Patents

Literature

33results about How to "To achieve a three-dimensional effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

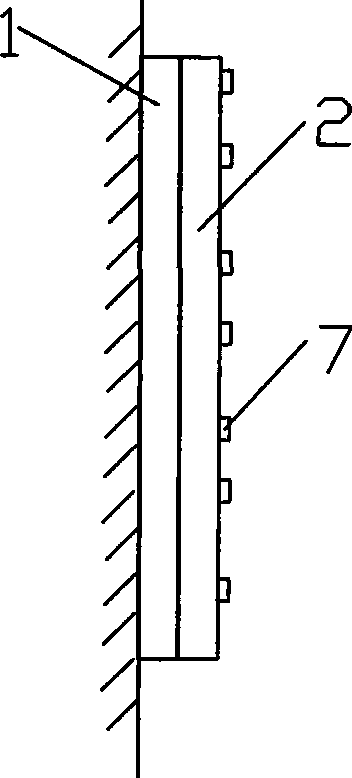

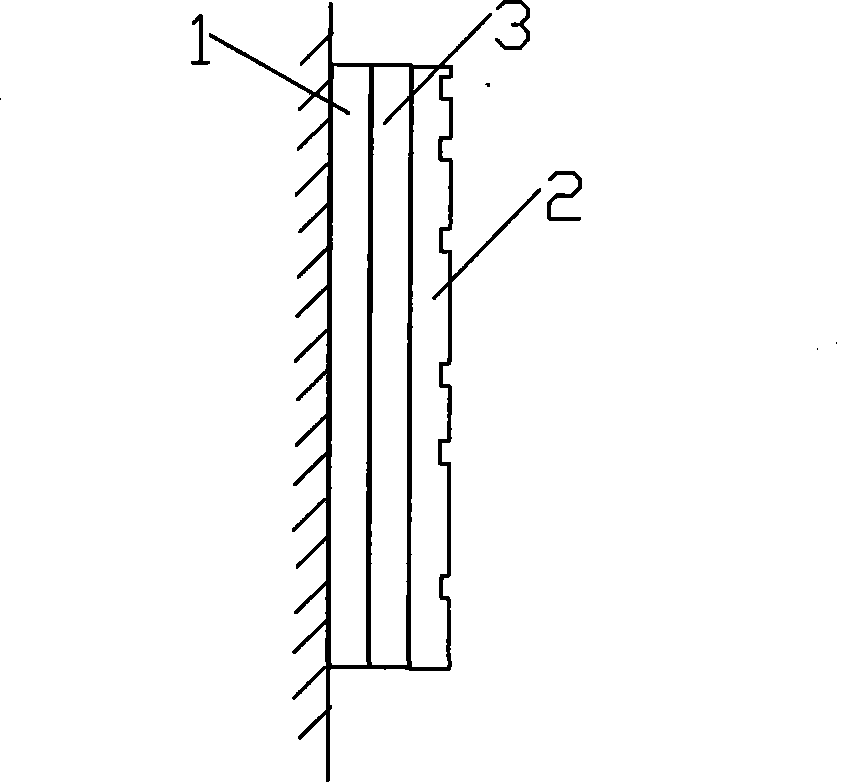

Wall cloth for decoration and preparation thereof

InactiveCN101387080AImprove the three-dimensional effectOrnamentalCovering/liningsLayered productsSurface layerEngineering

The invention relates to wall cloth for decoration. The wall cloth comprises a surface layer made of cloth, wherein one side of the surface layer is provided with a lining layer as well; the lining layer is fixed together with the surface layer; the wall cloth is fixed with a wall through the lining layer; and furthermore, an interlayer can be arranged between the surface layer and the lining layer, or the surface layer can be covered with an antibacterial coating, a flame-retardant coating and a protective coating. The invention also puts forward a method for manufacturing the wall cloth for decoration, which comprises the following steps of 1: spreading out and then laminating the lining layer and the surface layer, 2: fixing the surface layer and the lining layer so as to produce semi-finished wall cloth, 3: washing the produced semi-finished wall cloth and 4: drying the washed wall cloth so as to produce finished wall cloth. The wall cloth for decoration has the advantages that the wall cloth is free from pollution, good in hand feel, resistant to wear and durable, has various patterns and colors, can meet the requirements on individualized pattern design and large-area patterns, is low in cost and more convenient in manufacture and construction, and can be produced on a large scale.

Owner:黄桔英

Mobile phone cover glass main printing technology

The invention relates to the technical field of mobile phone cover glass printing, in particular to a mobile phone cover glass main printing technology. The mobile phone cover glass main printing technology comprises the steps of (1) primary mirror-like silver printing, wherein a mirror-like silver layer is printed on the lower surface of clear glass in a blade coating mode by means of the screen printing technique; (2) secondary bluish violet printing, wherein a second bluish violet layer is printed on the lower surface of the clear glass in a blade coating mode by means of the screen printing technique; (3) tertiary pearl white printing, wherein a pearl white layer is printed on the lower surface of the clear glass in a blade coating mode by means of the screen printing technique. According to the mobile phone cover glass main printing technology, by means of the composite printing technology conducted on the clear glass and combining the primary mirror-like silver printing, the secondary bluish violet printing and the tertiary pearl white printing, printed patterns are stereoscopic, and natural transition is achieved between different ink layers. The mobile phone cover glass main printing technology has the advantages that operation is simple and convenient to control, quality is stable, production efficiency is high, and large-scale industrial production can be achieved.

