Irrigation equipment for municipal garden maintenance

A garden and municipal technology, applied in the field of irrigation devices, can solve problems such as failure to achieve efficient utilization of resources, and achieve the effect of reducing wear and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

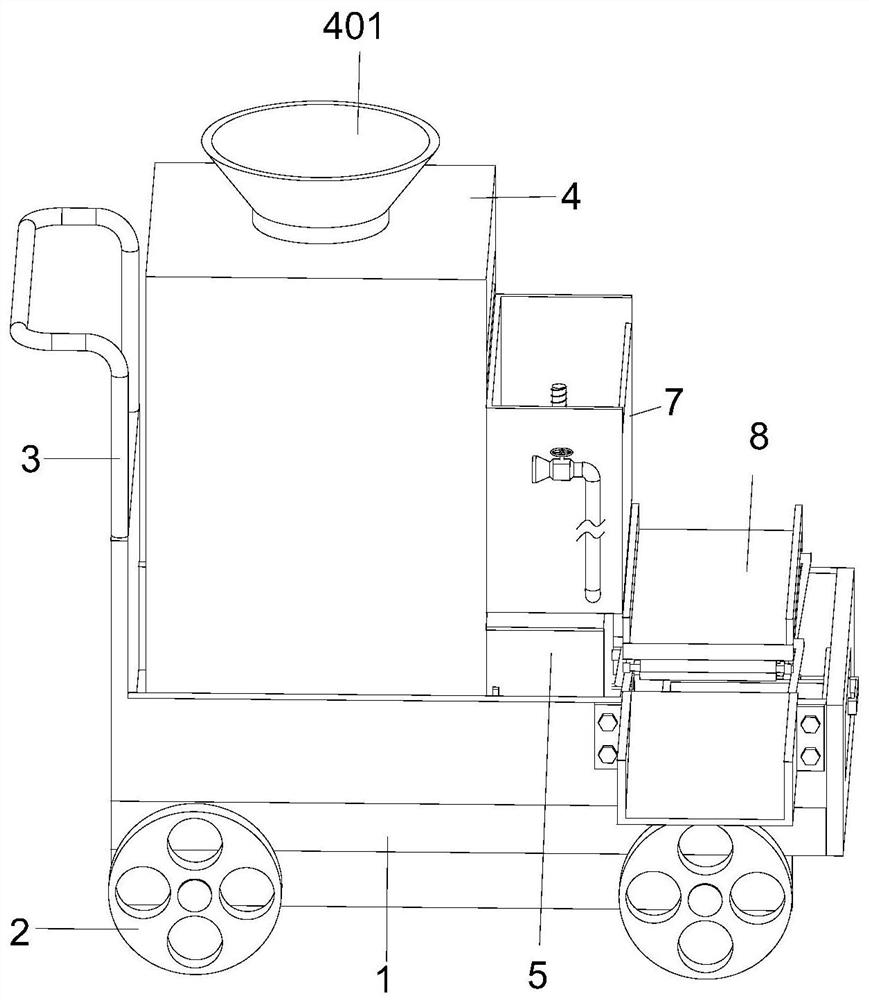

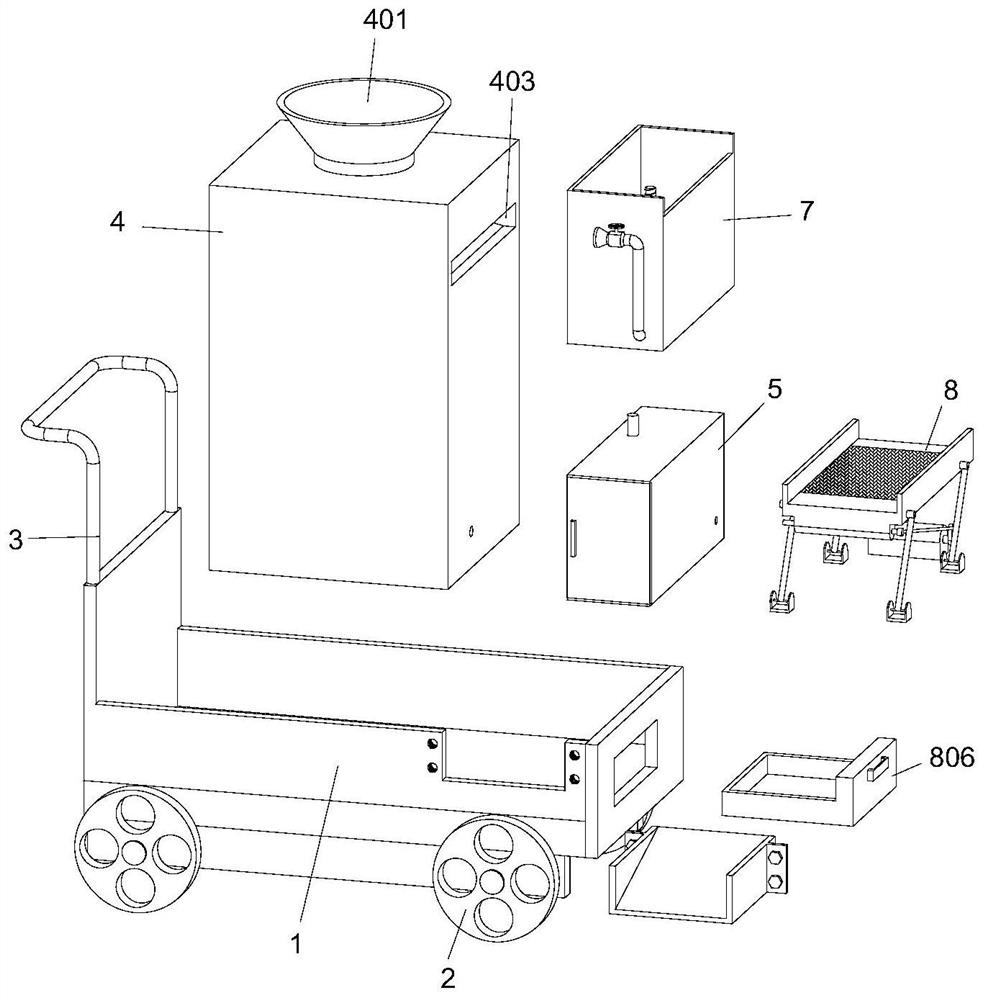

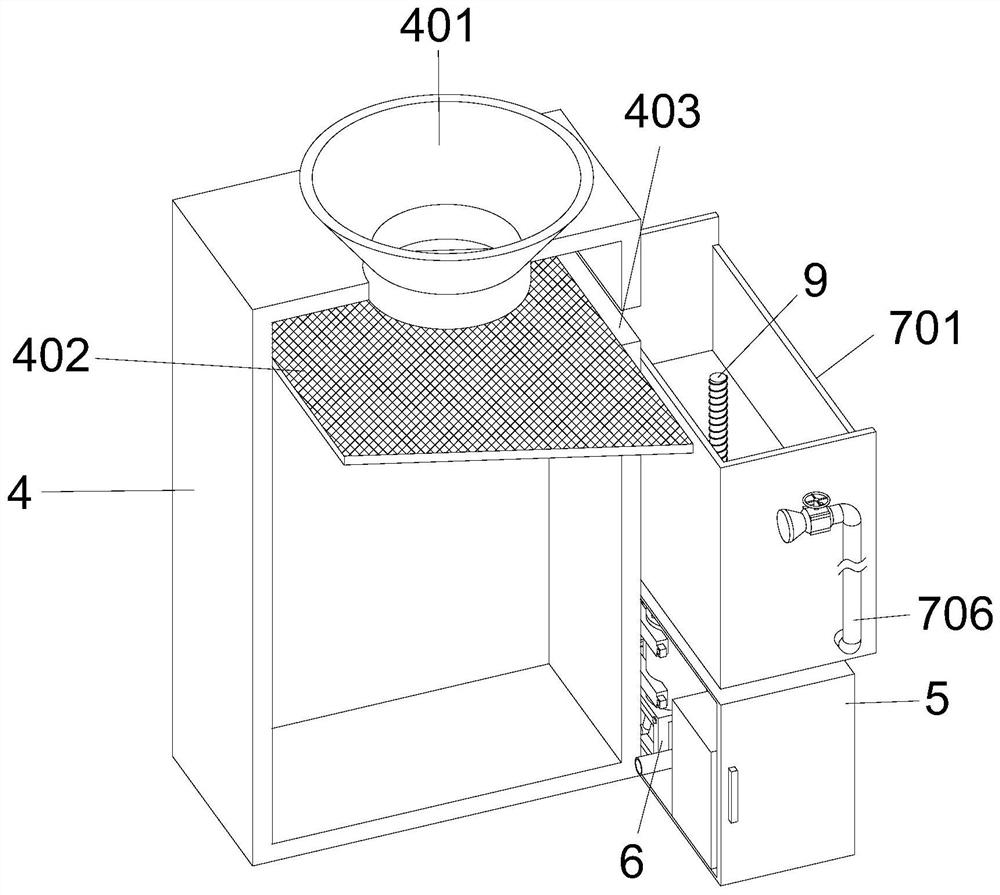

[0031] see Figure 1-4 , a kind of irrigation equipment for municipal garden maintenance, comprising a car body 1, two wheels 2 are arranged on the bottom of the front and rear sides of the car body 1, a handrail 3 is provided on the top of the rear end of the car body 1, and a Water tank 4, the top surface of water tank 4 is provided with water tank 401, and the inside of water tank 4 is left high with respect to the position below water tank 401 and right bottom structure is fixedly provided with filter screen 402, and the position of water tank 4 right end is provided with relative to the position of filter screen 402 right end A filter tank 403, a power box 5 is provided at the bottom of the right end of the water