Alignment operation process of overlay process in PDMS micro-fluidic chip processing

A microfluidic chip and operation process technology, which is applied in the field of overlay lithography operation process, can solve the problems of increasing the difficulty of alignment operation, and achieve the effect of reducing the difficulty of rough alignment, reducing repeated searching, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] Overlaying is a highly difficult operation in the photolithography process. The overlaying process of microfluidic chips with high precision requirements requires experienced operators to perform, and it takes a whole hour to process and produce microfluidic chips with high overlay accuracy. , need to be repeatedly debugged on the lithography machine.

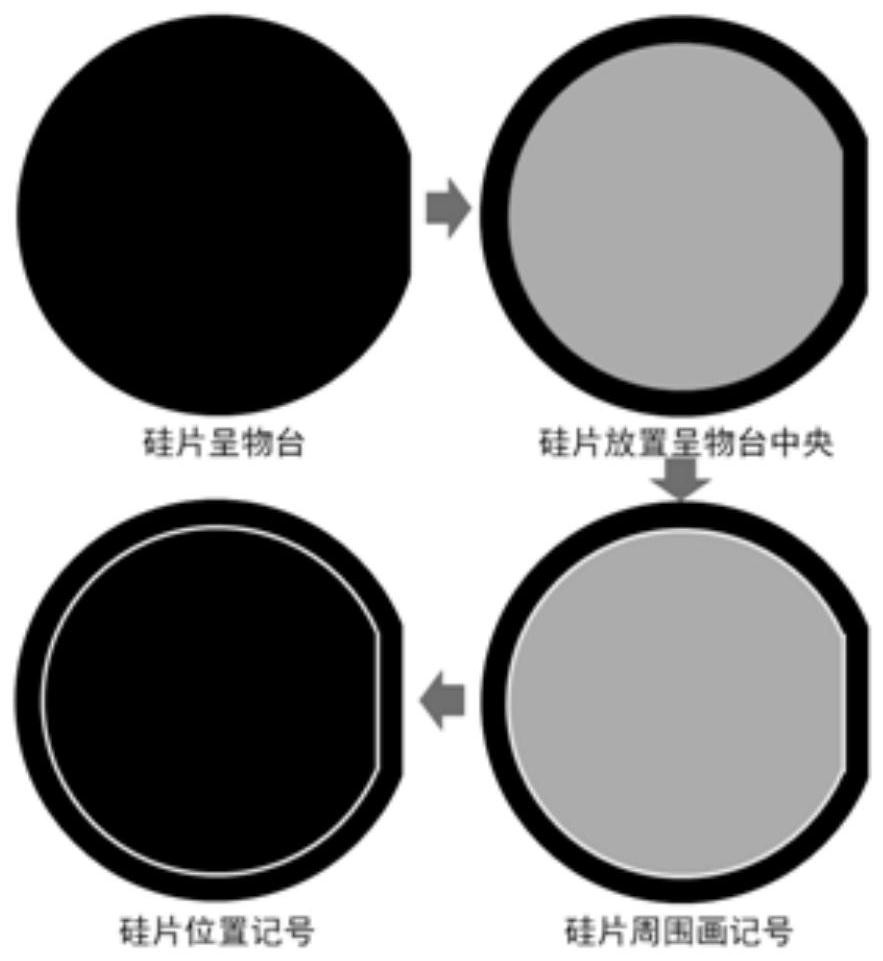

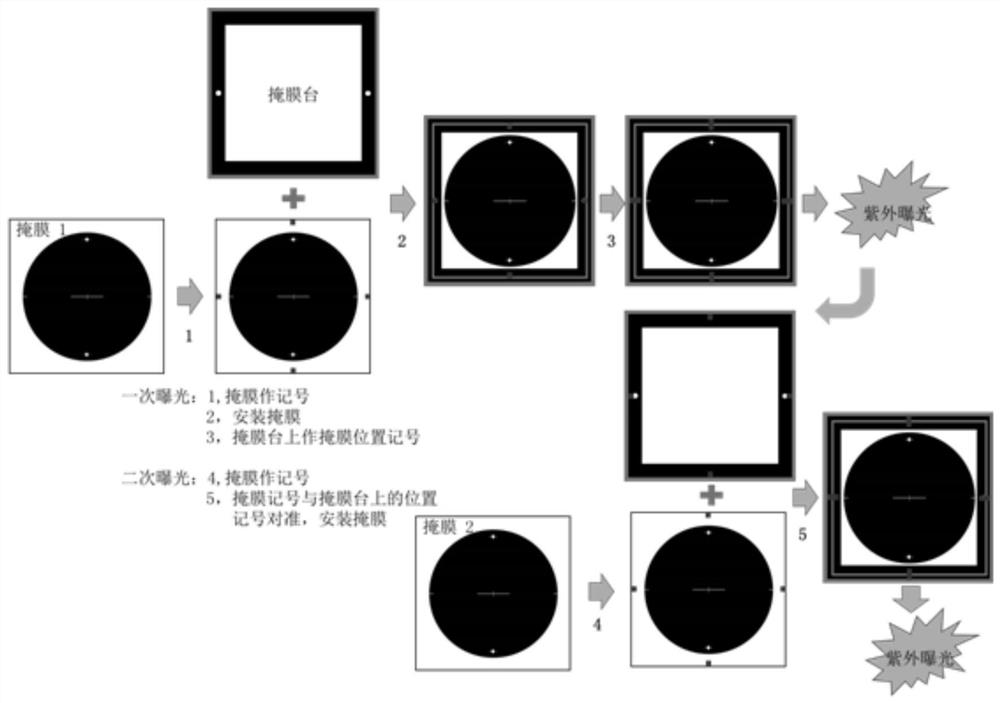

[0024]When designing the microfluidic chip manufacturing and processing mask, the alignment marks of the mask used for the first exposure and the mask for the second exposure are designed at the same position of the mask. In this way, as long as the second exposure during the first exposure and overlay The installation positions of the two masks on the mask table are exactly the same, and the alignment can be achieved by ensuring that the front and rear silicon wafers are also placed in the same position. This design can be called "position overlapping" mask silicon wafer installation, which can The mask alignment mark i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com