Drilling clamp for bottom inclined oil holes of hydraulic cylinder

A drilling jig and hydraulic cylinder technology, applied in the field of machining, can solve the problems of positioning offset of the drill bit, unsuitable accuracy, and take a long time, and achieve the effects of improving processing efficiency, avoiding positioning offset and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

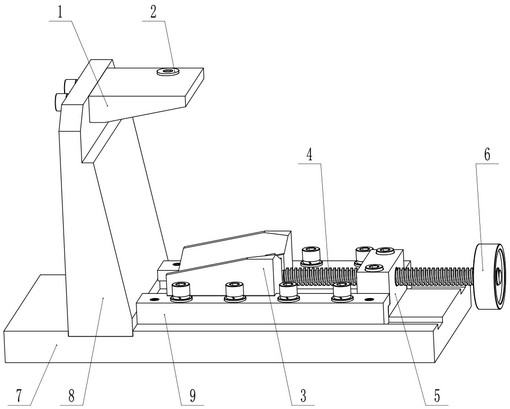

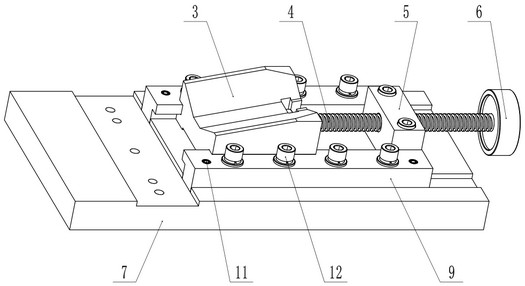

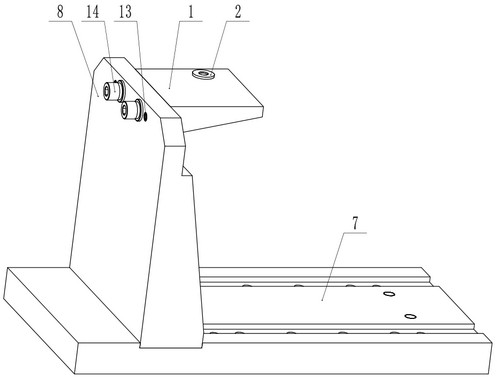

[0028] figure 1 Among them, the present invention includes a guiding and positioning mechanism and a sliding locking mechanism. The guiding and positioning mechanism includes a positioning plate 1. The drill sleeve 2 is installed in the positioning hole of the positioning plate 1 to realize the guidance of the drilling tool. The positioning plate 1 is installed and fixed on the mounting plate. 8, the mounting plate 8 is fixed on the bottom plate 7 to determine the precise position of the oblique oil hole. The right side of the mounting plate 8 is a step structure, and the step structure includes a vertical step part and an inclined step step two. The inclination angle of the inclined surface of the second part of the step is the same as the angle between the oblique oil hole at the bottom of the hydraulic cylinder 10 and the vertical direction. The positioning plate 1 is installed on the right side of the first step, and the lower end surface of the positioning plate 1 is an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com