Sliding rail type telescopic guide plate table

A telescopic guide and sliding rail technology, applied in the attachments, conveyors, shearing devices, etc. of the shearing machine, can solve the problem of poor use effect, and achieve the effect of reducing equipment cost, occupying less space and lowering investment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

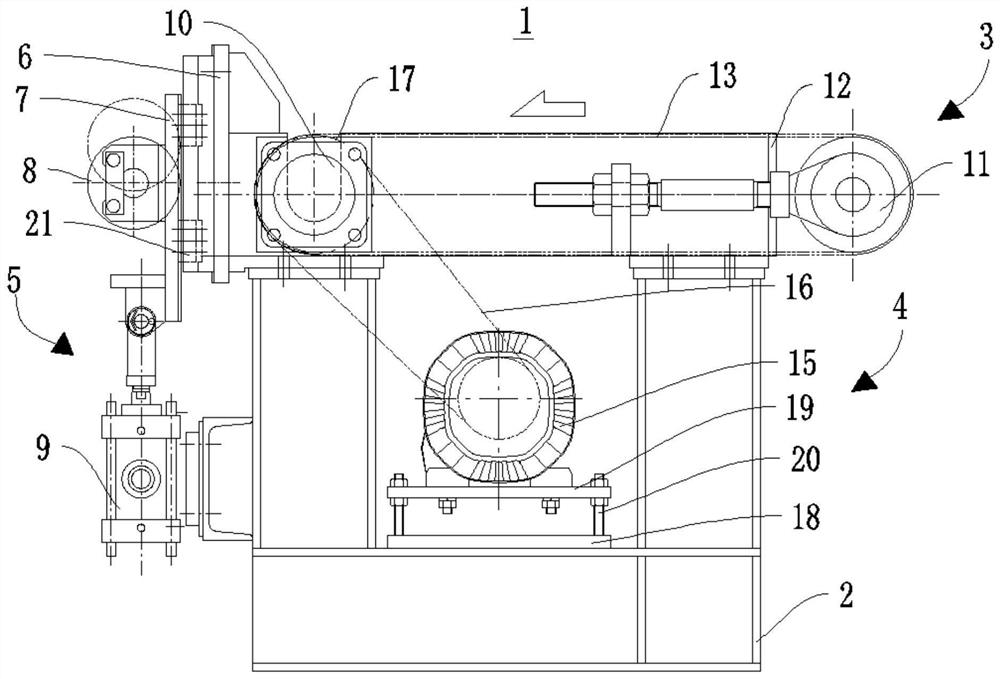

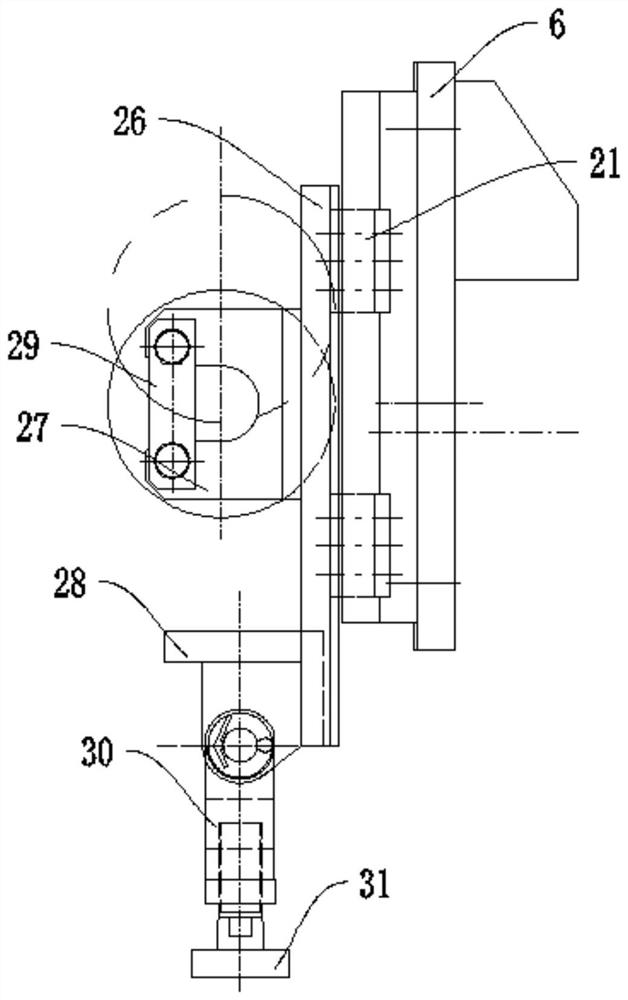

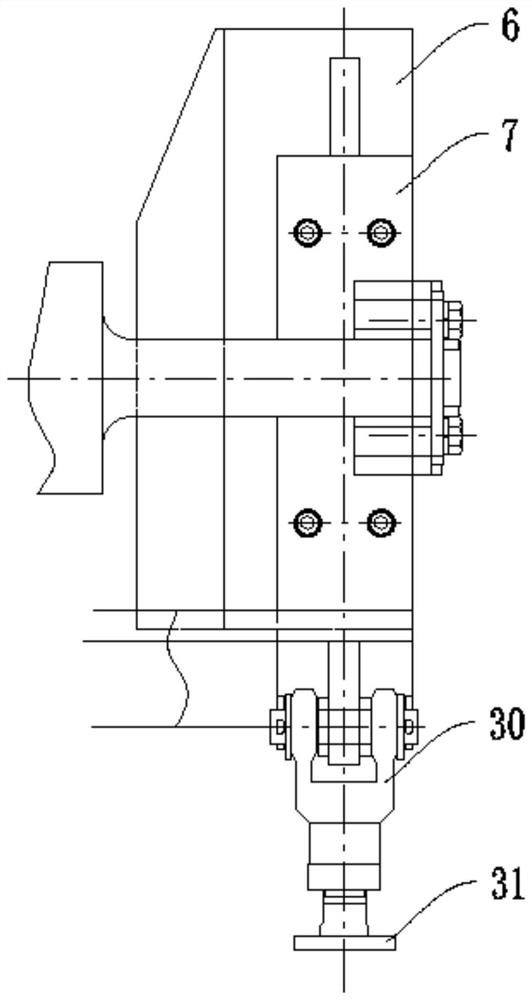

[0032]Please refer tofigure 1 , With referenceFigure 2 to Figure 4, The present application provides a sliding rail type telescopic guide platform 1, including a frame 2, a transmission assembly 3, a driving assembly 4, and a lifting adjustment assembly 5; wherein the transmission assembly 3 is installed on the frame 2 and is used for conveying strip steel; The drive assembly 4 is in transmission connection with the transmission assembly 3, and is used to drive the transmission assembly 3 to move and drive the strip to move on the transmission assembly 3. The lifting adjustment assembly 5 has a roller seat 6, a sliding seat 7, a supporting roller 8 and a driving structure 9. The roller base 6 is fixedly installed on one end of the transmission assembly 3, and one end of the sliding base 7 is connected to the roller base 6 in the height direction of the roller base 6 in a liftable manner. The driving structure 9 is connected to the sliding The bottom of the seat 7 is used to drive th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com