Nylon powder coating capable of externally adjusting color and production device

A technology for nylon powder coatings and nylon powders, applied in powder coatings, polyamide coatings, mixers with rotating stirring devices, etc., which can solve problems such as poor tinting strength, insufficient stirring of production equipment, and affecting the use range of nylon powder coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

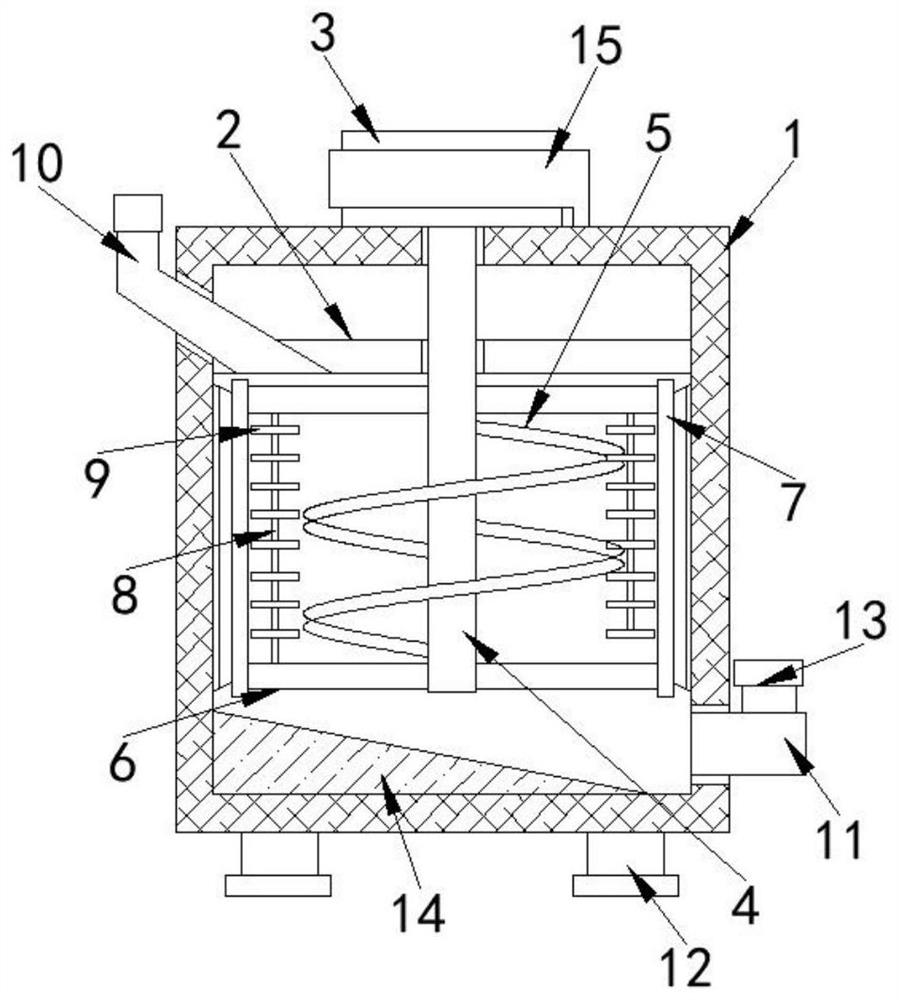

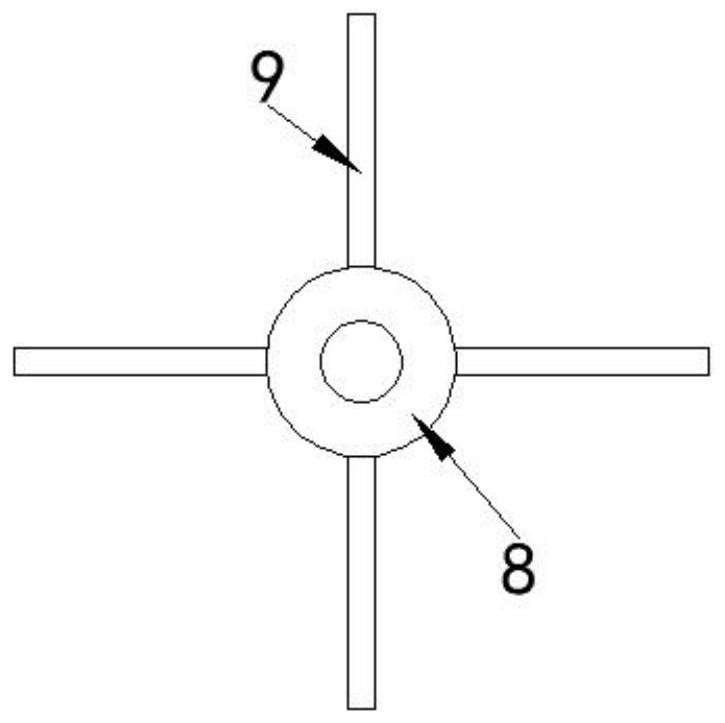

[0023] see Figure 1-2 , an embodiment provided by the present invention: a nylon powder coating capable of external coloring, including nylon powder, pigments and auxiliary agents mixed, 150 parts of nylon powder; 5 parts of pigments; 20 parts of auxiliary agents.

[0024] Furthermore, the nylon powder is PA-1212 resin. The nylon powder is white or natural color.

[0025] Further, nylon powder is white.

[0026] Further, the pigment is an inorganic pigment and the particle size is less than 15 μm.

[0027] Further, the auxiliary agent is one of polyethylene micropowder wax and calcium stearate.

[0028] A nylon powder coating production device capable of external color matching, comprising a stirring box 1, a partition plate 2 is fixedly connected to the top of the stirring box 1, a motor 3 is arranged on the top of the stirring box 1, and a rotating shaft is fixedly connected to the output end of the motor 3. Rod 4, the bottom end of the rotating rod 4 runs through the m...

Embodiment 2

[0034] see Figure 1-2 , An embodiment provided by the present invention: a nylon powder coating capable of external coloring, including nylon powder, pigments and auxiliary agents mixed, 100 parts of nylon powder; 3 parts of pigments; 10 parts of auxiliary agents.

[0035] Furthermore, the nylon powder is PA-1212 resin. The nylon powder is white or natural color.

[0036] Further, nylon powder is white.

[0037] Further, the pigment is an inorganic pigment and the particle size is less than 15 μm.

[0038] Further, the auxiliary agent is one of polyethylene micropowder wax and calcium stearate.

[0039] A nylon powder coating production device capable of external color matching, comprising a stirring box 1, a partition plate 2 is fixedly connected to the top of the stirring box 1, a motor 3 is arranged on the top of the stirring box 1, and a rotating shaft is fixedly connected to the output end of the motor 3. Rod 4, the bottom end of the rotating rod 4 runs through the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com