Highly-integrated modular collaboration robot joint module

A robot joint and highly integrated technology, applied in the field of robotics, can solve the problems of low integration, bulky size, and loose threads at the joints, and achieve the effects of saving internal space, small overall volume, and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

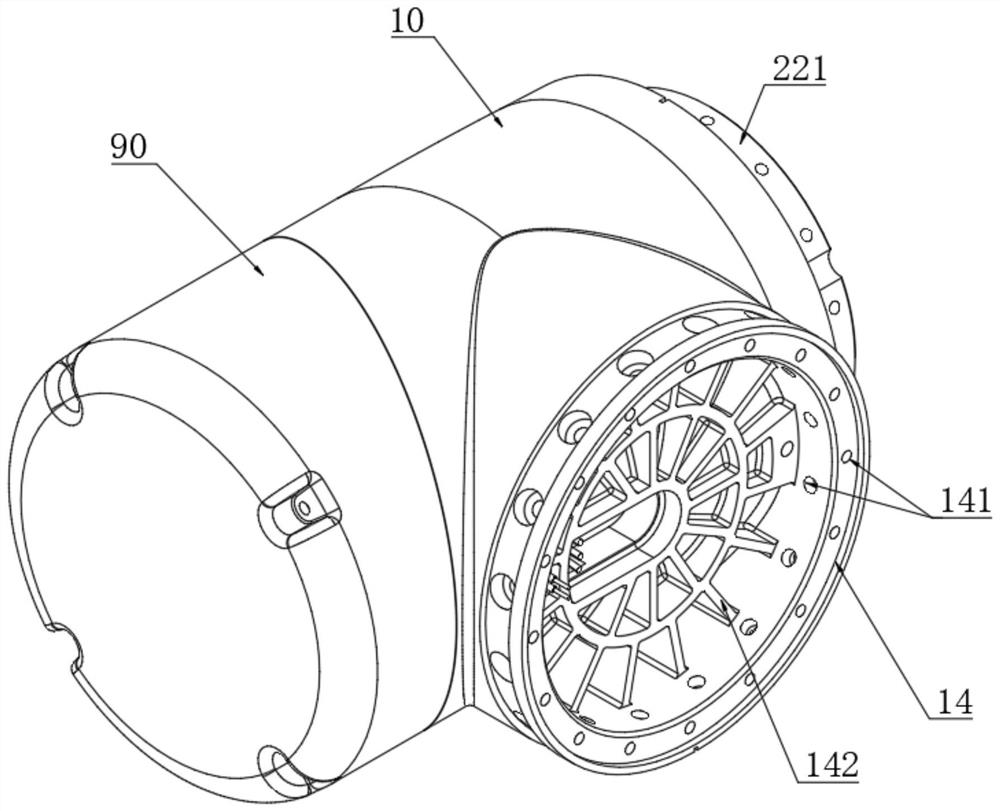

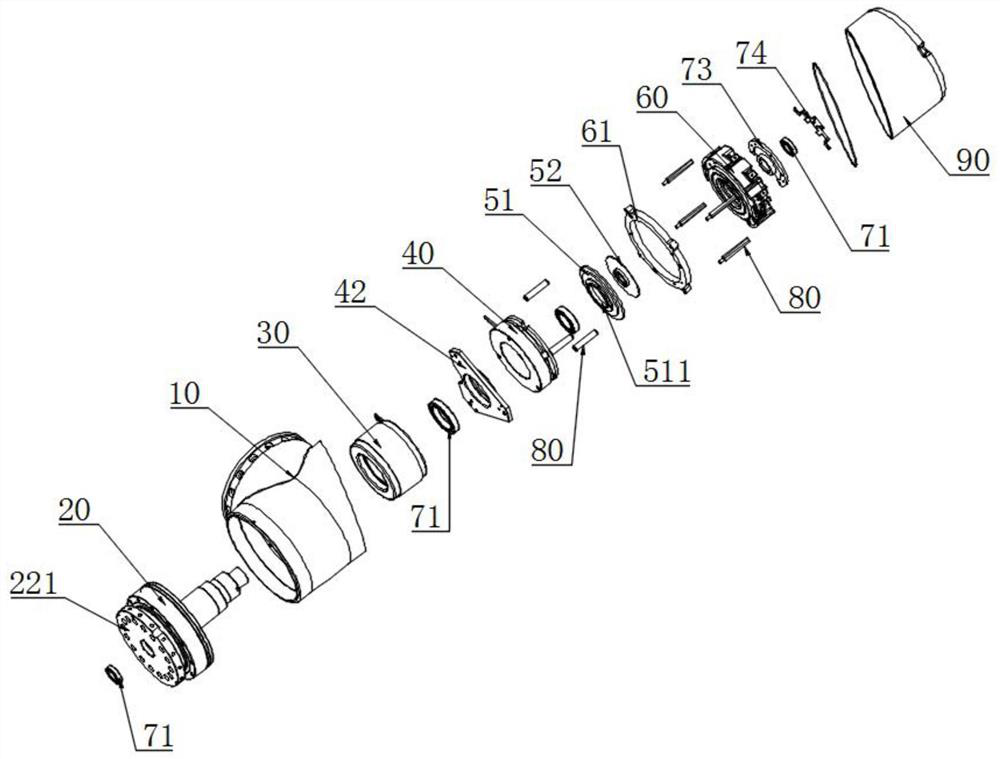

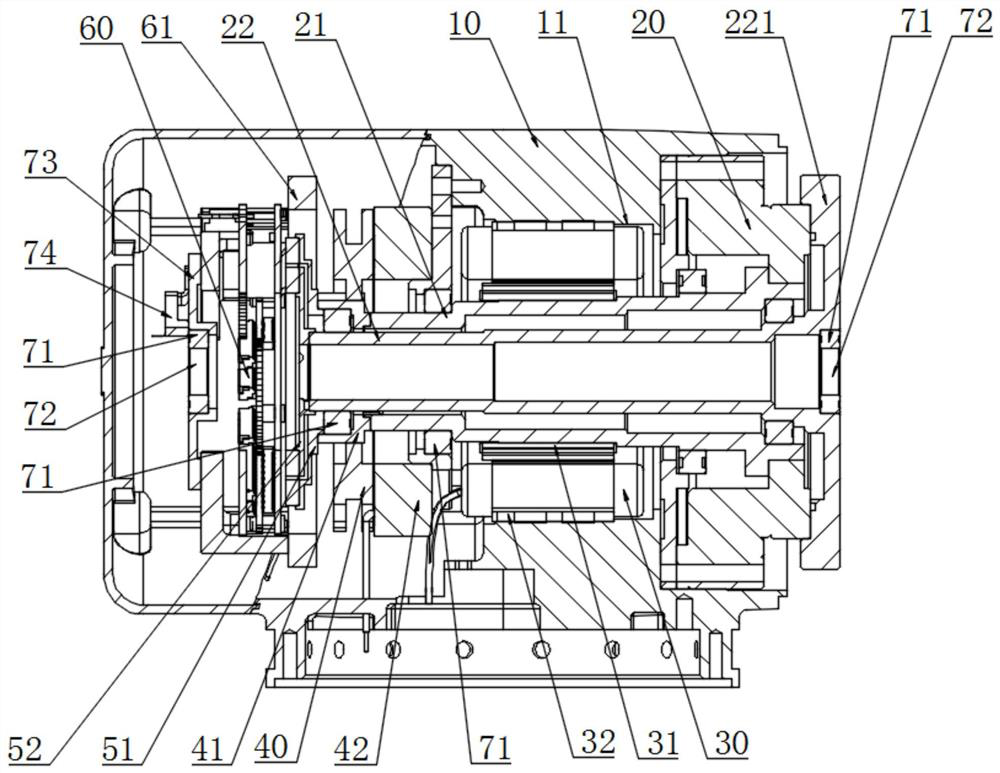

[0044] see Figure 1 to Figure 6 , a highly integrated modular collaborative robot joint module in this embodiment, including a joint body 10, a harmonic reducer 20, a frameless torque motor 30, a brake 40, an encoder, a driver 60 and a joint cover 90;

[0045]The harmonic reducer 20 , frameless torque motor 30 , brake 40 , encoder, and driver 60 are sequentially arranged on the joint body 10 along the same axial direction; the frameless torque motor 30 and brake 40 are sequentially arranged on the input shaft 21 superior.

[0046] Specifically, the joint body 10 is provided with a connection part 14 connected with other joint bodies 10; the connection part 14 is respectively provided with installation positioning holes 141 along its axial direction and radial direction; ;By adopting the overall modular design, the connecting part 14 is designed with axial and radial positioning and connecting holes, which can not only realize the rapid splicing between the joints of the coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com