Rock macroscopic fracture toughness calculation method based on nanoindentation technology

A nano-indentation and fracture toughness technology, applied in computing, computer parts, design optimization/simulation, etc., can solve problems such as inability to meet, discrete rock data, and difficulty in complete rock blocks, achieving less samples and lower costs. The effect of low cost and low requirements on specimen shape and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solutions of the present invention will be further described below in conjunction with specific examples.

[0049] A method for testing the macroscopic fracture toughness of rock based on nanoindentation technology, specifically comprising the following steps:

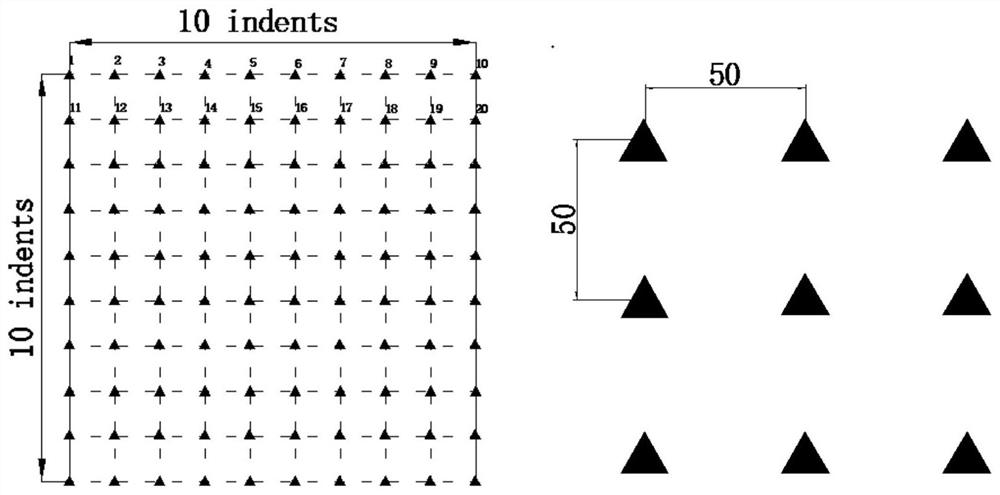

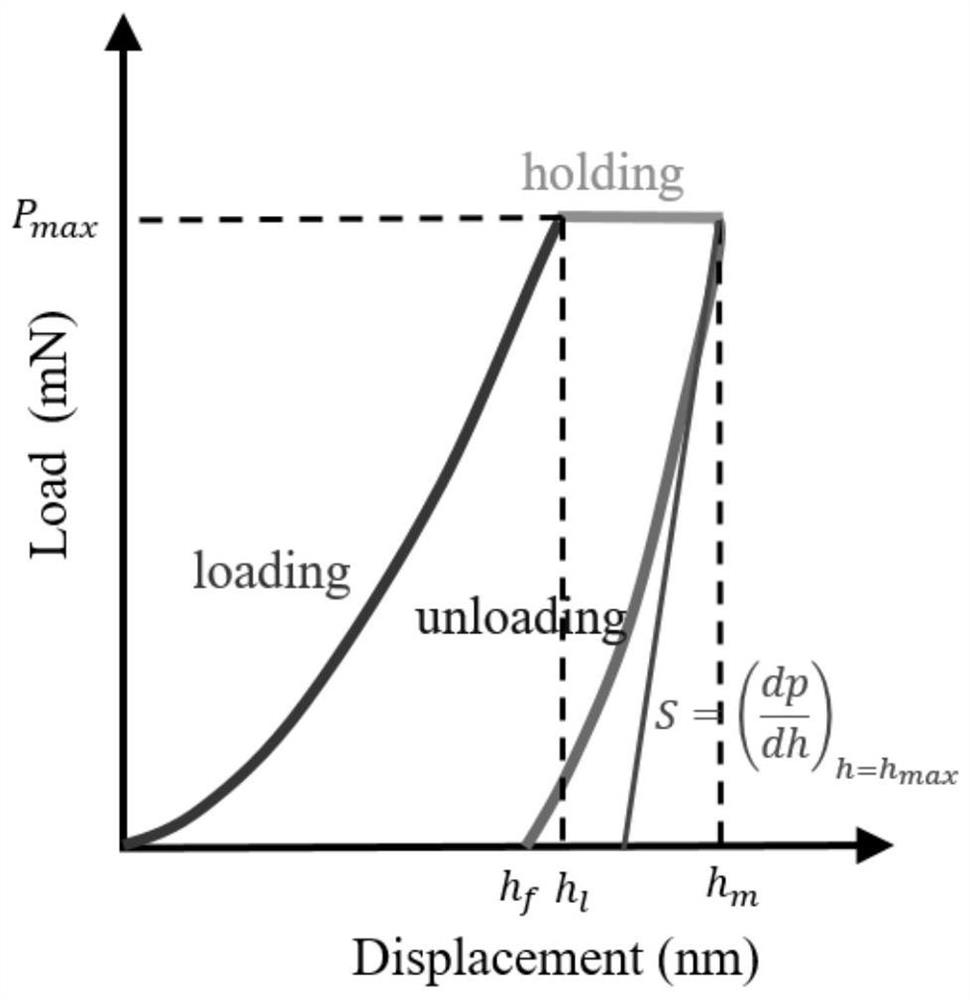

