A protective medium density fiberboard thermal mill and its working method

A thermal mill, medium-density technology, applied in the manufacture of tools, wood processing appliances, etc., can solve the problems of thermal mills susceptible to impact damage, short use time of grinding discs, easy damage, etc., to avoid exposure and collapse, The equipment has high practicability and the effect of improving the use time limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

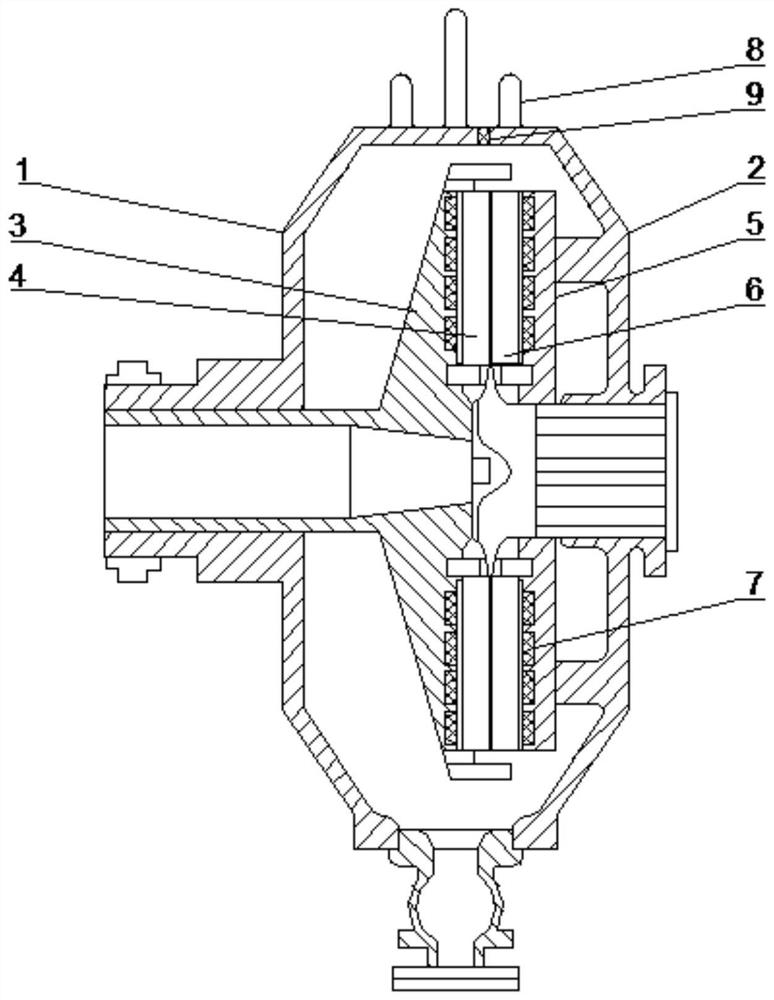

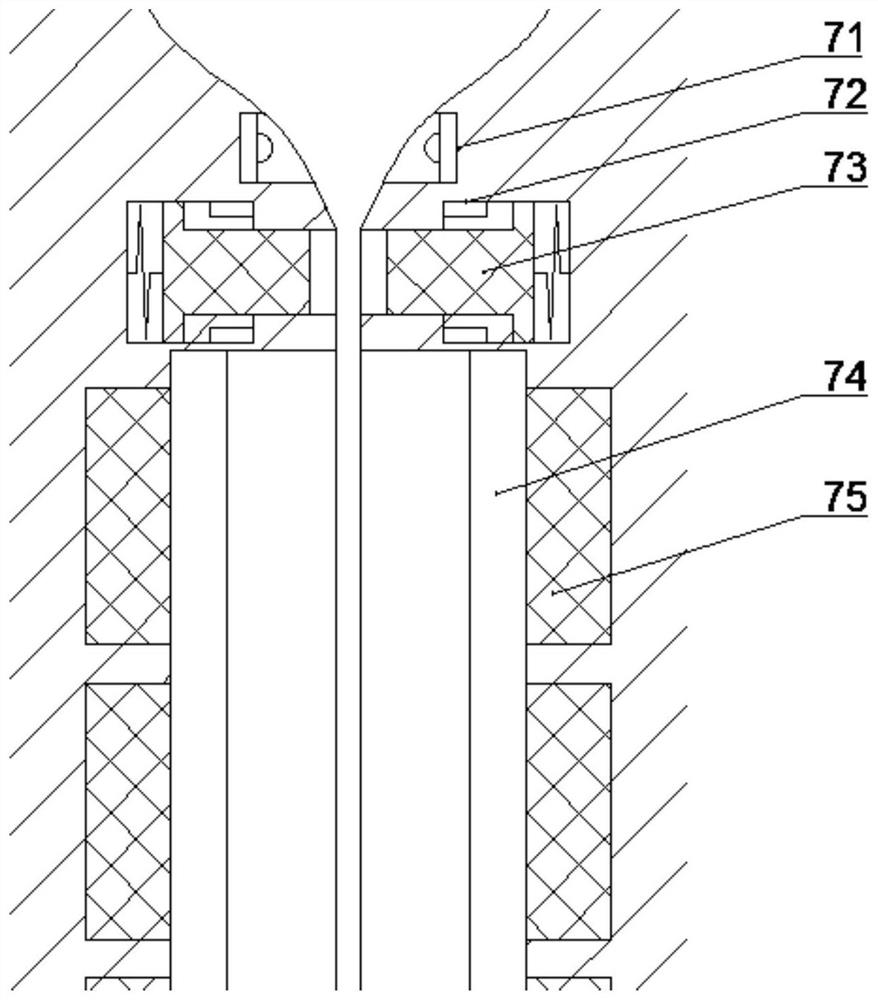

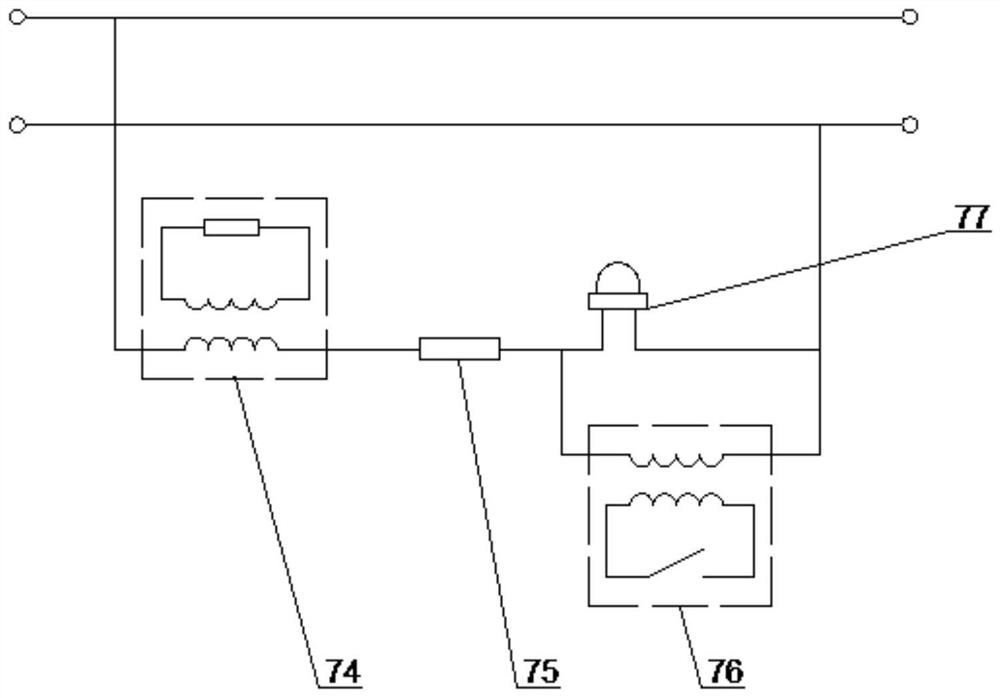

[0037] Such as Figure 1-6 A protective medium density fiberboard thermal grinder is shown, including: a thermal grinder shell 1, a cover plate 2, a movable grinding disc 3, a movable grinding disc 4, a fixed grinding disc 5, a fixed grinding disc 6, and a grinding disc protection mechanism 7 and the shell protective cover 8, a movable grinding disc 3 is arranged in the said thermal grinding machine shell 1, and a movable grinding disc grinding plate 4 is arranged on the said thermal grinding machine shell 1; a cover plate 2 is arranged on one side of said thermal grinding machine shell 1, The cover plate 2 cooperates with the heat mill shell 1, and the fixed grinding disc 5 is arranged in the described cover plate 2, and the fixed grinding disc 5 is provided with a fixed grinding disc grinding disc 6, and the fixed grinding disc grinding disc 6 is connected with the movable grinding disc grinding disc. 4 is matched; the moving grinding disc 3 is provided with a grinding disc ...

Embodiment 2

