Processing method of TPU high-low temperature film composite cloth

A technology of high and low temperature film and processing method, applied in the processing field of TPU high and low temperature film composite cloth, can solve the problems of high cost of multiple combined molds and high mold opening cost, and achieve the effect of saving production cost and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A processing method of TPU high and low temperature film composite cloth, comprising the following steps:

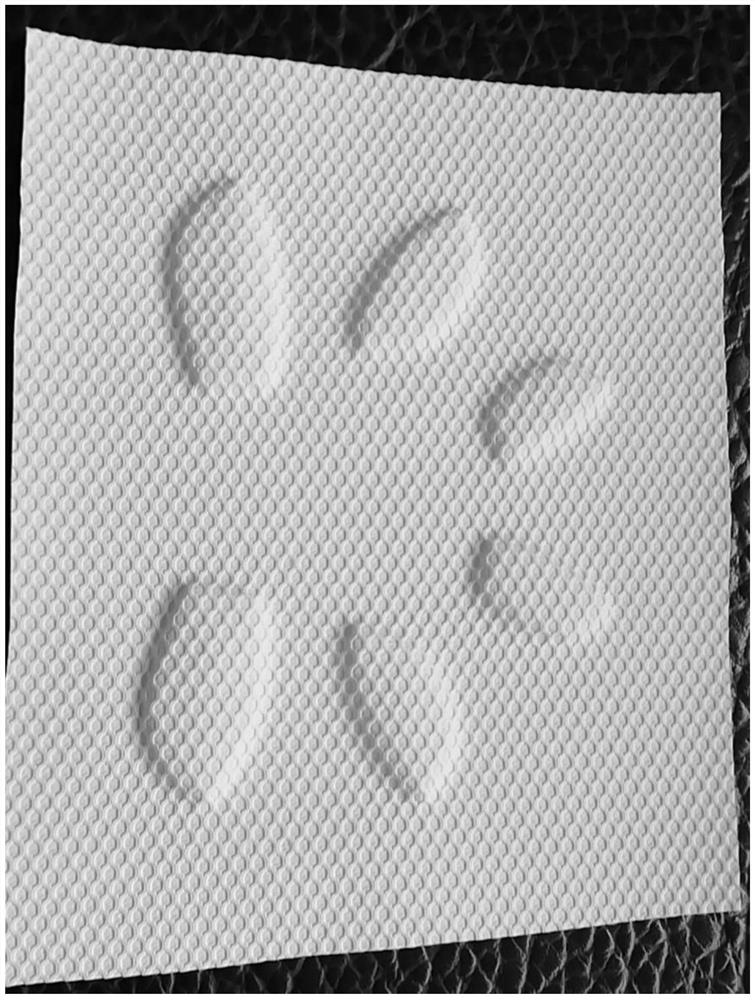

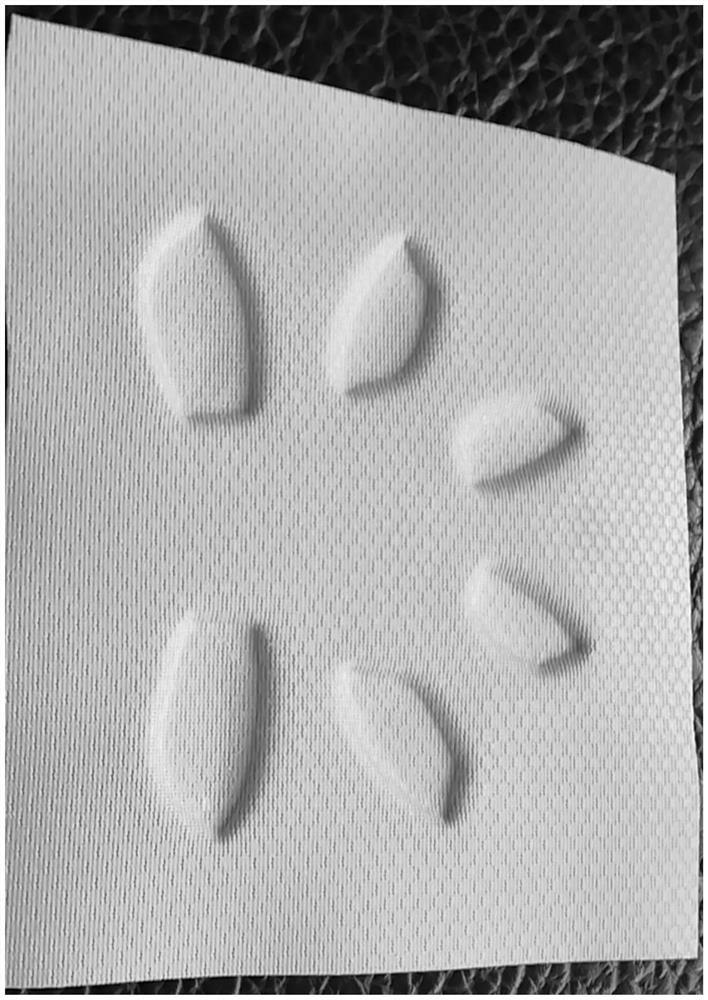

[0025] (S1), take the tool and place it on the stage of the hot pressing equipment, and then take the TPU high and low temperature film and arrange it on the surface of the tool; wherein, the side of the tool where the TPU high and low temperature film composite cloth is placed is uneven flat;

[0026] (S2), pressing the soft heat-conducting layer of the hot-pressing equipment to the TPU high-low temperature film composite cloth for hot-pressing treatment, so that the TPU high-low temperature film composite cloth and the tool are pressed and deformed;

[0027] (S3) After hot pressing, the tool and the TPU high-low temperature film composite cloth are transferred as a whole to the stage of the shaping equipment for film setting treatment, and then the film is taken to obtain a three-dimensional TPU high-low temperature film composite cloth.

[0028] The processing...

Embodiment 2

[0043] The difference between embodiment 2 and embodiment 1 is:

[0044] In this embodiment, the tool is provided with a plurality of air guide holes, and the step (S2) further includes: vacuumizing during the hot-pressing treatment. The hot pressing equipment is a vacuum hot negative pressure blister machine with a soft heat conducting layer.

[0045] Adopting the above technical scheme, the TPU high and low temperature film composite cloth is promoted to be closely against the surface of the tool during the hot pressing process, and the shaping of the TPU high and low temperature film composite cloth is promoted, and the contour of the surface of the three-dimensional TPU high and low temperature film composite cloth is more perfect. fine.

[0046] In this embodiment, the soft heat-conducting layer is a heat-conducting silicone film with a thickness of 0.3-0.5 mm, which can be deformed according to the opening shape of the tool during vacuuming and negative pressure thermal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com