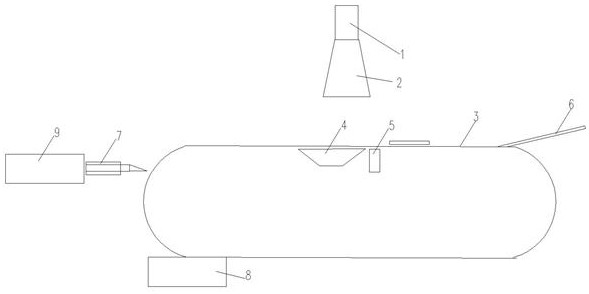

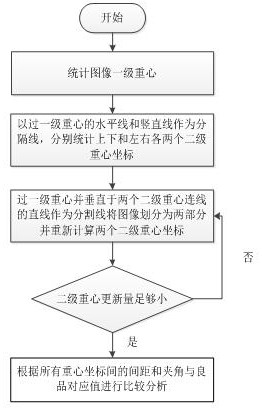

[0020] This embodiment provides a quick detection device for stamping valve parts, including a smart camera 1, a lens 2 is installed under the smart camera 1, the smart camera 1 and the lens 2 are assembled together, and the smart camera 1 Including the image detection algorithm module, the center of gravity process of the image detection algorithm module does not involve floating-point calculations, and each time the last step calculates the center of gravity, only one floating-point calculation is used, which is the key to fast speed. The lens 2 is set above the conveyor belt 3 , the stabilized DC cold light source 4 is arranged below the conveyor belt 3, an inductance senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com