[0049] Such as Figure 1-3 A protective medium density fiberboard thermal grinder is shown, including: a thermal grinder shell 1, a cover plate 2, a movable grinding disc 3, a movable grinding disc 4, a fixed grinding disc 5, a fixed grinding disc 6, and a grinding disc protection mechanism 7 and the shell protective cover 8, a movable grinding disc 3 is arranged in the said thermal grinding machine shell 1, and a movable grinding disc grinding plate 4 is arranged on the said thermal grinding machine shell 1; a cover plate 2 is arranged on one side of said thermal grinding machine shell 1, The cover plate 2 cooperates with the heat mill shell 1, and the fixed grinding disc 5 is arranged in the described cover plate 2, and the fixed grinding disc 5 is provided with a fixed grinding disc grinding disc 6, and the fixed grinding disc grinding disc 6 is connected with the movable grinding disc grinding disc. 4 is matched; the moving grinding disc 3 is provided with a grinding disc ...

Embodiment 3

[0053] Such as figure 1 and 4 A protective medium density fiberboard thermal grinder is shown, including: a thermal grinder shell 1, a cover plate 2, a movable grinding disc 3, a movable grinding disc 4, a fixed grinding disc 5, a fixed grinding disc 6, and a grinding disc protection mechanism 7 and the shell protective cover 8, a movable grinding disc 3 is arranged in the said thermal grinding machine shell 1, and a movable grinding disc grinding plate 4 is arranged on the said thermal grinding machine shell 1; a cover plate 2 is arranged on one side of said thermal grinding machine shell 1, The cover plate 2 cooperates with the heat mill shell 1, and the fixed grinding disc 5 is arranged in the described cover plate 2, and the fixed grinding disc 5 is provided with a fixed grinding disc grinding disc 6, and the fixed grinding disc grinding disc 6 is connected with the movable grinding disc grinding disc. 4 is matched; the moving grinding disc 3 is provided with a grinding d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com