Semiconductor transistor die bonding auxiliary equipment

A technology for auxiliary equipment and transistors, which is used in semiconductor/solid-state device manufacturing, cleaning methods using gas flow, electrical components, etc., and can solve problems affecting patch accuracy and transistor transfer belt displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

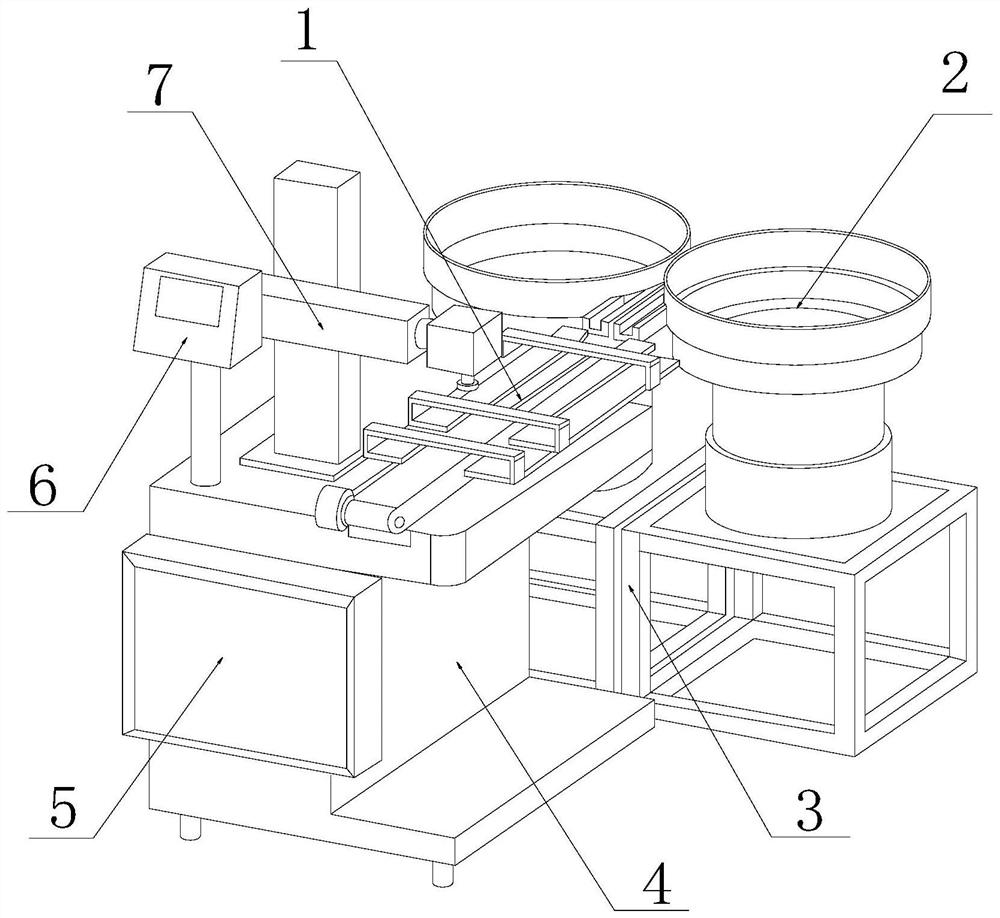

[0026] as attached figure 1 to attach Figure 5 Shown:

