High-strength low-temperature-toughness wear-resistant steel plate HY550NME and production method thereof

A technology of low temperature toughness and wear-resistant steel plate, applied in the field of steel plate production, can solve the problems of unstable impact toughness at low temperature, poor hardness uniformity of steel plate, long delivery period of imported materials, etc., to eliminate residual stress, reduce internal porosity and segregation, Avoid the effect of excessive grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

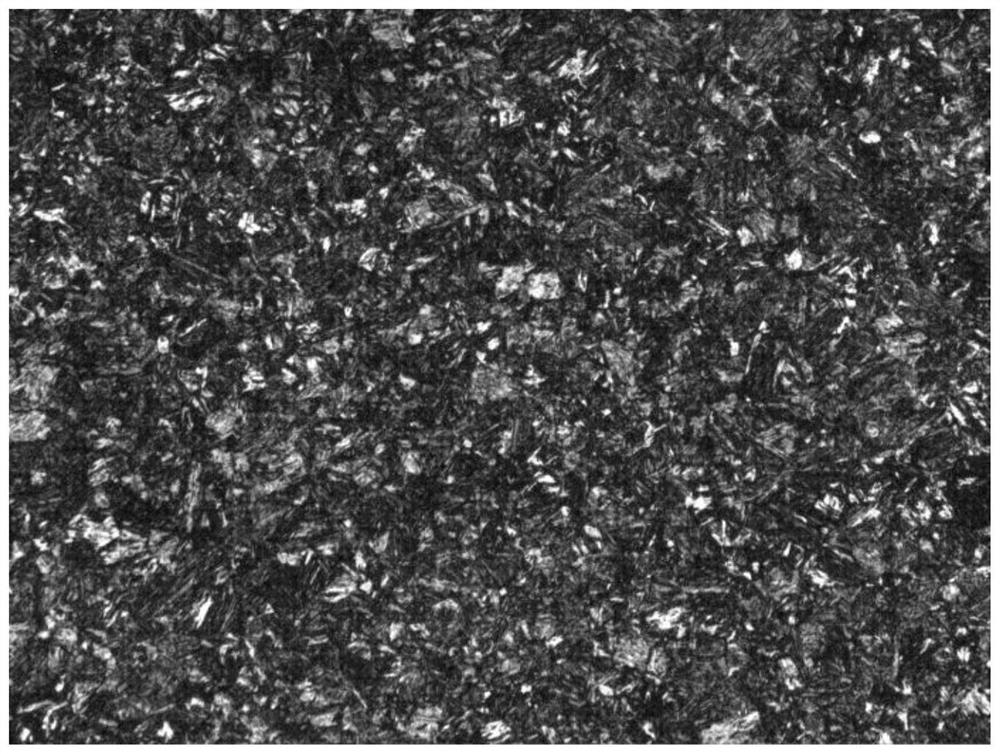

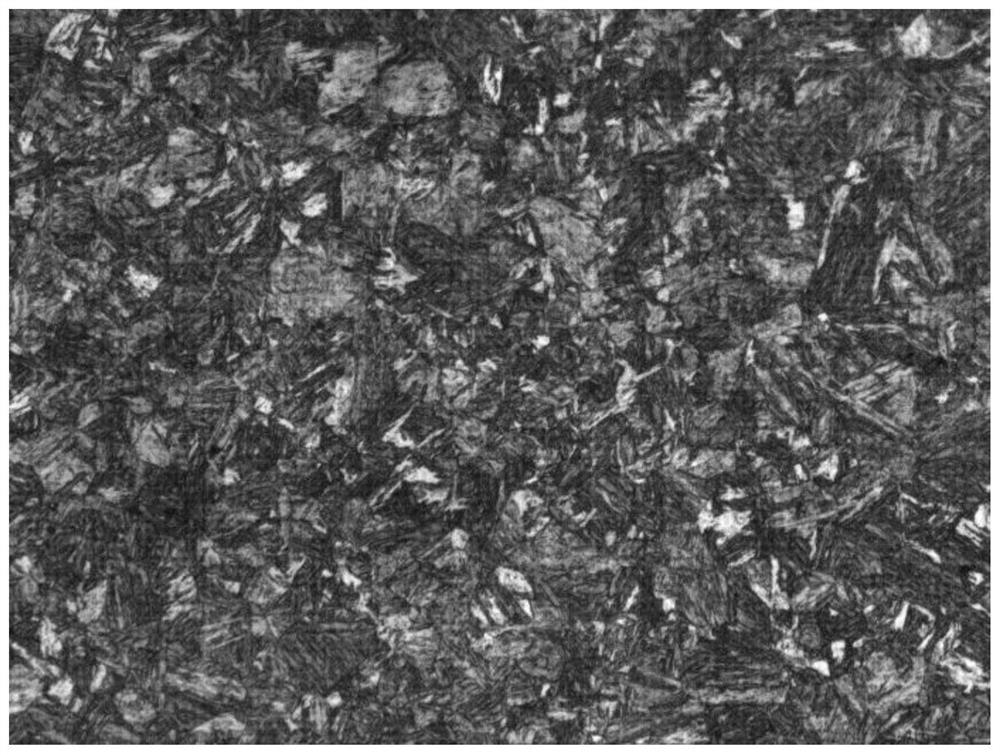

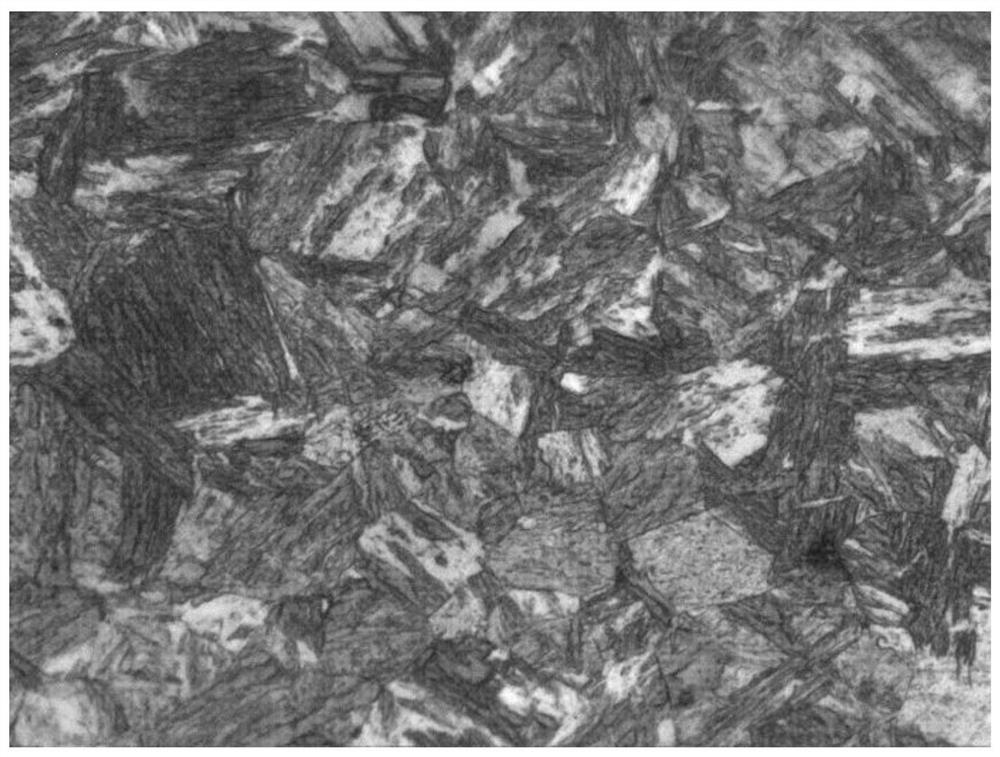

Image

Examples

Embodiment Construction

[0019] The high-strength low-temperature toughness wear-resistant steel plate HY550NME steel plate of the present invention has a thickness of 8-100mm, and contains the following chemical components in mass percentage (unit, wt%): C: 0.22-0.35, Si: 0.10-0.35, Mn: 1.0-1.25 . , Zr: 0.08-0.105, W: 0.25-0.30, others are Fe and residual elements.

[0020] The steps of the production method adopted in the present invention include: KR molten iron pretreatment, 120-ton top-bottom combined blowing converter smelting, LF furnace refining, VD furnace refining, pouring, ingot warming and cooling, heating, rolling, steel plate stacking and slow cooling , Quenching + tempering treatment, finishing, external inspection, flaw detection.

[0021] KR molten iron pretreatment: The slag must be removed before the molten iron arrives at the station to ensure that the thickness of the slag layer on the liquid surface is ≤25mm. After the molten iron is treated by KR, the sulfur content is controll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com