System and method for detecting geometrical parameters of different components of tire section

A technology of geometric parameters and tires, applied in the field of tire industry, can solve the problems of lack of testing standards, unfavorable tire internal structure expansion design, etc., achieve the effect of standardizing the testing process, reducing repeated operations, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

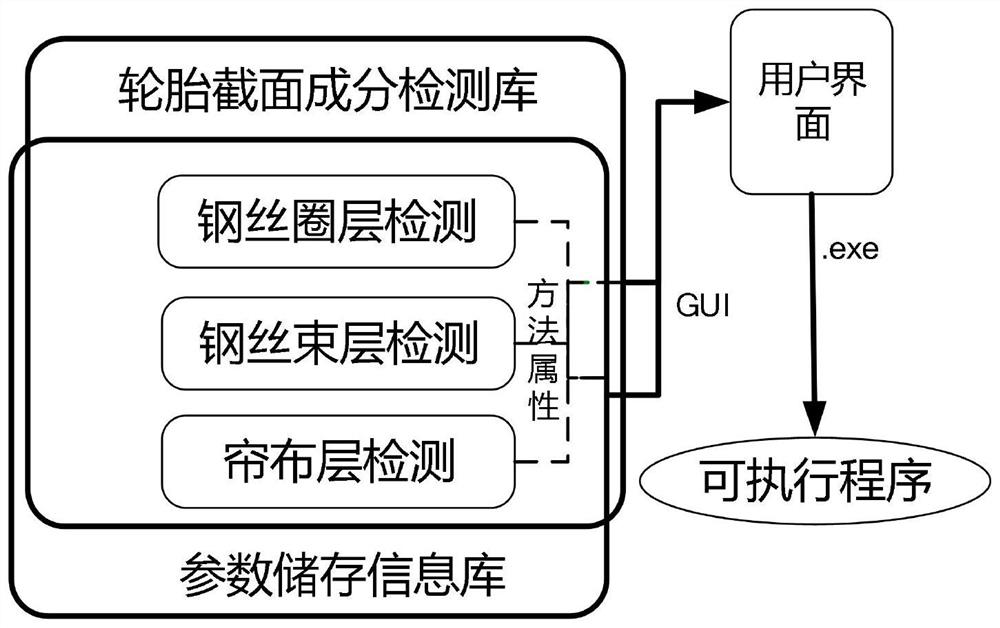

[0068] In this embodiment, the component detection class formed by the packaging of each detection unit includes the fusion of digital information and image information of tire cross-sectional components. The communication between these encapsulated component detection classes is carried out by setting the properties of each detection method. The main interface of the system is designed through MATLAB-GUI, including menu bar options, image display interface, operation buttons, etc., and in matlab. Use the mbuild–setup command to configure the compiler through Visual Studio, call the configured compiler and use the deploytool tool to generate an independent executable program, and complete the instantiation expression of the tire cross-sectional composition analysis. The overall structure diagram of the specific system modular design is as follows: figure 1 shown.

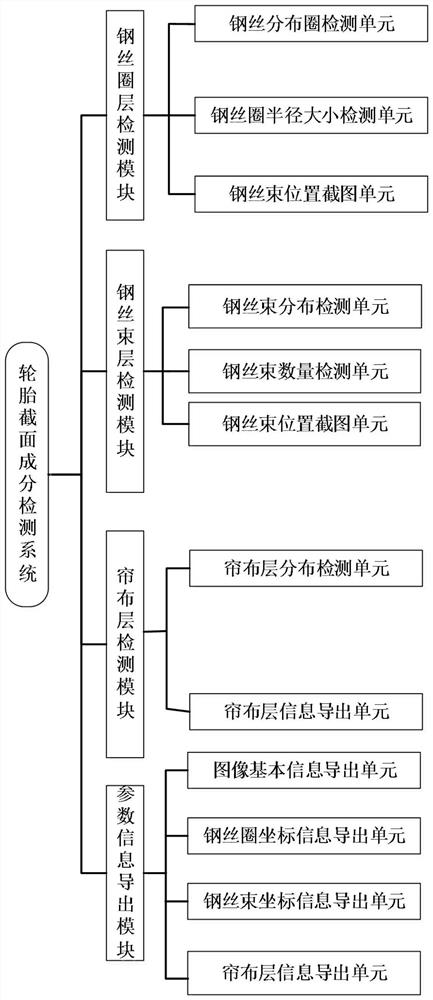

[0069] In this embodiment, a structural diagram of a detection system for the geometric parameters of different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com