Liquid metal heat conduction paste and preparation method and application thereof

A technology of liquid metal and thermal paste, which is applied in the direction of chemical instruments and methods, heat exchange materials, etc., can solve the problems of lower thermal conductivity, easy oxidation, difficulty in viscosity control, etc., and achieve the effect of uniform composition and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

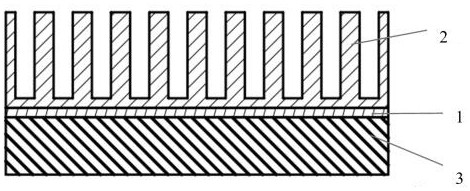

Image

Examples

Embodiment 1

[0028] A liquid metal heat conduction paste and a preparation method thereof, the ingredients include: gallium 60wt.%, indium 24wt.%, tin 15wt.%, zinc 1wt.%. The preparation method is as follows:

[0029] 1) Weigh metal gallium, indium, and tin according to the ratio of raw materials, and put them into the crucible;

[0030] 2) Put the crucible into the vacuum induction furnace, evacuate to 0.5Pa, and raise the temperature to 200°C;

[0031] 3) After gallium, indium and tin are melted, cool to room temperature to obtain gallium indium tin liquid metal;

[0032] 4) Weigh gallium indium tin liquid metal and zinc powder in proportion, put them into a nylon ball mill tank, and add an appropriate amount of nylon balls, the volume ratio of liquid metal to nylon balls is 1:2;

[0033] 5) Set the rotation speed at 300 r / min, and stir for 50 minutes to obtain an all-metal thermal paste.

[0034] The obtained thermal paste has a thermal conductivity of 25 w / (m·K) and a viscosity of 2...

Embodiment 2

[0036] A liquid metal heat conduction paste and a preparation method thereof, the ingredients include: gallium 60wt.%, indium 23wt.%, tin 14wt.%, zinc 2wt.%, silver 1%. The preparation method is as follows:

[0037] 1) Weigh metal gallium, indium, and tin according to the ratio of raw materials, and put them into the crucible;

[0038] 2) Put the crucible into the vacuum induction furnace, evacuate to 0.5Pa, and raise the temperature to 200°C;

[0039] 3) After gallium, indium and tin are melted, cool to room temperature to obtain gallium indium tin liquid metal;

[0040] 4) Weigh gallium indium tin liquid metal and zinc powder in proportion, put them into a nylon ball mill tank, and add an appropriate amount of nylon balls, the volume ratio of liquid metal to nylon balls is 1:2;

[0041] 5) Set the rotation speed at 500 r / min, and stir for 40 minutes to obtain an all-metal thermal paste.

[0042] The obtained thermal paste has a thermal conductivity of 28 w / (m·K) and a vis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com