A rice paper cutting device

A cutting device and rice paper technology, applied in metal processing, agricultural machinery and equipment, energy-saving measures, etc., can solve the problems of low work efficiency, residual unevenness of the cutting rice paper section, etc., and achieve the effect of improving the cutting efficiency of the cutter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

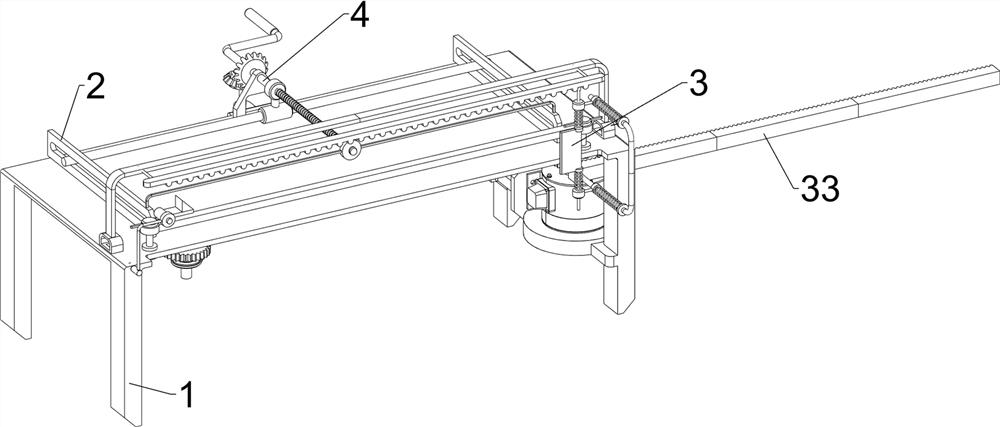

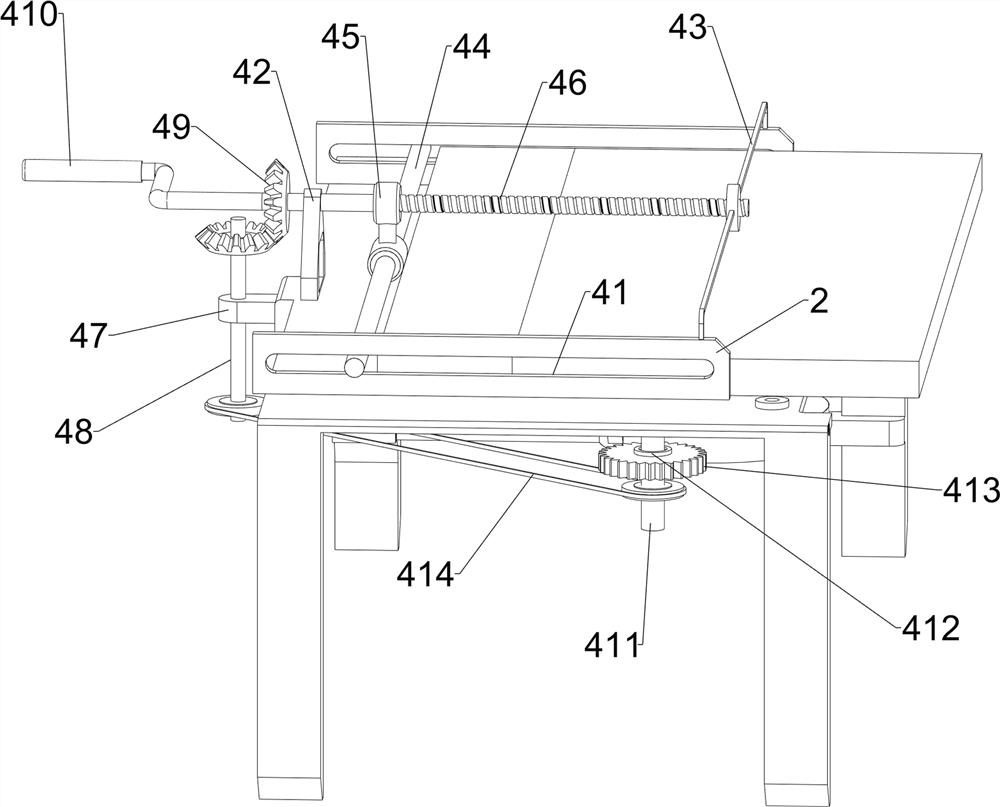

[0022] A rice paper cutting device, such as Figure 1-3 As shown in the figure, it includes a worktable 1, a fixing plate 2, a cutting mechanism 3 and a feeding mechanism 4. The top of the worktable 1 is provided with a left-right symmetrical fixed plate 2, and a cutting mechanism 3 is provided on the rear side of the top of the worktable 1. The top of the worktable 1 is provided with a cutting mechanism 3. A feed mechanism 4 is provided on the front side.

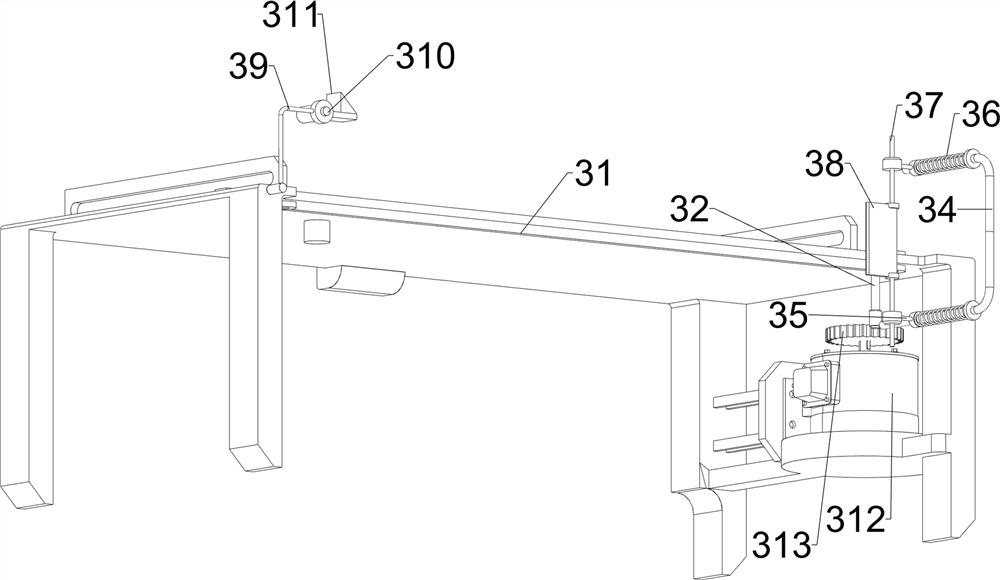

[0023] The cutting mechanism 3 includes a first chute 31, a first sliding rod 32, a rack 33, a first N-shaped rod 34, a first fixing rod 35, a first elastic member 36, a second fixing rod 37, a cutter 38, The third fixed rod 39 , the torsion shaft 310 , the wedge block 311 , the motor 312 and the first circular gear 313 , a first chute 31 is opened on the rear side of the top of the worktable 1 , and a first chute 31 is slidably arranged in the first chute 31 The rod 32, the bottom of the first sliding rod 32 is provided ...

Embodiment 2

[0027] like Figure 4-5 As shown, on the basis of Embodiment 1, a rice paper cutting device also includes a screw rod 5, a pressure rod 6 and a wing nut 7, and a screw rod 5 is arranged symmetrically on the rear side of the top of the workbench 1, and a screw rod 5 is placed between the screw rods 5. A butterfly nut 7 is screwed on the pressure rod 6 and the screw rod 5 , and the butterfly nut 7 cooperates with the screw rod 5 .

[0028] The staff places the rice paper on the workbench 1, places a pressure rod 6 on the rice paper to compress the rice paper, tightens the wing nut 7 to fix the pressure rod 6, and repeats the above operations to achieve equidistant cutting of the rice paper.

[0029] It also includes a second N-shaped rod 8, a guide rod 9, a top block 10 and a second elastic member 11. The rear side of the top of the workbench 1 is provided with a second N-shaped rod 8, and the rear side of the second N-shaped rod 8 is provided with a guide Rod 9, the cutter 38 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com