Ingot mold molten metal boundary positioning method integrating template matching and symmetric straight line segmentation

A metal solution and symmetrical straight line technology, which is applied in image analysis, image data processing, instruments, etc., to achieve the effects of short calculation time, good detection effect and strong real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

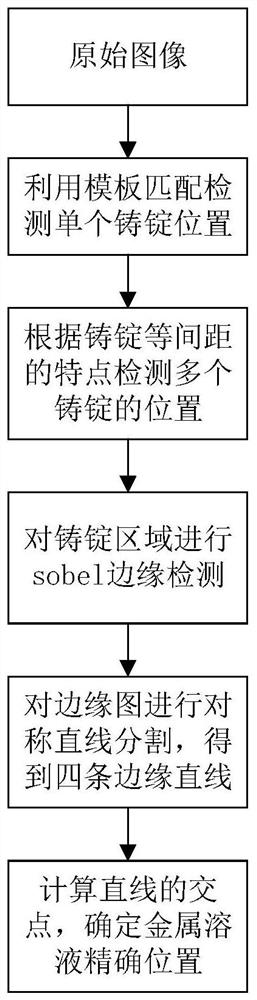

[0036] The following will be combined with Figure 1-8 To illustrate the best implementation mode of the present invention, a method for locating the molten metal boundary of an ingot mold combined with template matching and symmetric linear segmentation implemented according to the present invention is as follows, but is not limited to the following examples.

[0037] Such as figure 1Shown is an overall flow chart of a method for locating the molten metal boundary of an ingot mold combining template matching and symmetric linear segmentation according to the present invention. This flow chart is used for locating zinc alloy and zinc metal ingots. In the implementation process, (1) first create a template image of the ingot, and use the template image to detect the position of a single ingot, (2) then calculate all the ingots on the image according to the characteristics of equal intervals between adjacent ingots (3) Then use the sobel operator to detect the linear features o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com