Owner:广东星弛光电科技有限公司

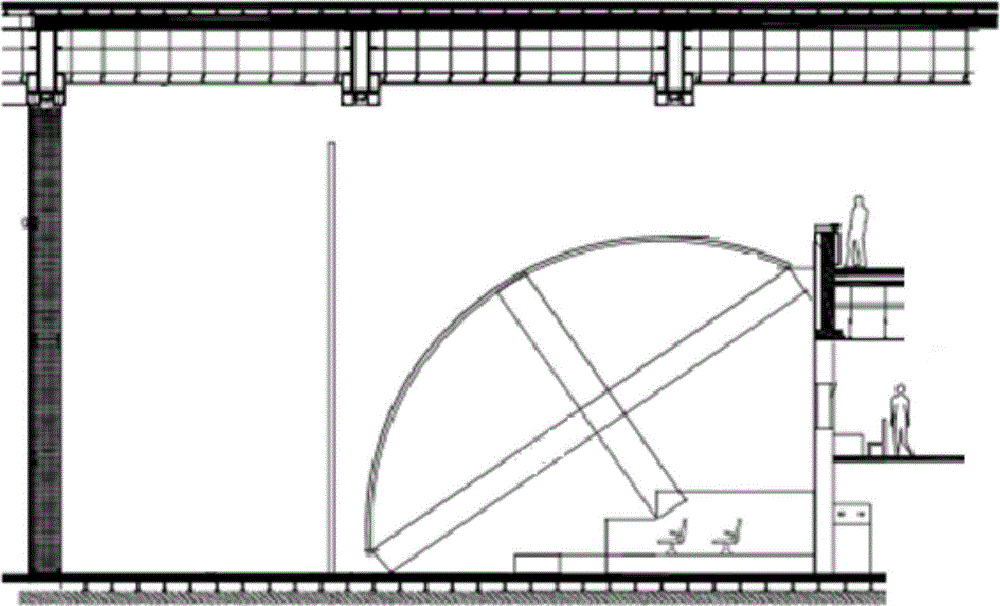

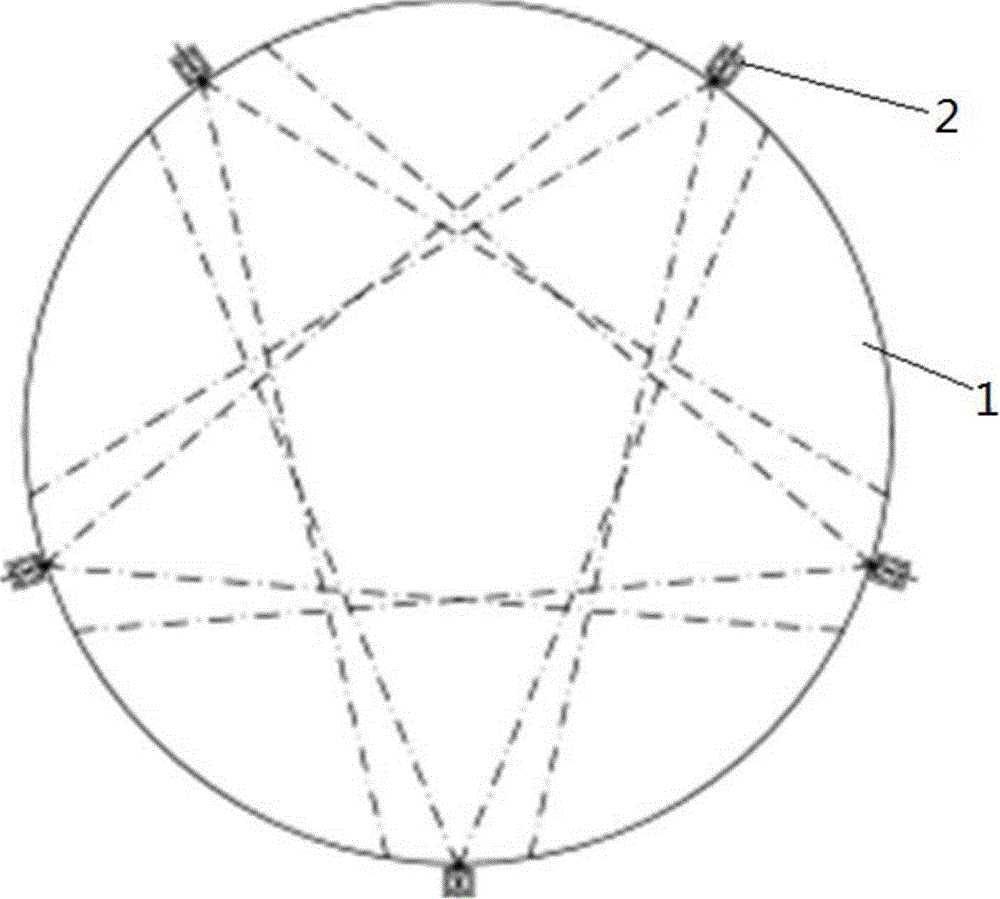

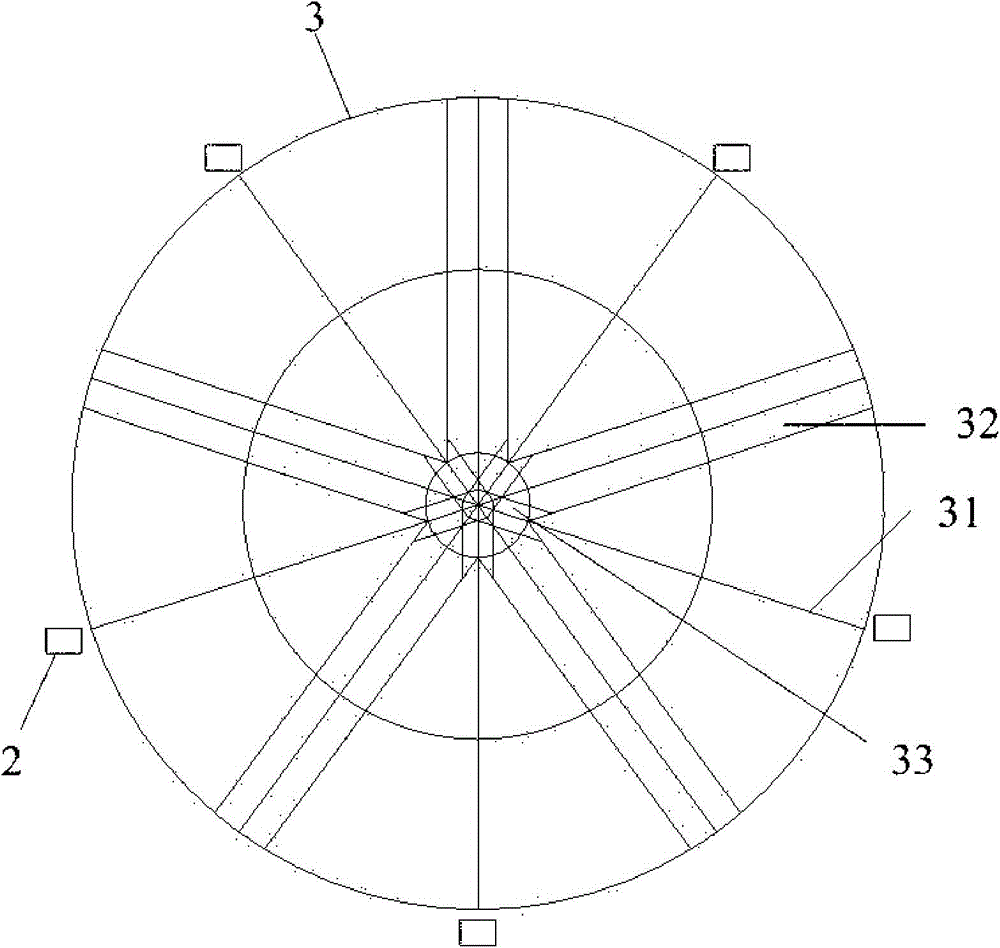

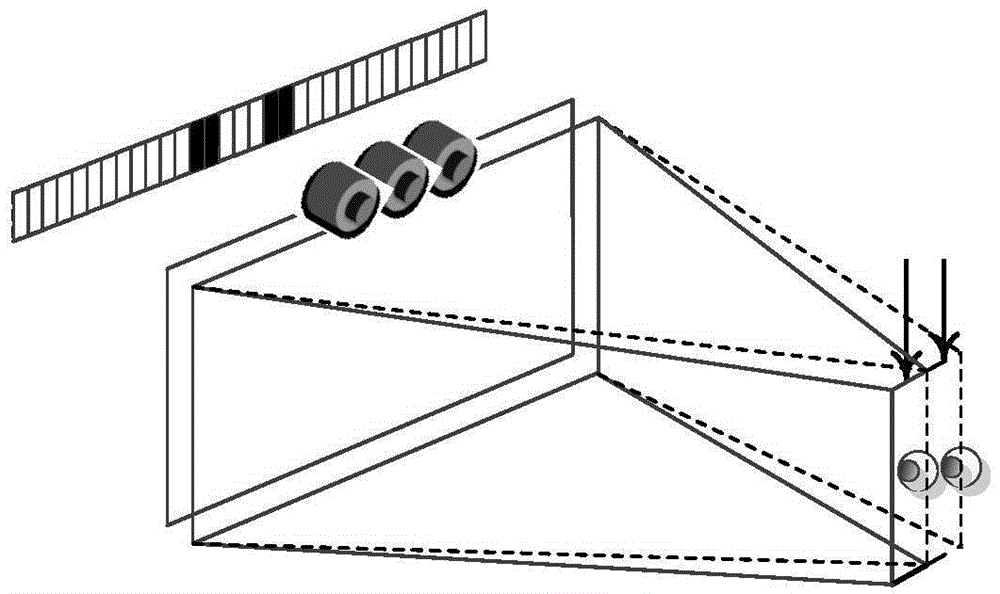

