Aerospace engine part flaw detection device convenient to move

A technology of aerospace engines and flaw detection devices, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as instability, small flaw detection range, and height that cannot be adjusted, and achieve the effects of ensuring stability, improving accuracy, and increasing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

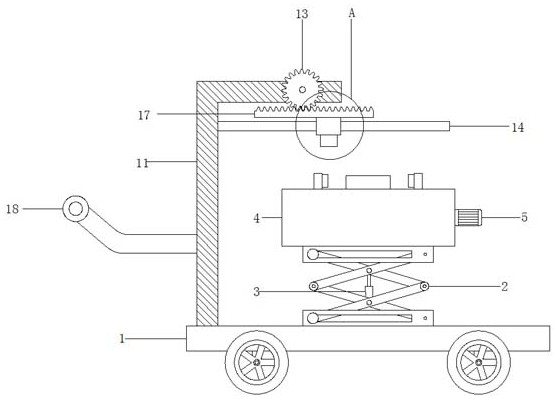

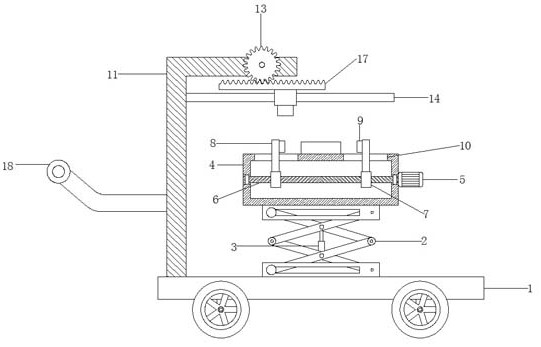

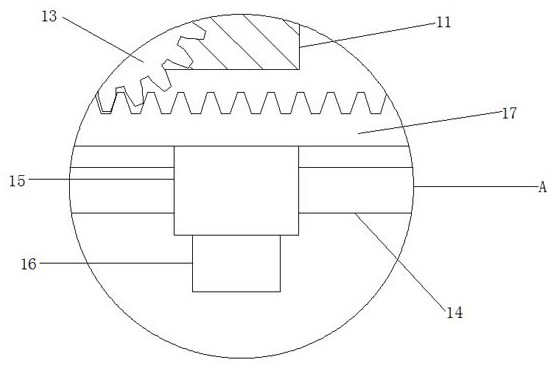

[0021] Embodiment 1, with reference to Figure 1-4 , a flaw detection device for aerospace engine parts that is easy to move, including a base 1 with wheels installed at the four corners of the bottom, a telescopic frame 2 is welded on the top outer wall of the base 1, and a cylinder 3 is installed on the telescopic frame 2, and the top of the telescopic frame 2 An operation box 4 is installed on the outer wall, and a first servo motor 5 is installed on one side of the outer wall of the operation box 4 through bolts, the output shaft of the first servo motor 5 is connected with a two-way screw 6 through a coupling, and the two-way screw 6 is coaxial Two threaded sleeves 7 are sleeved, the top outer walls of the two threaded sleeves 7 are welded with vertical rods 8, and the upper part of the outer wall of the side where the two vertical rods 8 are close to each other is equipped with a non-slip rubber pad 9, and the top of the operation box 4 The inner wall is provided with tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com