Tobacco shred fully-closed temperature-equalizing and humidity-equalizing method and equipment

A fully enclosed and shredded tobacco technology, which is applied in the tobacco industry, can solve the problems of excessive moisture and achieve the effect of small crushing and unbalanced temperature and humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

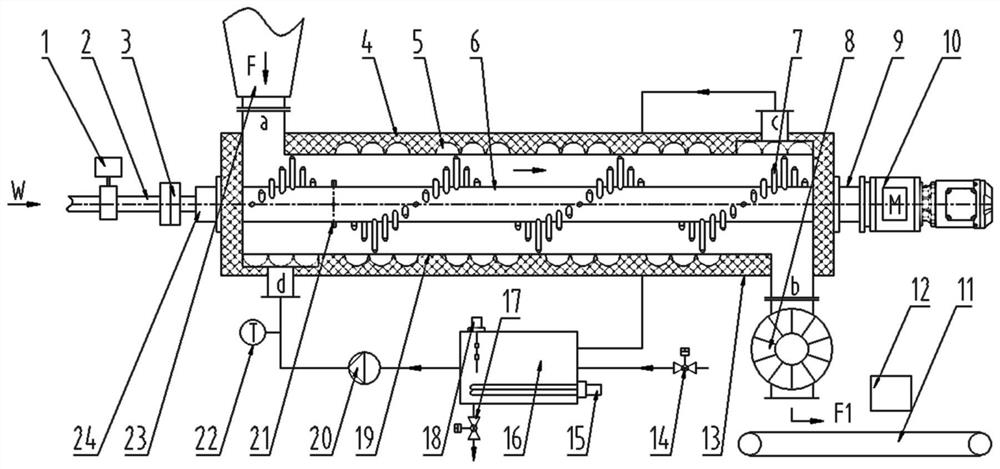

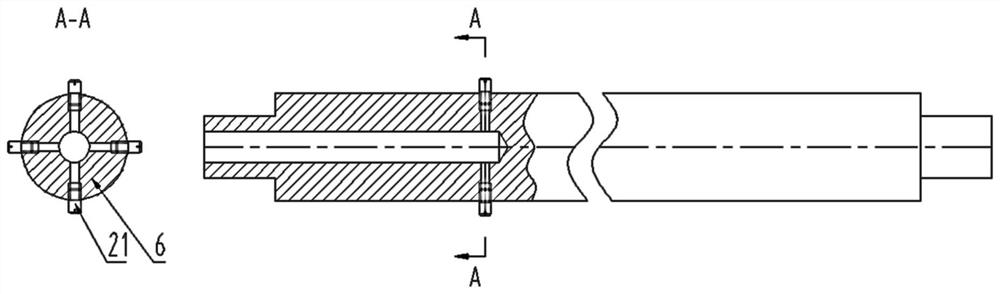

[0023] to combine figure 1 Describe the structure of the shredded tobacco fully-enclosed uniform temperature and humidity equipment of the present invention. The shredded tobacco fully enclosed uniform temperature and humidity equipment of the present invention is equipped with a humidification system and a heating system, wherein the humidification system uses the humidification pipe 2 outside the equipment casing and the humidification nozzle 21 installed on the main shaft 6 to realize the adjustment and humidification of the shredded tobacco humidity. The pipe 2 communicates with the humidification nozzle 21 through the axial hole and the radial hole of the main shaft 6 . The heating system then adopts the heating water tank 16 and the heating half-pipe 5 that is spirally distributed on the outer wall of the equipment casing to realize the adjustment of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com