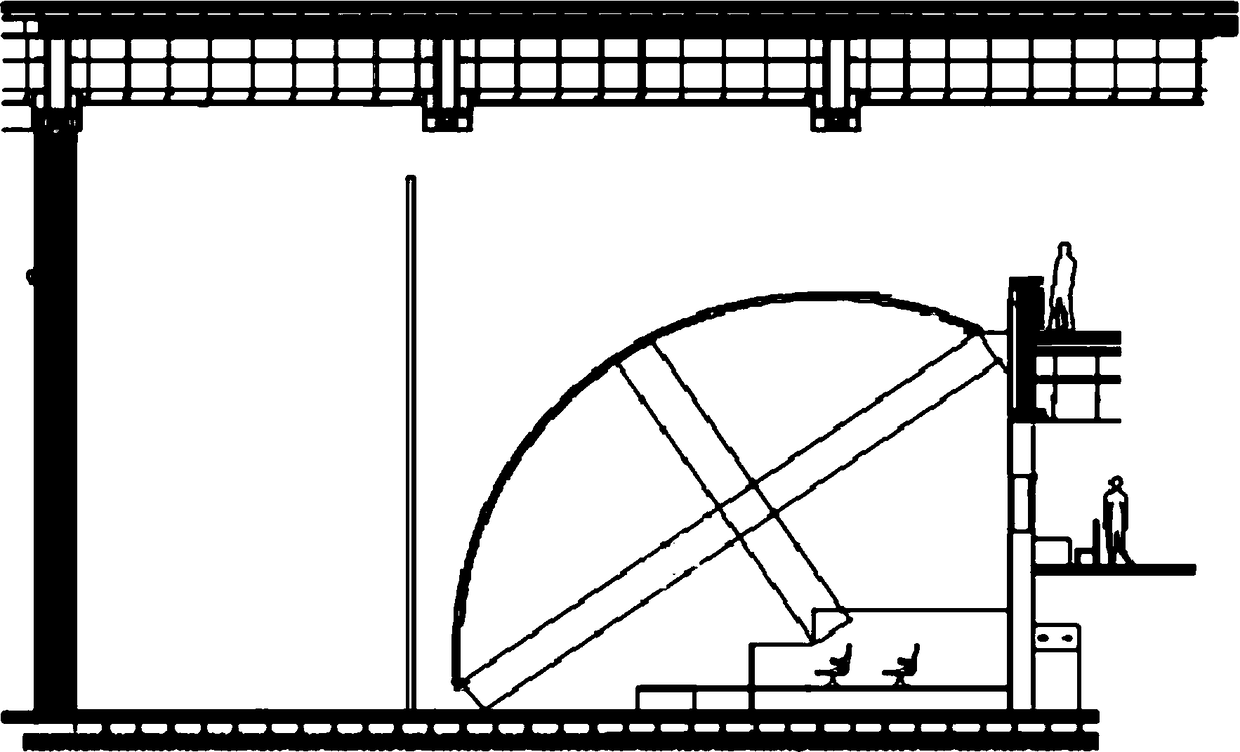

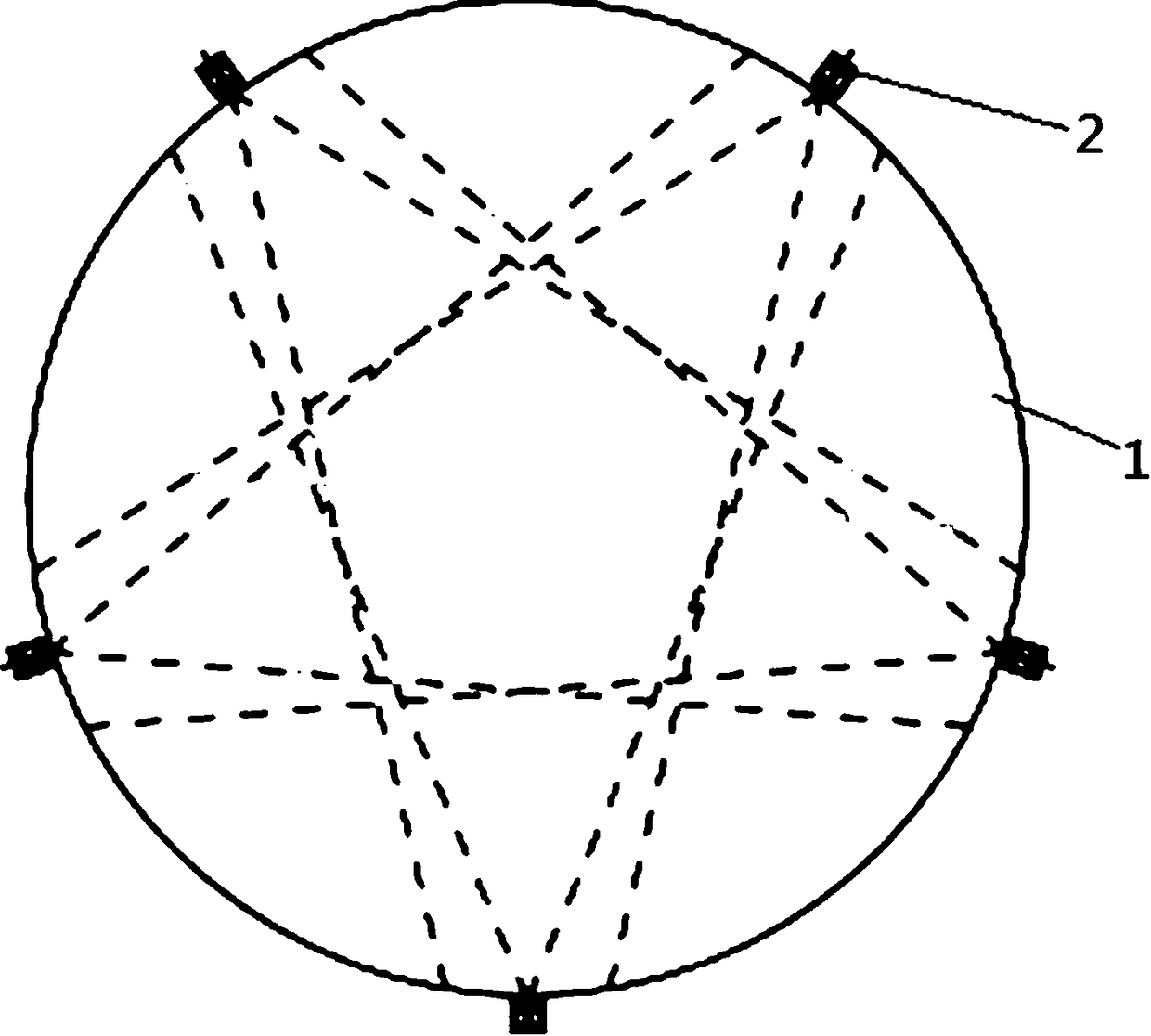

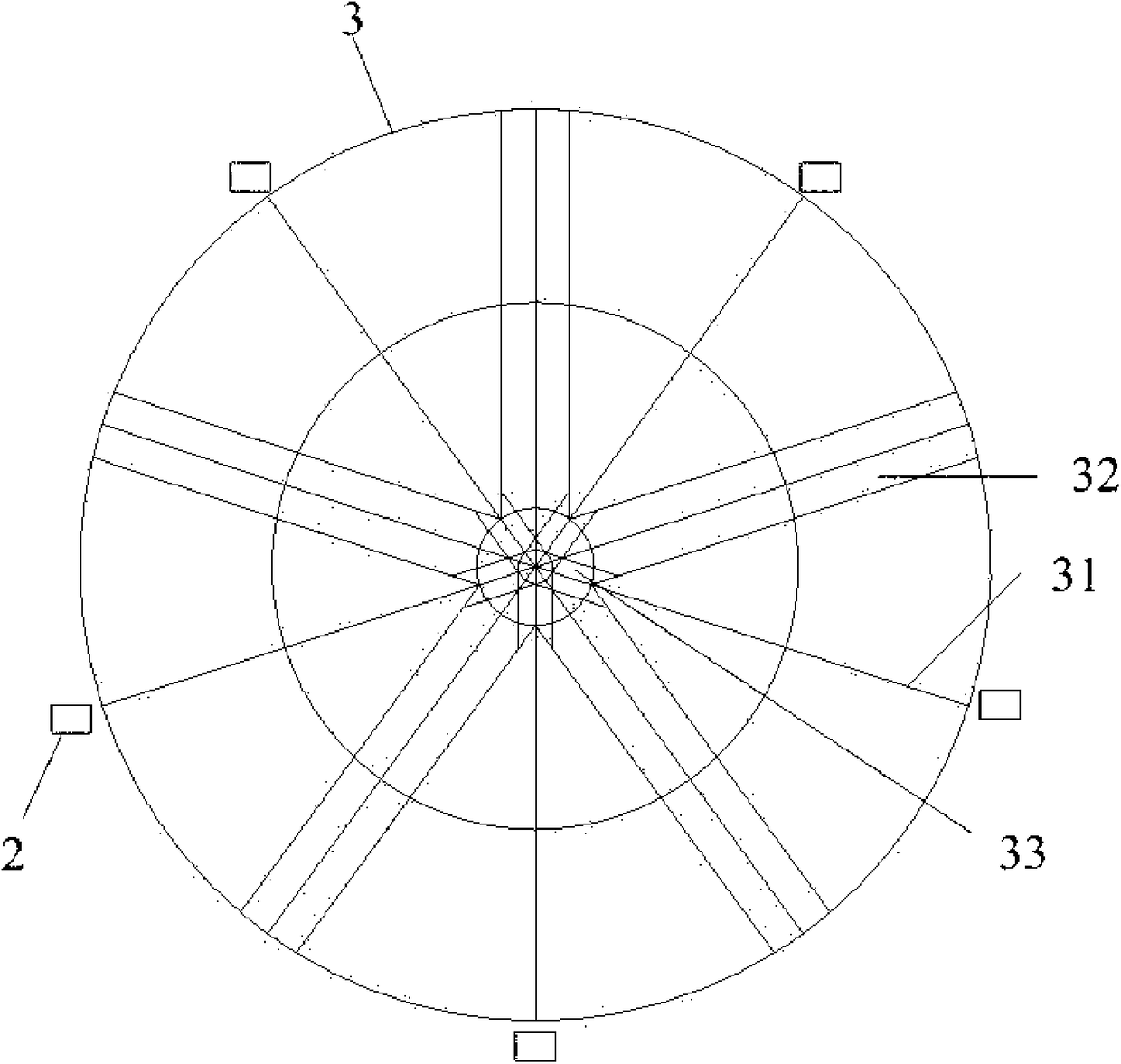

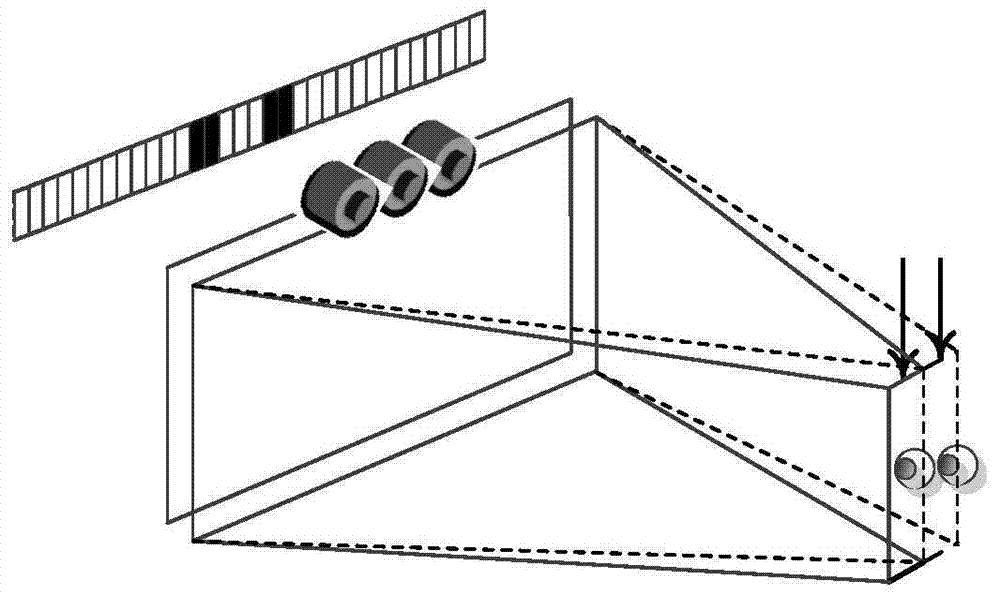

Realization method of stereoscopic spherical-screen projection system

ActiveCN104977796AOptimize seating arrangementInstallation Angle RestrictionsStereoscopic photographyPanoramic photographyProjection systemWorkload