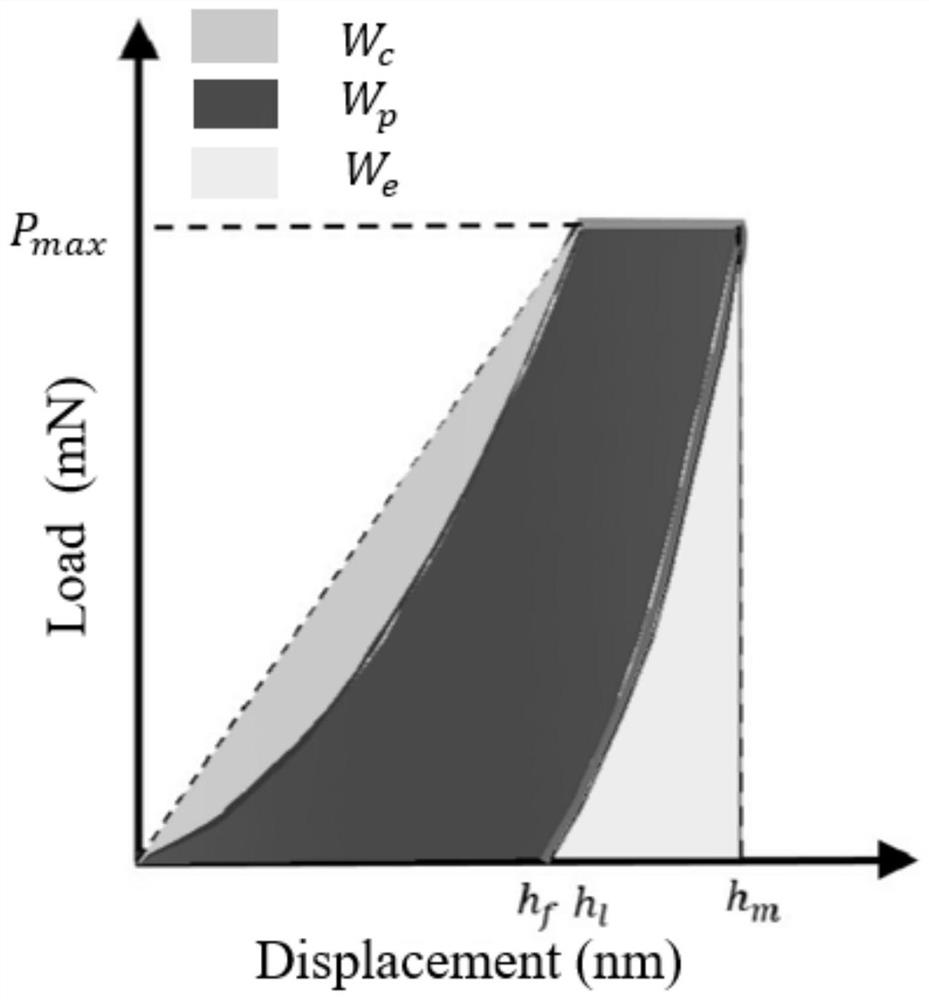

[0050](1) Combining the dot matrix method with nano-indentation technology to obtain the P-h curve of each test point inside the rock material, according to the P-h curve, use the O-P theory to calculate the micro-mechanical parameters (elastic modulus, stiffness and hardness, etc.) of the test point. The schematic diagram of the dot matrix method is as follows figure 1 As shown, the typical P-h curve obtained by the nanoindentation method is as follows figure 2 shown.

[0051] The basic micromechanical parameters (elastic modulus E, hardness H and stiffness S) of each test point are calculated according to formula (1):

[0052]

[0053] Where: P max is the maximum load at the indentation; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com