Bag cutting and feeding machine

A feeder and bag cutting technology, which is used in packaging, transportation and packaging, unsealing of packaging objects, etc., can solve the problems of incomplete bag cutting and inaccurate bag grasping position, to simplify the structure and improve the bag cutting effect. , Improve the effect of bag grabbing and dumping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

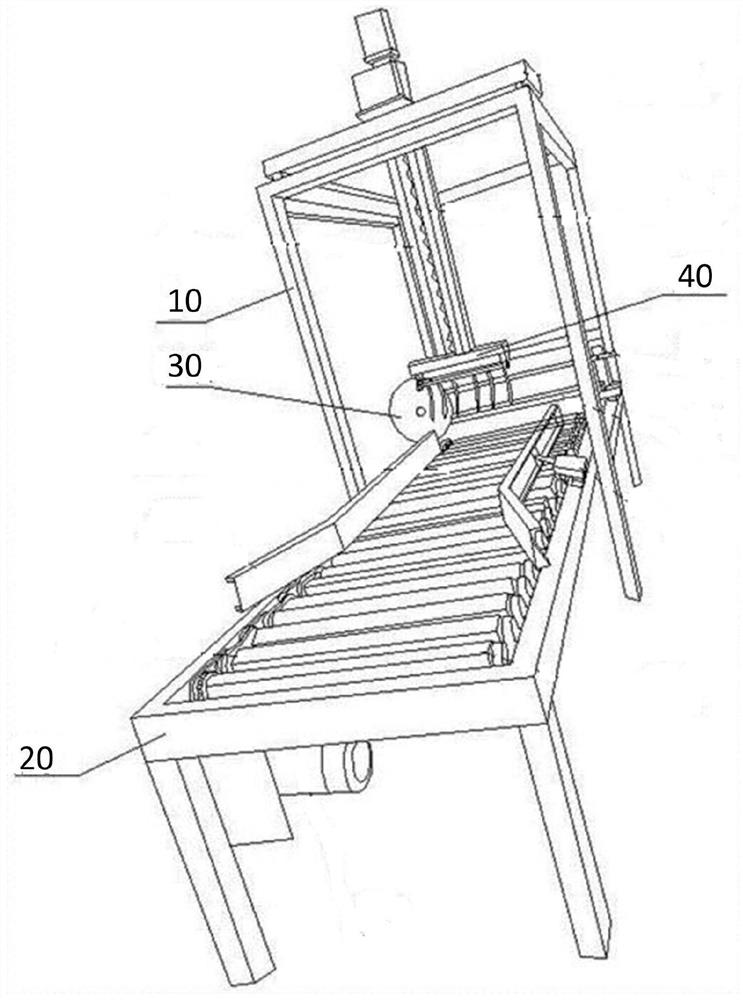

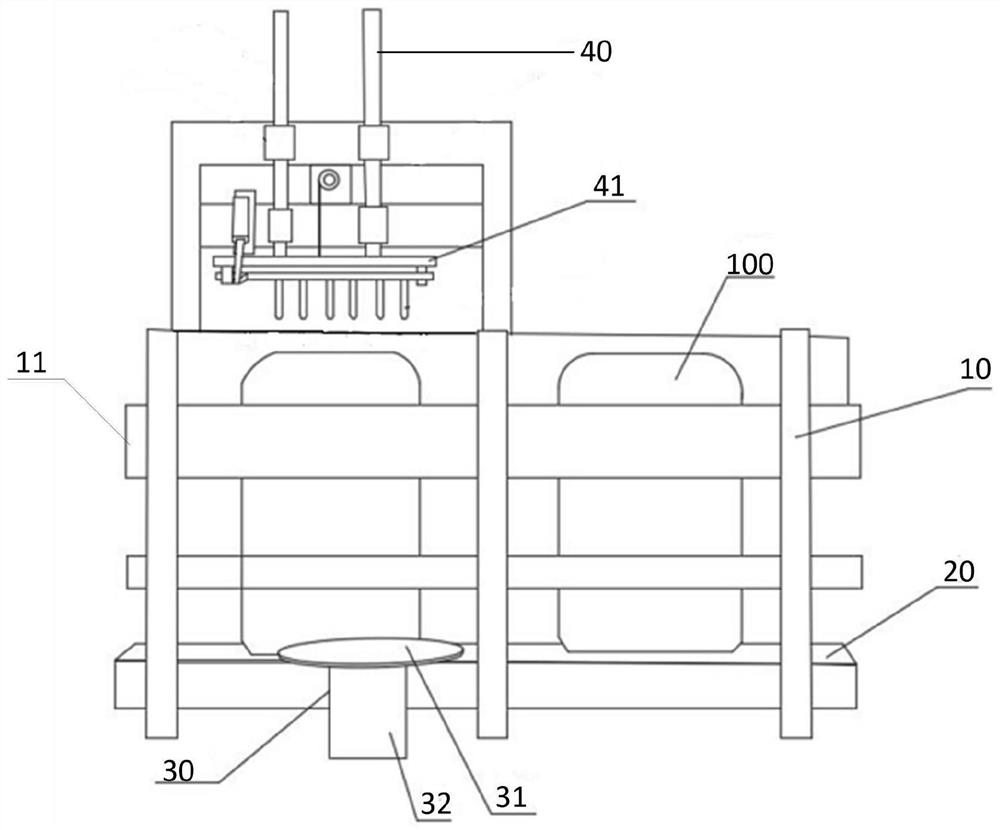

[0037] see figure 2 , Propose the first embodiment of the cutting bag feeding machine of the present invention. The bag-cutting feeder includes a bracket 10 , a conveying mechanism 20 , a bag-cutting mechanism 30 and a bag-grabbing mechanism 40 , and the conveying mechanism 20 , the bag-cutting mechanism 30 and the bag-grabbing mechanism 40 are all installed on the bracket 10 . The conveying mechanism 20 can be a belt conveyor, a roller conveyor, etc. In this embodiment, it is preferably a belt conveyor, so that the material bag 100 standing on the conveying mechanism 20 moves more smoothly. The cutting mechanism 30 includes at least one cutting knife 31, which is arranged above the carrying surface of the conveying mechanism 20 and parallel to the carrying surface. The cutting knife 31 should be slightly higher than the carrying surface of the conveying mechanism 20, and can be set to a height of 0.5-5 cm, 0.5-3 cm, 1-3 cm, 1-2 cm, etc. according to actual needs. It should...

Embodiment 2

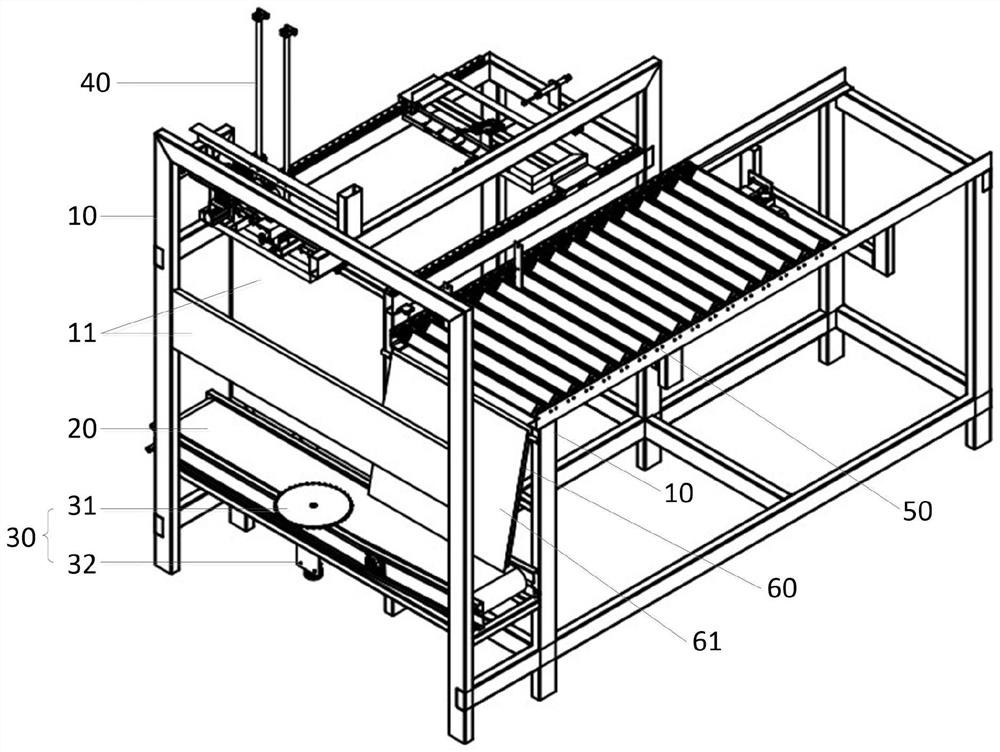