The invention relates to a realization method of a stereoscopic spherical-screen projection system. The method comprises the following steps: 1) arranging a plurality of projection channels at the edge of a spherical screen body, wherein each projection channel is provided with two projectors; 2) generating a mesh model with a computer based on spherical screen curved surface, carrying out fan-shaped segmentation on the mesh model according to the number and position of the projection channels, and selecting an effective fan-shaped area for each projection channel; 3) carrying out curved surface correction and edge fusion on each fan-shaped area; 4) adjusting the positions of the projectors and combining computer fusion fine tuning, and realizing left and right eye splicing of the projection channels to enable the projection picture of each projection channel to cover the spherical screen curved surface completely; and 5) carrying out synchronous output and synchronous projection on multichannel pictures. The realization method of the stereoscopic spherical-screen projection system is small in projection picture and small in picture pixel loss, and ensures definition and brightness of the pictures; and meanwhile, by enabling the adjacent cutting regions to form a regular fusion band, workload of the later-period correction work is greatly reduced.

Owner:SHANGHAI HUABO INFORMATION SERVICE

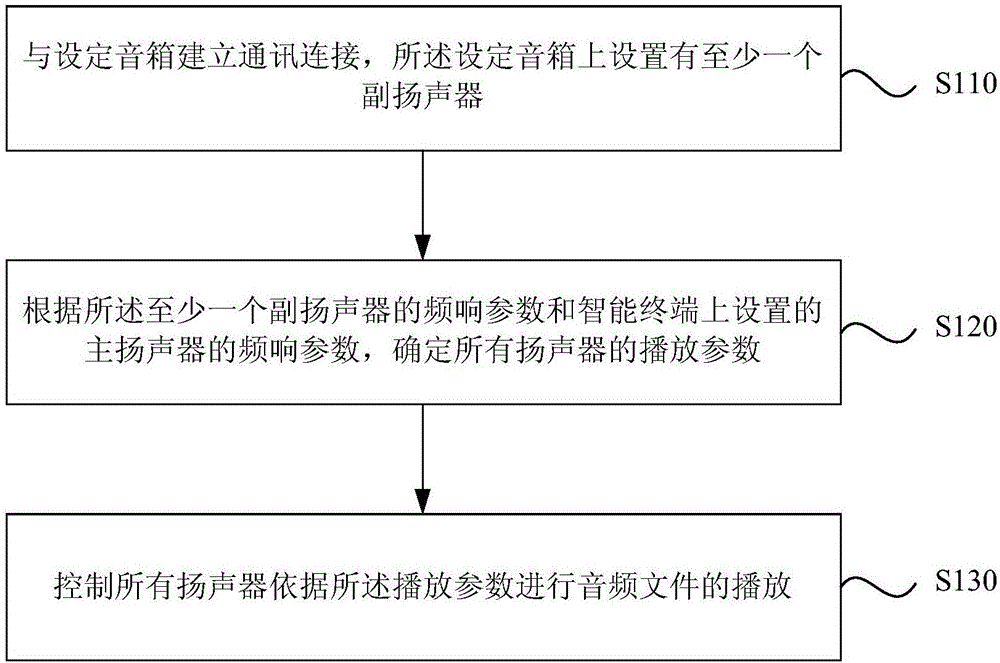

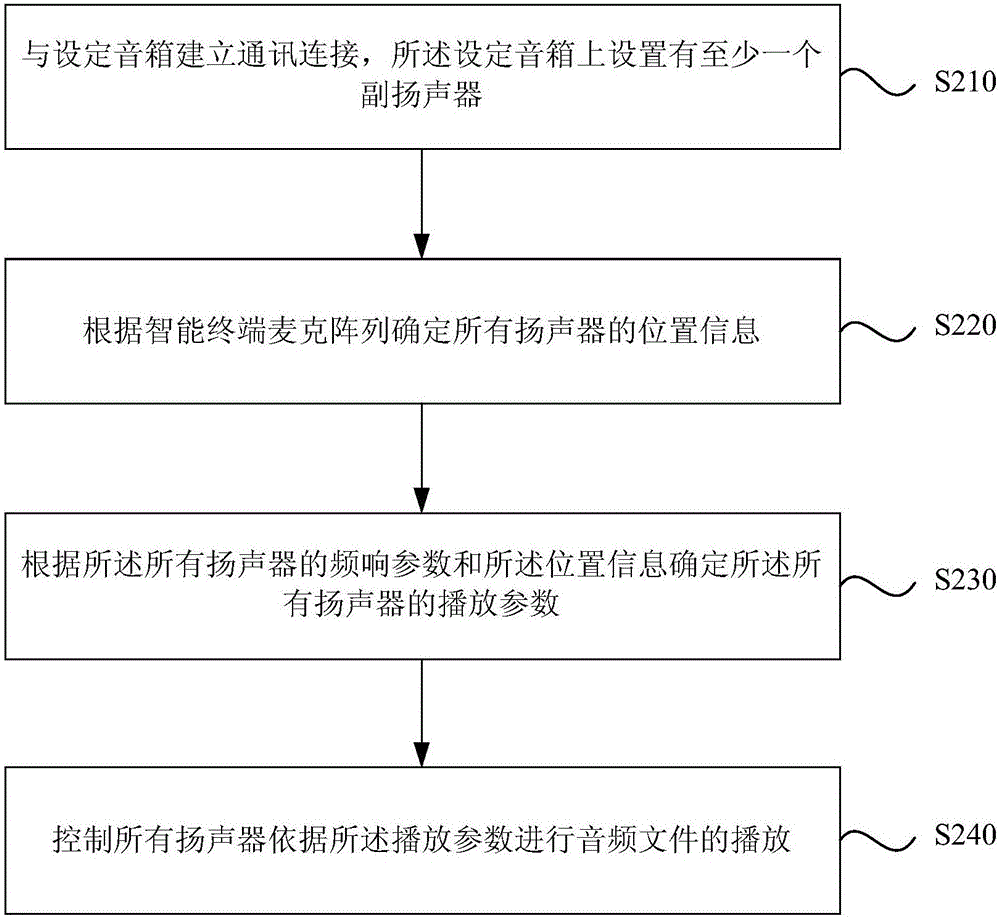

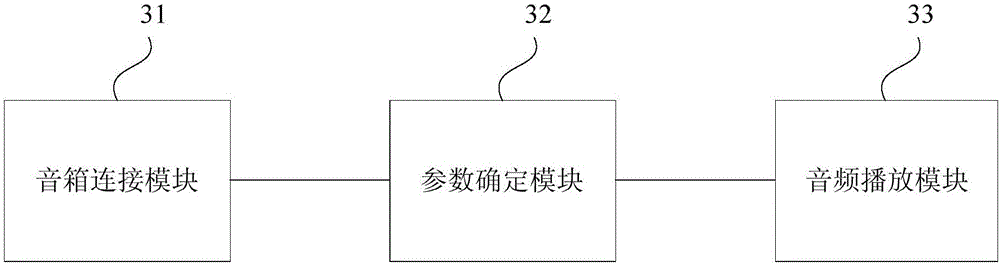

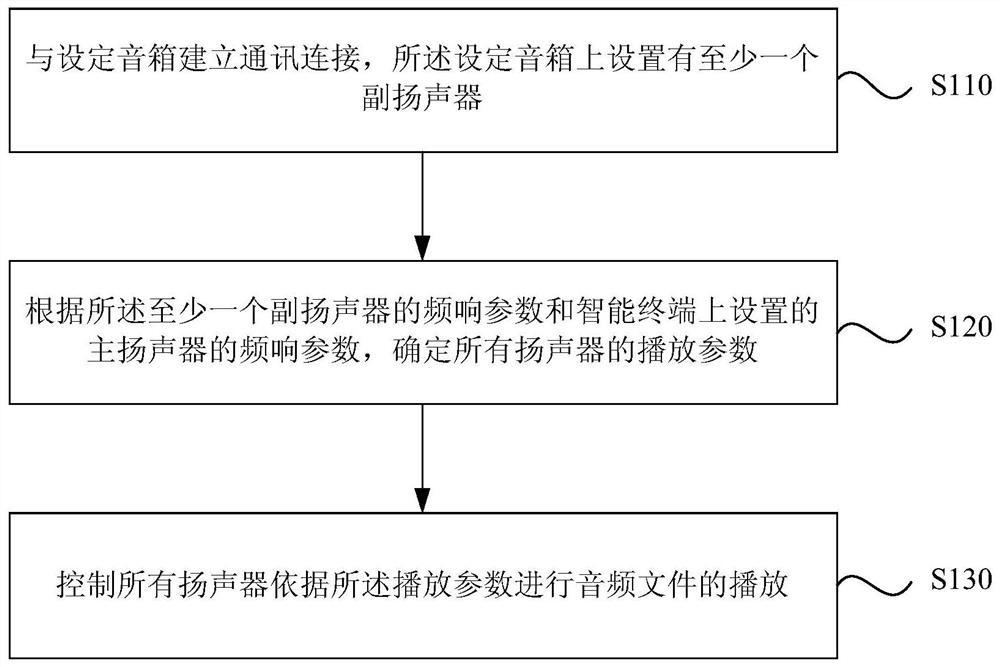

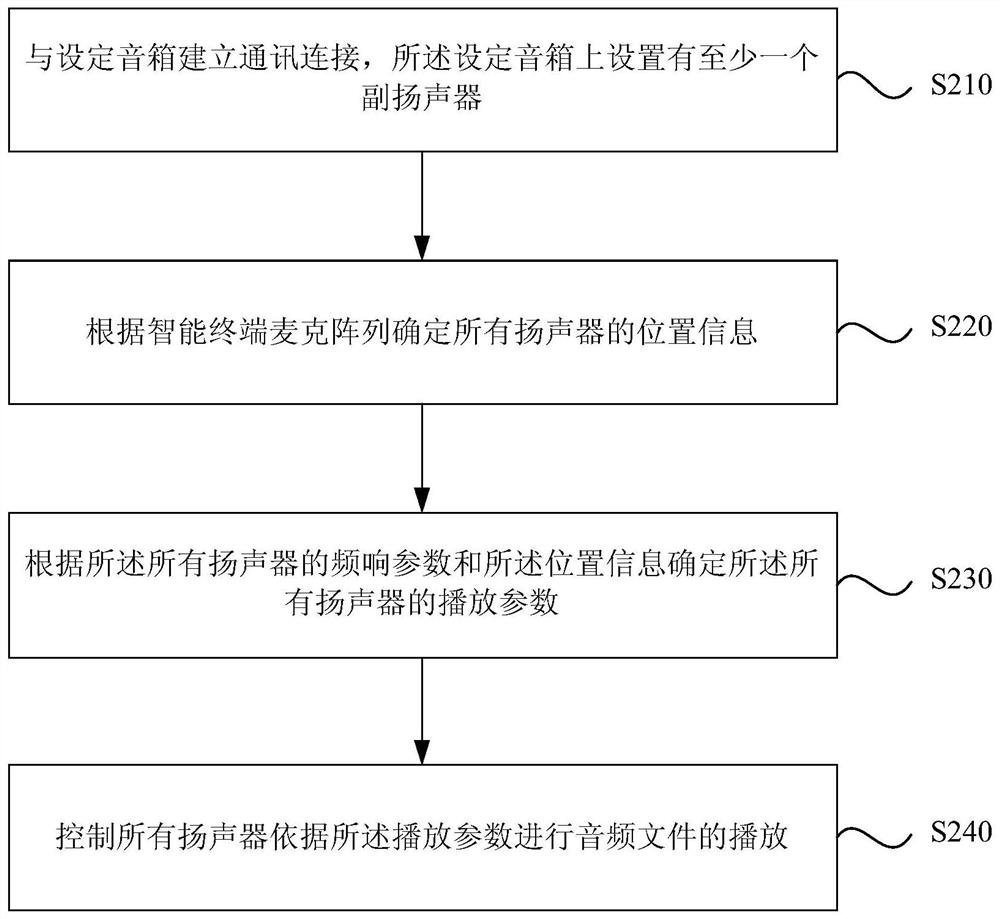

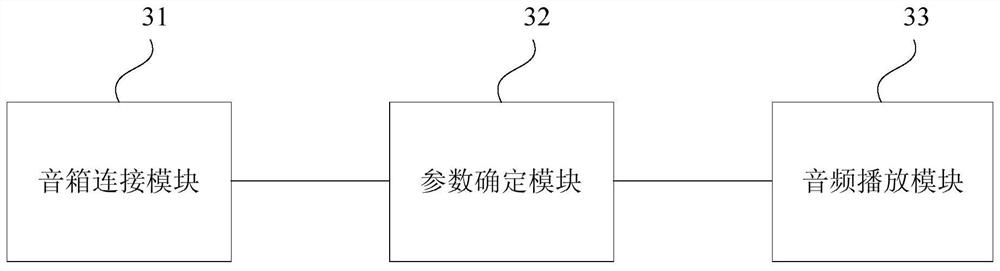

Audio playing method and device

ActiveCN106792365AImprove experienceTo achieve a three-dimensional effectSignal processingLoudspeaker signals distributionLoudspeakerComputer science

