Glass energy consumption measuring method and device

A technology of energy consumption measurement and glass, which is applied in special data processing applications, computer-aided design, design optimization/simulation, etc. It can solve the problems of different thermal efficiency of natural gas combustion and affecting the accuracy of glass energy consumption calculation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] The present invention will be further explained below in conjunction with accompanying drawing and specific embodiment:

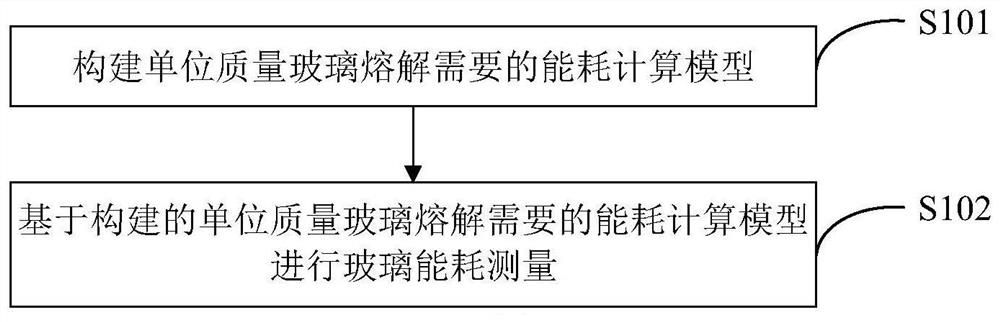

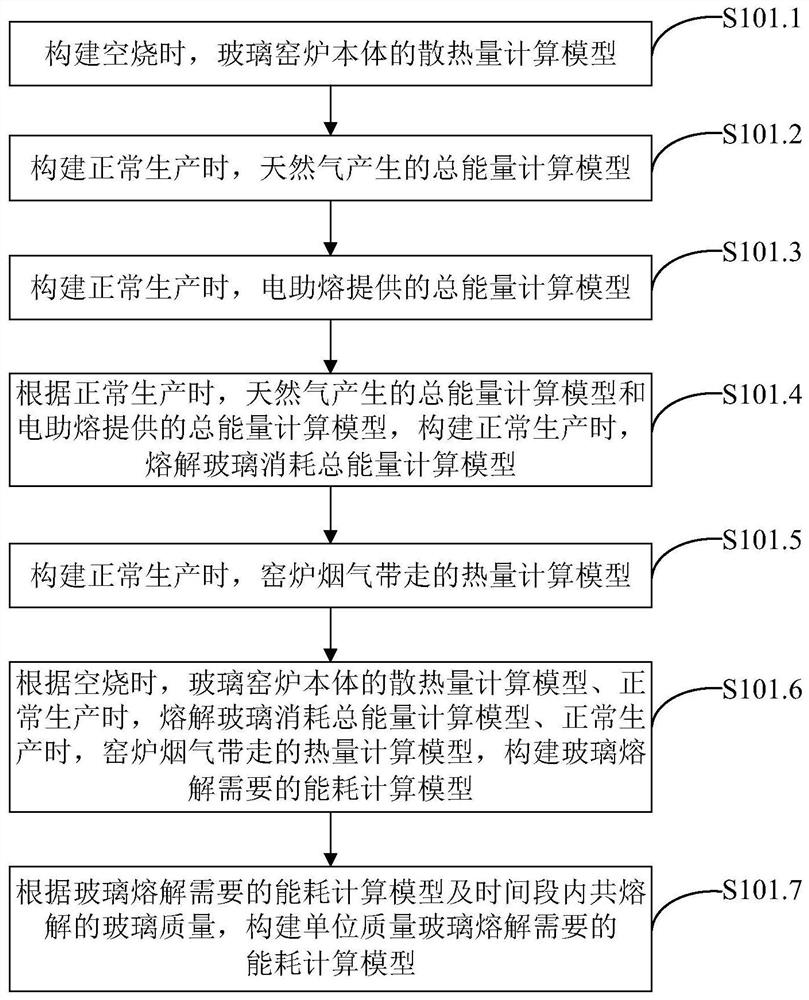

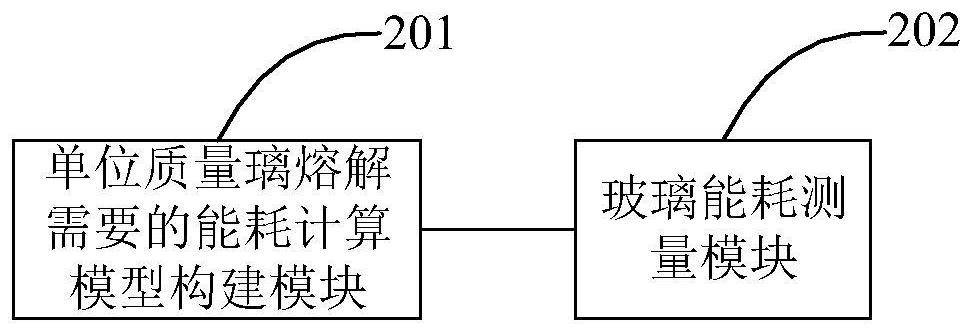

[0081] like figure 1 , figure 2 As shown, a glass energy consumption measurement method, including:

[0082] Step S101: Constructing a calculation model of energy consumption per unit mass of glass melting.

[0083] Specifically, the step S101 includes:

[0084] Step S101.1: Construct the heat dissipation calculation model of the glass furnace body during empty firing;

[0085] Further, during the empty firing, the heat dissipation calculation model of the glass kiln body is:

[0086] Q out =Q gas-out –Q smoke-out ⑤

[0087] in,

[0088] Q gas-out =q×V gas-out ×t ⑥

[0089] Q smoke-out = ρ smoke ×V smoke-out ×t×(t smoke-out –T)×c smoke-out ⑦

[0090] From formulas ⑤, ⑥, ⑦:

[0091] Q out =q×V gas-out ×t–[ρ smoke ×V smoke-out ×t×(t smoke-out –T)×c smoke-out ] ⑧

[0092] where Q out When it is empty firing, the heat dissip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com