[0045] see image 3 , Figure 4 , propose the second embodiment of the cutting bag feeding machine of the present invention. On the basis of the first embodiment, the cutting bag feeding machine of this embodiment also adds a feeding mechanism 50, which is installed on the bracket 10, and has a material bag feeding port, which is located at the conveying mechanism Above 20, the material bag just falls on the conveying mechanism 20 upright when falling from the material bag delivery port. The feeding mechanism 50 may be a roller conveyor, a belt conveyor, etc., and a roller conveyor is preferred in this embodiment. In this embodiment, the feeding mechanism 50 is arranged horizontally, and is higher than the conveying mechanism 20 as a whole. In some other embodiments, the feeding mechanism 50 can also be arranged obliquely, that is, the feeding opening of the material bag at one end is higher than the feeding opening at the other end. The present invention is not limited th...

Embodiment 3

[0053] see Figure 5 , Figure 6 , propose the third embodiment of the cutting bag feeding machine of the present invention. On the basis of the second embodiment, the cutting bag feeding machine of this embodiment is further provided with a pushing mechanism 70 , which includes a second driving device and a pushing plate 71 . The second driving device is installed on the support 10, the push plate 71 is movably connected with the support 10 and suspended above the conveying mechanism 20 and the bag cutting mechanism 30, the second driving device drives the push plate to move back and forth along the conveying direction 71 of the conveying mechanism , so as to push the material bag under the material bag delivery port of the feeding mechanism to the direction of the bag cutting mechanism. During specific implementation, the slide bar 12 can be fixed on the support 10 on one side of the conveying mechanism 20, and the push plate 71 is slidably connected with the slide bar 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com