The invention discloses an audio playing method and device. The method comprises the steps of establishing communication connection with a set loudspeaker box, wherein the set loudspeaker box is equipped with at least one secondary loudspeaker; determining playing parameters of all loudspeakers according to the frequency response parameter of the at least one secondary loudspeaker and the frequency response parameter of a master loudspeaker arranged on a smart terminal, wherein the playing parameters comprise playing time and playing volume; and controlling all loudspeakers to play an audio file according to the playing parameters. According to the technical scheme provided by the embodiment of the invention, the problem that in the prior art, the smart terminal cannot play the audio file according to a three-dimensional effect through an internal loudspeaker or a single external loudspeaker is solved.

Owner:GUANGDONG XIAOTIANCAI TECH CO LTD

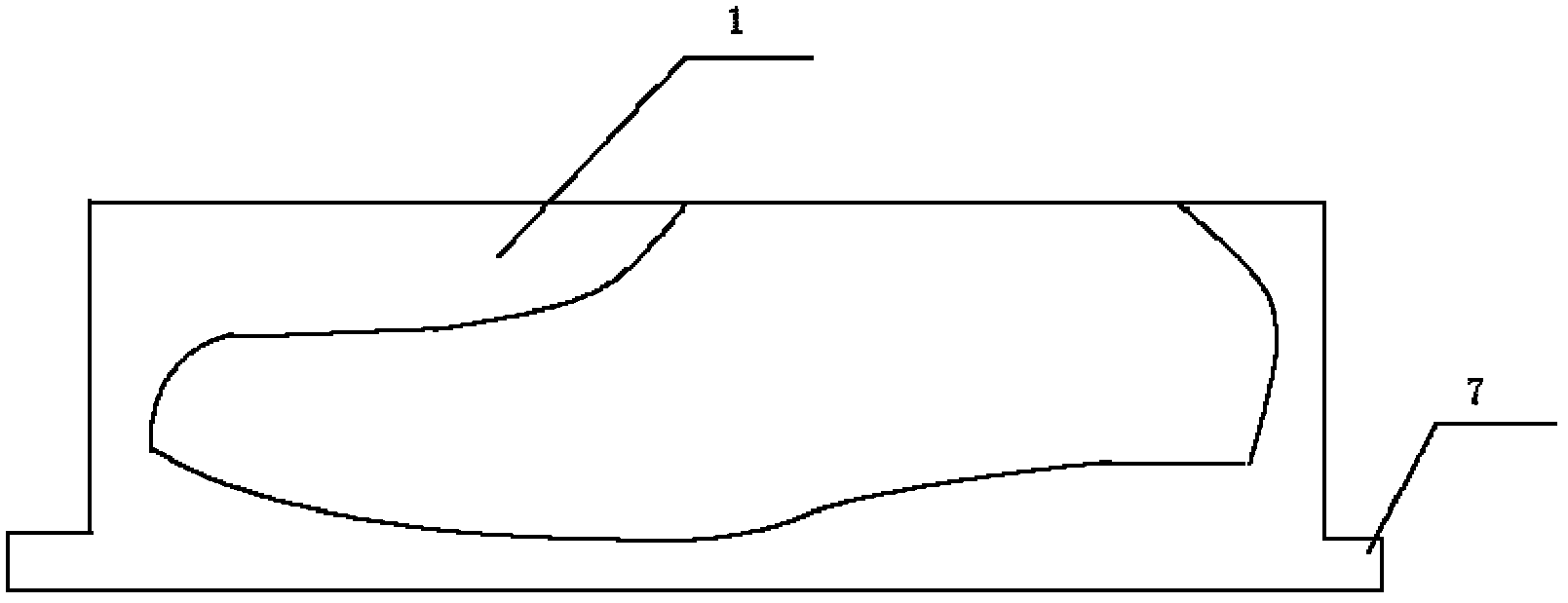

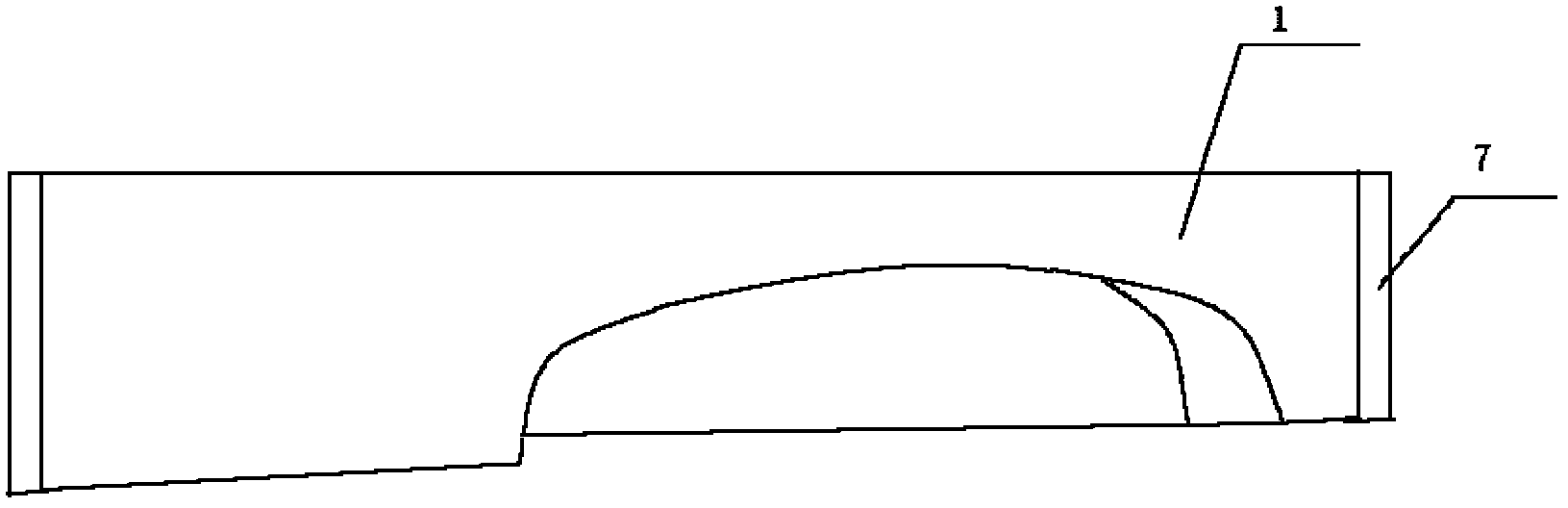

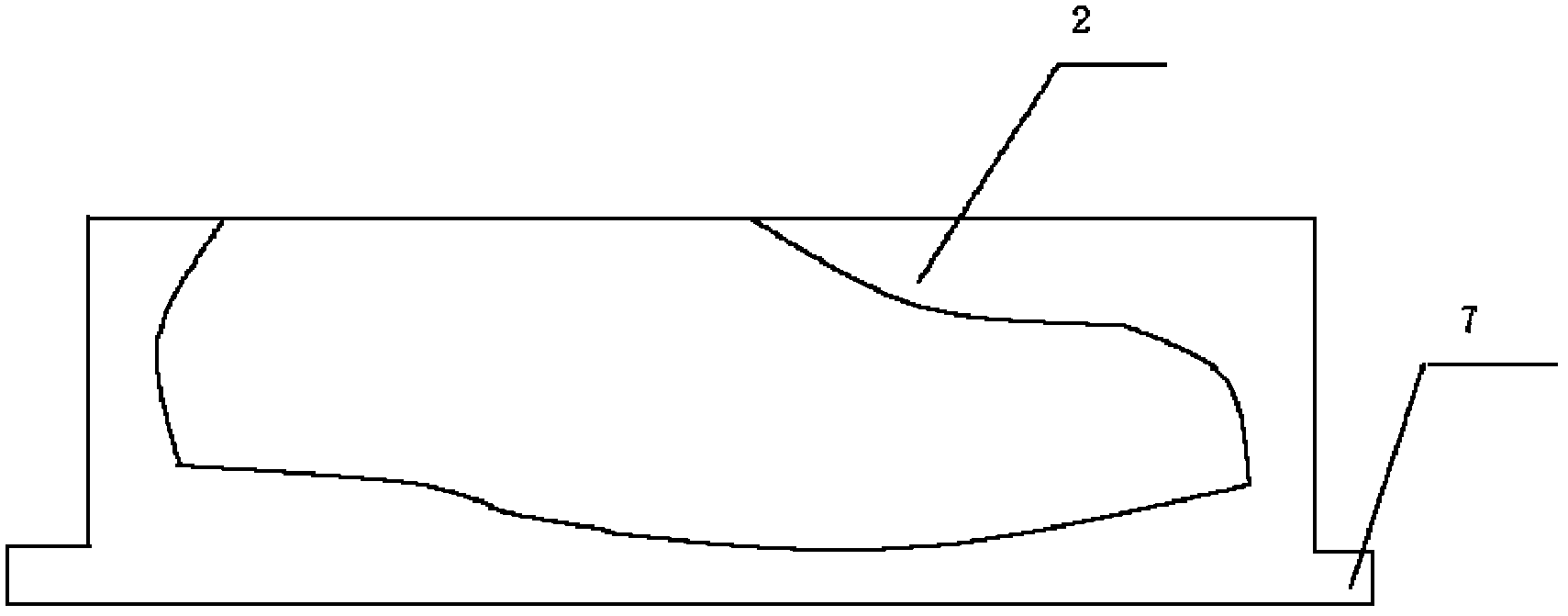

Tool and method for manufacturing foot mould

