Indoor micro differential pressure sensor sampling mounting head

A micro differential pressure sensor and sampling tube technology, which is used in sampling devices, pressure difference measurement between multiple valves, sampling, etc. problem, to achieve the effect of enhancing sampling stability, improving measurement accuracy, and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

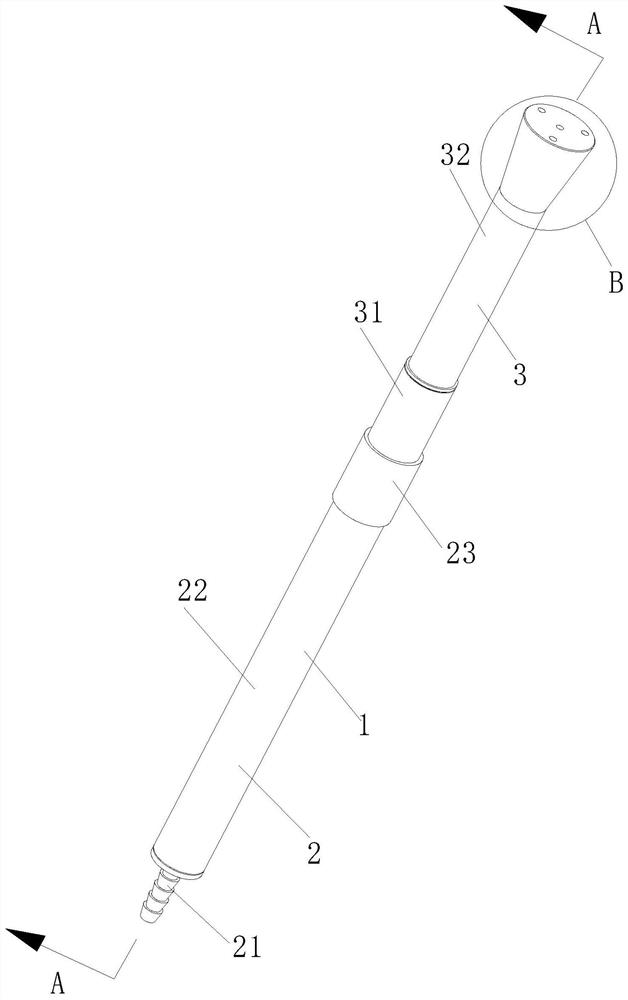

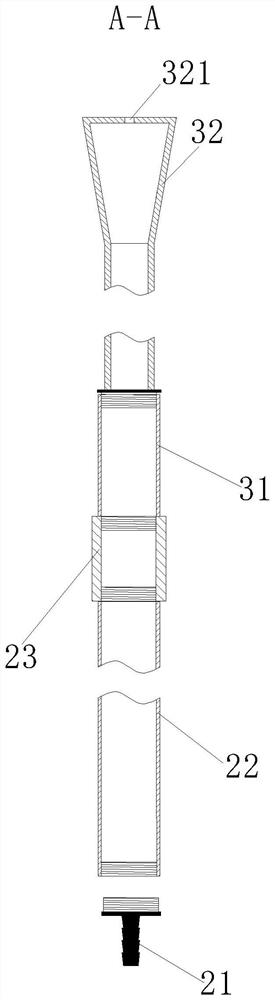

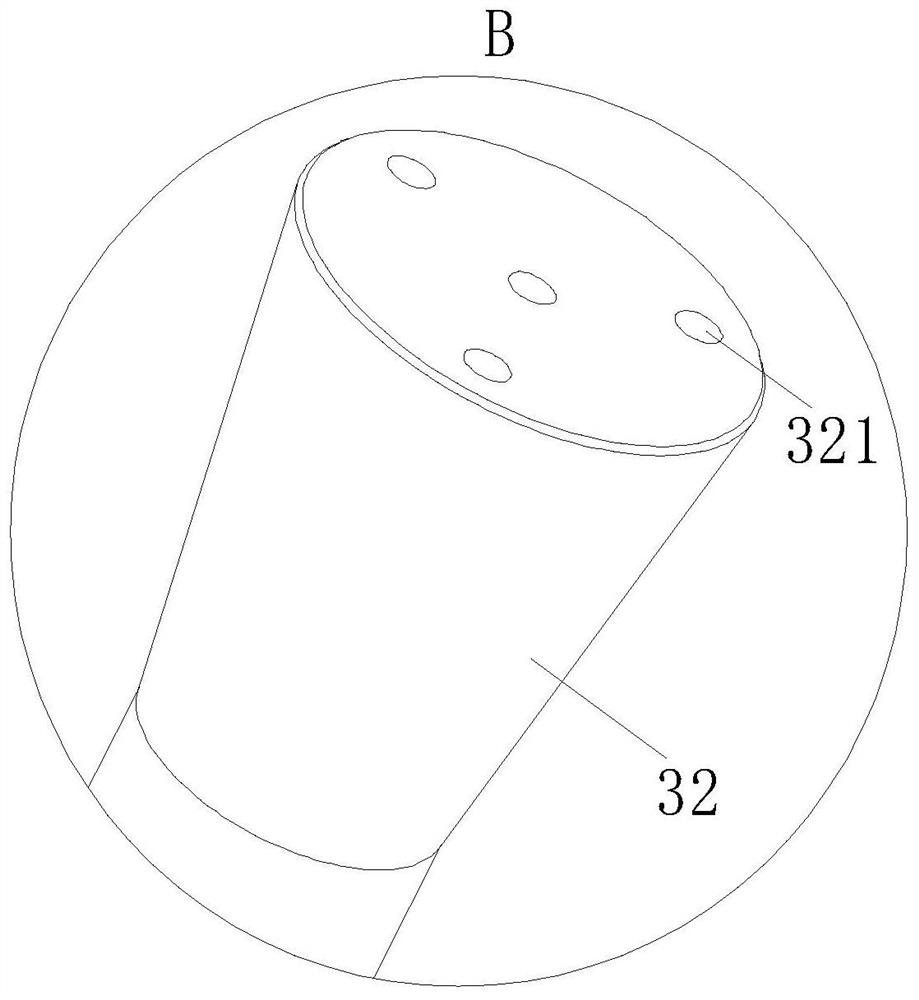

[0022] As a specific embodiment of the present invention, the conduction part 2 includes a hexagonal pagoda joint 21, an extension pipe 22 and a No. 1 adapter 23; the hexagonal pagoda joint 21 communicates with the hose on the external micro-pressure differential sensor, and the hexagonal pagoda The joint 21 is threadedly connected to the extension pipe 22, and the hexagonal pagoda joint 21 can be selected with an internal thread with a nominal diameter of 15MM; the extension pipe 22 is threadedly connected to the No. A double-headed outer thread pipe with a diameter of 20MM, and an extension tube 22 is selected according to the installation length of the body 1; the No. 1 adapter 23 is threaded to connect the collection part 3, and the No. 1 adapter 23 can be selected with a nominal diameter of 20MM with a length of 35mm The double-headed inner wire pipeline of the No. 1 adapter 23 is more suitable for the thickness of the existing ceiling, which is convenient for the fixing o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com