Electric arc prevention method and electric arc prevention structure of voltage withstanding machine

A pressure-resistant machine and anti-arc technology, which is applied in the field of rail vehicles, can solve problems such as smoke from the meshing part of the reduction gear of the voltage regulator, increase the workload, and delay the delivery cycle of the equipment, so as to eliminate potential safety hazards, eliminate smoke, The effect of improving the overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

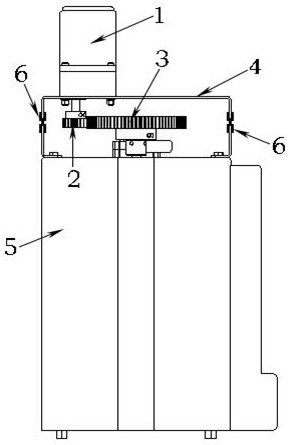

[0023] In order to automatically adjust the output voltage of the voltage-resistant machine, a motor is arranged in the voltage-resistant machine so that the gear of the motor meshes with the gear of the voltage regulator. The gear of the voltage regulator in the pressure-resistant machine is driven to rotate by the motor, so that the voltage in the voltage regulator is automatically adjusted in an electric manner. Such as figure 1 As shown, the motor and the voltage regulator are connected by a fixed frame 4, and the motor casing 1 and the voltage regulator casing 5 are connected to the fixed frame 4 by bolts. The motor is provided with a pinion assembly 2, and the pinion assembly 2 includes a small gear and a small shaft; the voltage regulator is provided with a large gear assembly 3, and the large gear assembly 3 includes a large gear and a large shaft.

[0024] When the fixed frame 4 is an integral metal frame, the small gear assembly 2 on the motor in the pressure-resist...

Embodiment 2

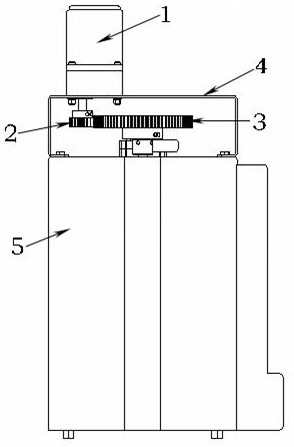

[0028] Such as figure 2 As shown, the difference between the present embodiment and the first embodiment is that the fixing frame 4 is an integral metal frame and has not been cut off. However, at least one of the pinion gear and the small shaft in the pinion gear assembly 2 in this embodiment is made of an insulating material, and the insulating material used is preferably polytetrafluoroethylene, which is plastic king. When the pinion or the small rotating shaft is made of insulating polytetrafluoroethylene, the closed circuit mentioned in the first embodiment is blocked, and no induced current can be formed, so there will be no contact between the pinion and the bull gear. Generate smoke or sparks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com