A clamping device for carbon electrode extruder

A carbon electrode and clamping device technology, which is applied in the direction of presses, material forming presses, friction clamped detachable fasteners, etc., can solve the problem of frequent opening and closing of clamping rings, low production efficiency, and problems with clamping rings. Short service life and other problems, achieve the effect of stable and reliable clamping and disengagement process, improve production efficiency and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

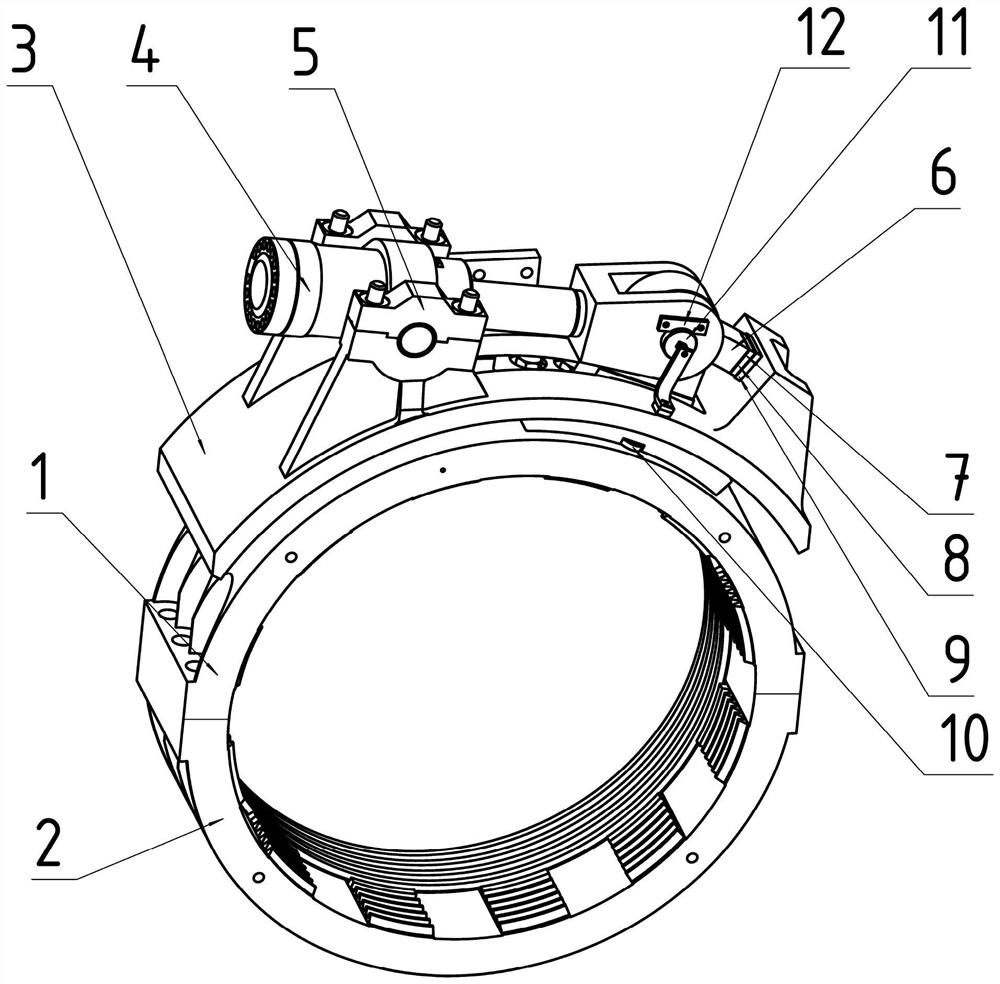

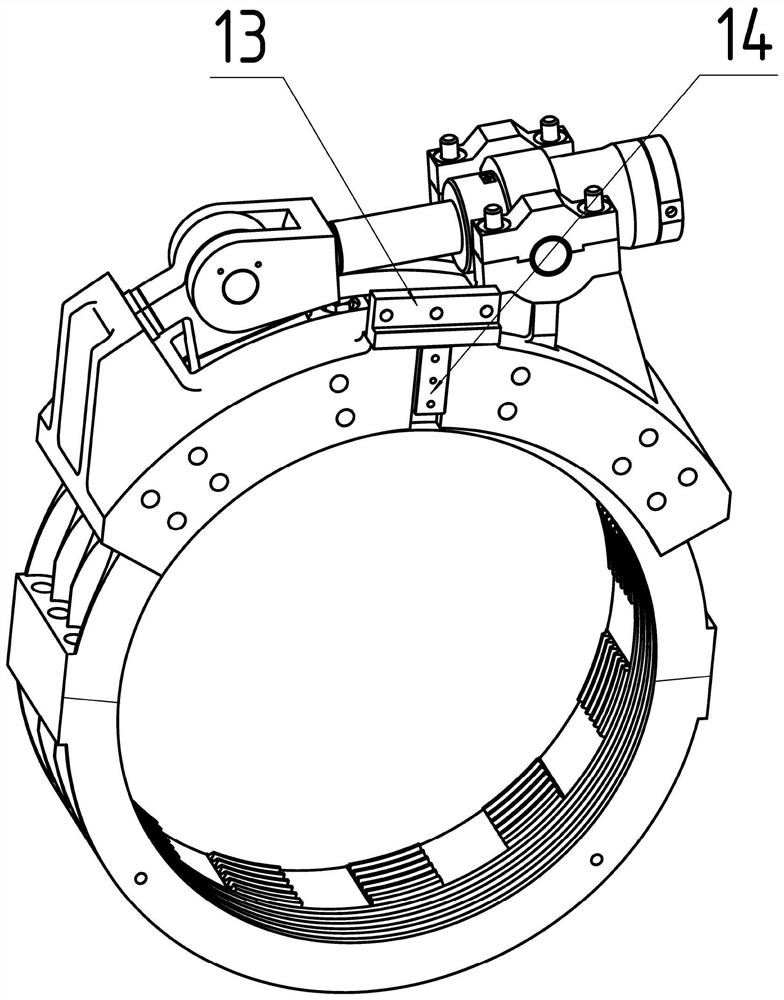

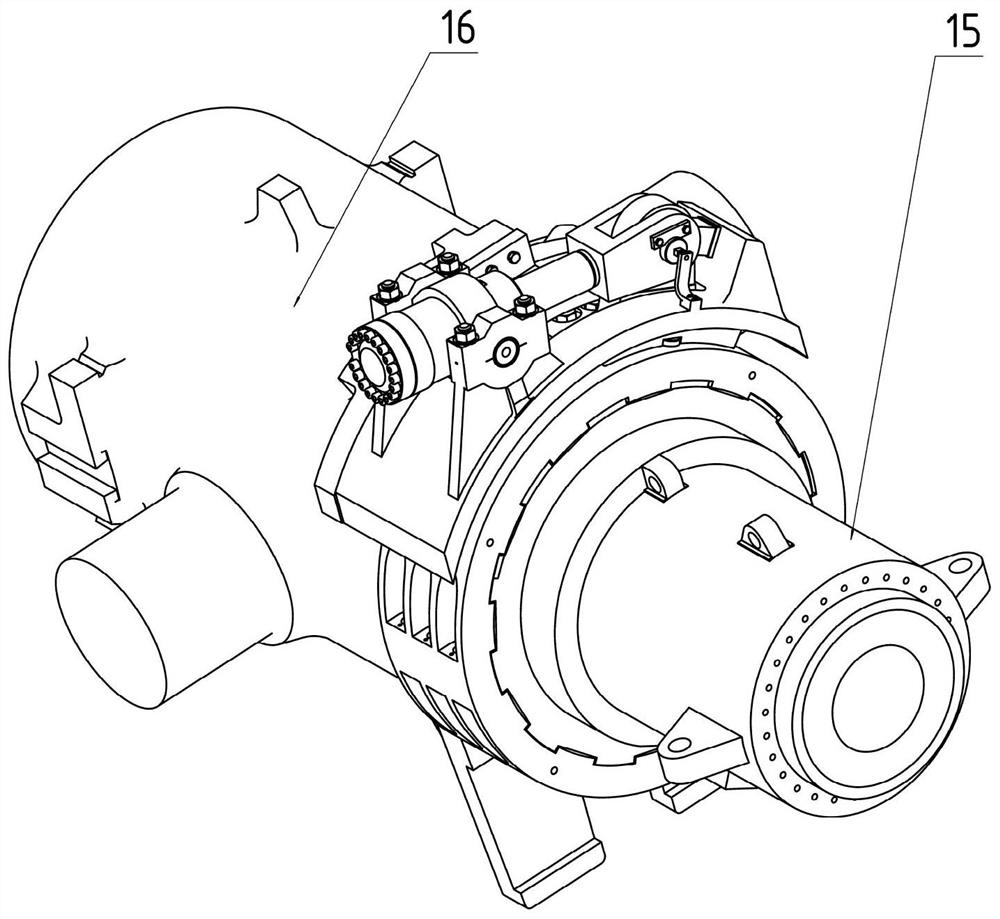

[0023]Clamping device for carbon electrode extruder, including clamping ring and hydraulic clamping mechanism connecting carbon electrode extruder material chamber 16 and mouth 15, clamping ring includes clamping upper ring 1 and clamping lower ring Ring 2, clamping upper ring 1 and clamping lower ring 2 are connected by bolts, and the outer surface of clamping upper ring 1 is provided with positioning grooves. The hydraulic clamping mechanism includes bracket 3, hydraulic clamping cylinder 4, penguin plate 6, pad The block group and the positioning key; the bracket 3 includes an arc bottom plate, a bearing frame and a tail block. The arc plate is an arc plate that matches the outer circle of the clamping upper ring 1. There is a long slot hole in the middle of the arc plate. The side of the arc plate on the side connected to the material chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com