Suspended ceiling mounting structure of prefabricated calcium silicate suspended ceiling embedded bolt

A technology of pre-embedded bolts and installation structures, applied in the direction of ceilings, building components, building structures, etc., can solve the problems of high installation accuracy, easy to break, poor installation effect, etc., to achieve good connection strength, increase stability, and improve work. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

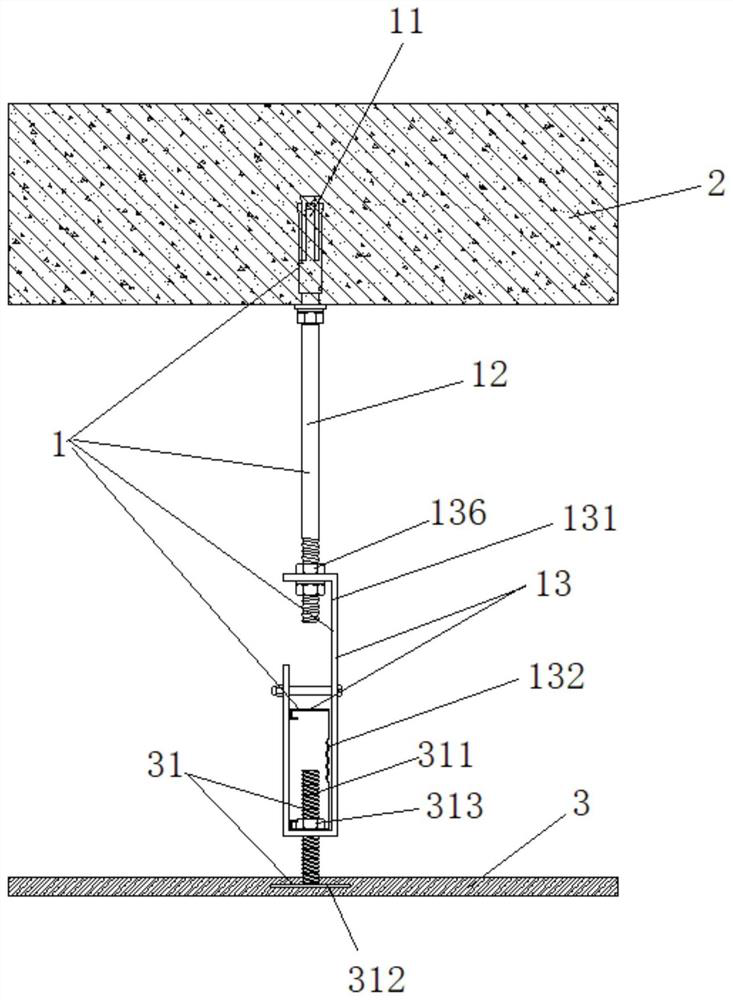

[0031] see figure 1 , the figure shows a ceiling installation structure of pre-embedded bolts for a prefabricated calcium silicate ceiling plate provided by Embodiment 1 of the present invention, which mainly includes: a hoisting assembly 1, which includes expansion tubes 11 arranged sequentially from top to bottom, Suspender 12 and base keel frame 13, the top of expansion pipe 11 is fixedly connected to base wall 2, the top and bottom of suspender 12 are respectively connected to the bottom of expansion pipe 11 and base keel frame 13; calcium silicate ceiling board 3, its surface A connector 31 is pre-embedded, and the connector 31 includes a pre-embedded bolt 311 and a connecting plate 312 , the connecting plate 312 is arranged inside the calcium silicate ceiling board 3 , and the pre-embedded bolt 311 is connected to the base keel frame 13 through an adjusting nut 313 .

[0032] The ceiling installation structure of pre-embedded bolts of an assembled calcium silicate ceilin...

Embodiment 2

[0039] see Figure 1 to Figure 2 , the figure shows a ceiling installation structure of pre-embedded bolts for prefabricated calcium silicate ceiling panels provided by Embodiment 2 of the present invention. This embodiment further makes the following improvements on the basis of the above-mentioned embodiments The technical solution: the connecting plate 312 is parallel to the surface of the calcium silicate ceiling board 3; the embedded bolt 311 is perpendicular to the surface of the calcium silicate ceiling board 3. Through the setting of the above structure, it is convenient for leveling, can ensure the installation accuracy, and improve the installation quality.

Embodiment 3

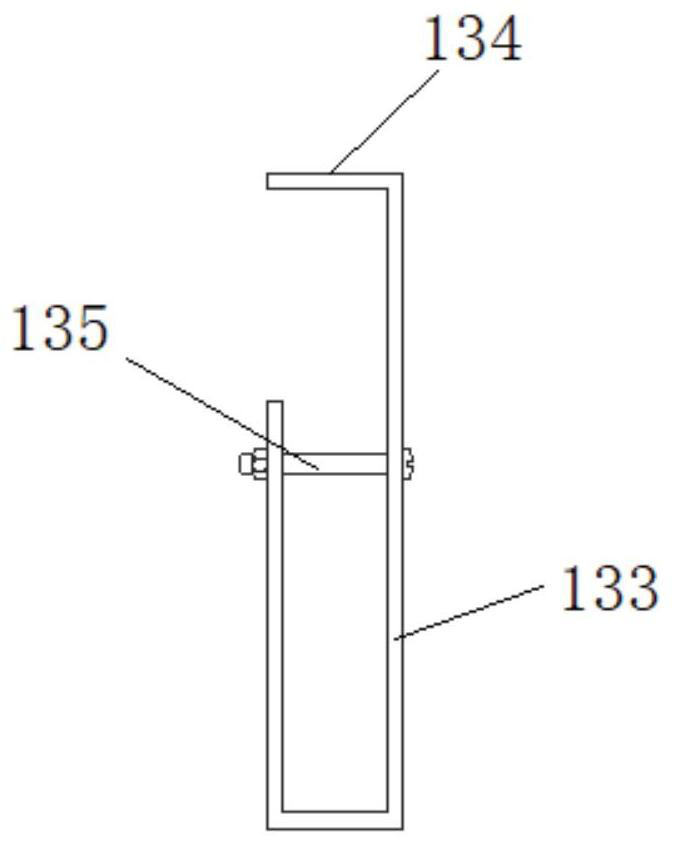

[0041] see figure 1 , the figure shows a ceiling installation structure of pre-embedded bolts for prefabricated calcium silicate ceiling boards provided by Embodiment 3 of the present invention. This embodiment further makes the following improvements on the basis of the above-mentioned embodiments technical solution: the basic keel frame 13 includes a hook 131 and a keel 132, and the hook 131 is sleeved on the outside of the keel 132; Tighten the connection. Through the setting of the above structure, it is convenient to connect and adjust the connection position, the installation is quick, the construction efficiency is improved, and the connection force is good at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com