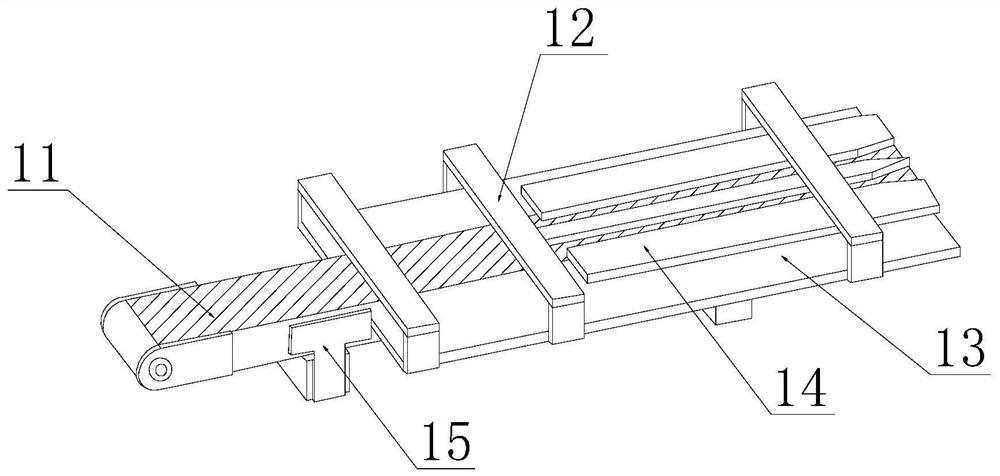

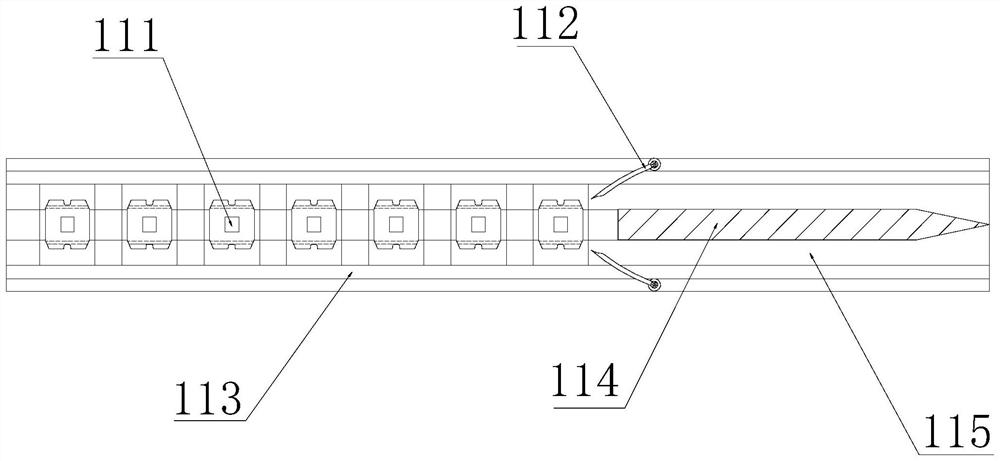

[0027] Its structure includes a conveyor 1, a feeding trough 2, a support platform 3, a carrier platform 4, an equipment box 5, a controller 6, and a film sticking head 7. 3 is fixed with bolts at the bottom of the lower chute 2, the carrier platform 4 is in clearance fit with the left side of the support platform 3, the carrier platform 4 is movably matched with both sides of the conveyor 1, and the carrier platform 4 is matched with the left side of the equipment box 5 Embedded connection, the controller 6 is fixed on the upper surface of the carrier 4 and nested with it, the adhesive head 7 is bolted to the upper surface of the carrier 4, the conveyor 1 is movably matched with the top of the adhesive head 7, the The conveyor 1 includes a conveyor belt 11, an air supply frame 12, a fixed plate 13, a limit block 14, and a support seat 15. The center is nested and connected, the surface of the fixed plate 13 is bolted...

Embodiment 2

[0034] as attached Image 6 to attach Figure 7 Shown:

[0035] Wherein, the air supply frame 12 includes a support frame 121, an air duct 122, and an air outlet column 123, the bottom surface of the support frame 121 is integrally connected with the air duct 122 by bolts, and the surface of the air duct 122 cooperates with the inside of the air outlet column 123. , the support frame 121 is connected with bolts at the top of the air outlet column 123, and the air outlet column 123 is provided with three elliptical cylinders, which are small at the top and large at the bottom, distributed on the lower surface of the support frame 121, and fixed with the bolts, wherein The column 123 is beneficial to cooperate with the air duct 122 to blow off the dust and debris on the surface of the transistor and the surroundings, so as to ensure that there will be no problem of sticking or not sticking the chips when bonding the chips.

[0036] Wherein, the air outlet column 123 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com