tank 4, a power assembly 6 is provided inside the power box 5, a garbage disposal module 7 is provided at the right end of the water tank 4 relative to the position below the filter tank 403, and a right end top surface of the vehicle body 1 is provided with Shak...

Embodiment 2

[0035] see Figure 4-5The difference in the basis of Embodiment 1 is that the garbage disposal module 7 includes a garbage bin 701, the garbage bin 701 is fixed at the position below the filter tank 403, and the middle part of the bottom end of the garbage bin 701 is fixed with a water pressure box 702 , the water pressure box 702 is set in a hollow cylindrical structure, the inside of the water pressure box 702 is provided with a rotating seat 703, and the outer wall of the rotating seat 703 is annular and equidistantly fixed with a plurality of water baffles 704, and the front and rear ends of the water pressure box 702 Two drainage holes 705 are symmetrically opened in the center. The drainage holes 705 are internally connected with a drainage pipe 706. A rotary box 707 is fixed in the middle of the top surface of the water pressure box 702. A coil spring 708 is fixed on the inner wall of the rotary box 707. Above the rotary box 707 A pallet 709 is provided.

[0036] The g...

Embodiment 3

[0039] see Figure 6 , the difference between the foundations of Embodiments 1 and 2 is that the water inlet pipe of the booster pump 601 extends to the inside of the water tank 4, and the drain pipe 706 on the rear side extends through the bottom surface of the dustbin 701 to the inside of the power box 5 and is connected with the booster pump. The water outlet of the pressure pump 601 is connected and fixed, and the drain pipe 706 at the front side extends through the front end of the dustbin 701 to its front side.

[0040] The vibrating screen module 8 includes a vibrating screen plate 801 located at the lower left side of the dustbin 701. The vibrating screen plate 801 is arranged in an inclined structure with a rear height and a front bottom. Two hinge seats 802 are provided, and the hinge seats 802 are rotationally connected with the vibrating screen plate 801 through connecting rods. The front bottom surface of the vibrating screen plate 801 is provided with a rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com