InactiveCN102601847AEasy to assembleEasy to measureCeramic shaping apparatusFoot typeUser satisfaction

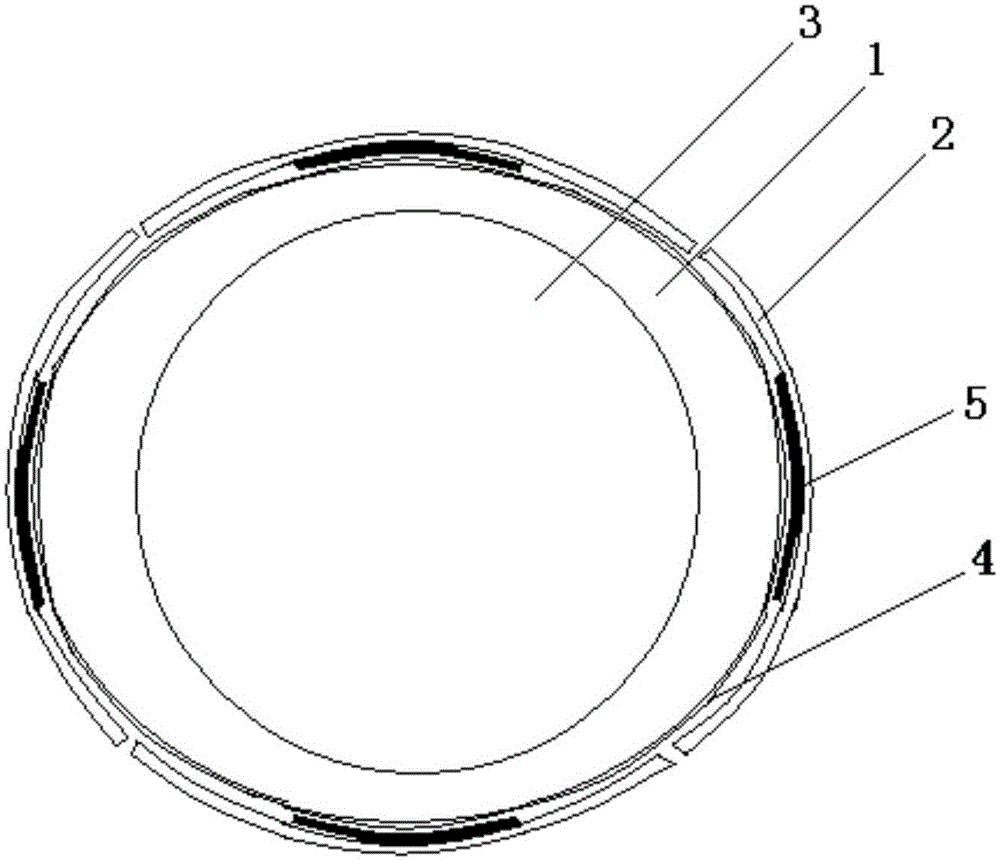

The invention relates to a tool for manufacturing a foot mould, which is characterized in that the tool comprises a first mould (3) and a second mould (4), wherein the first mould (3) comprises a first cavity (1) and a second cavity (2), the second mould (4) comprises a third cavity (5) and a fourth cavity (6), and each of the first mould (3) and the second mould (4) is in a foot sole similar shape. Simultaneously, the invention further provides a method for manufacturing the foot mould by applying the tool for manufacturing the foot mould. The tool for manufacturing the foot mould is simple in assembly, simple and convenient in measurement method and capable of manufacturing one exclusive personal foot mould for a user according to the foot shape of the user, and further an exclusive shoe last for the user can be manufactured, and hand-made customized shoes consistent with the size of the feet of the user and human engineering can be manufactured, so that user satisfaction is improved.

Owner:WENZHOU HEYUAN SHOES

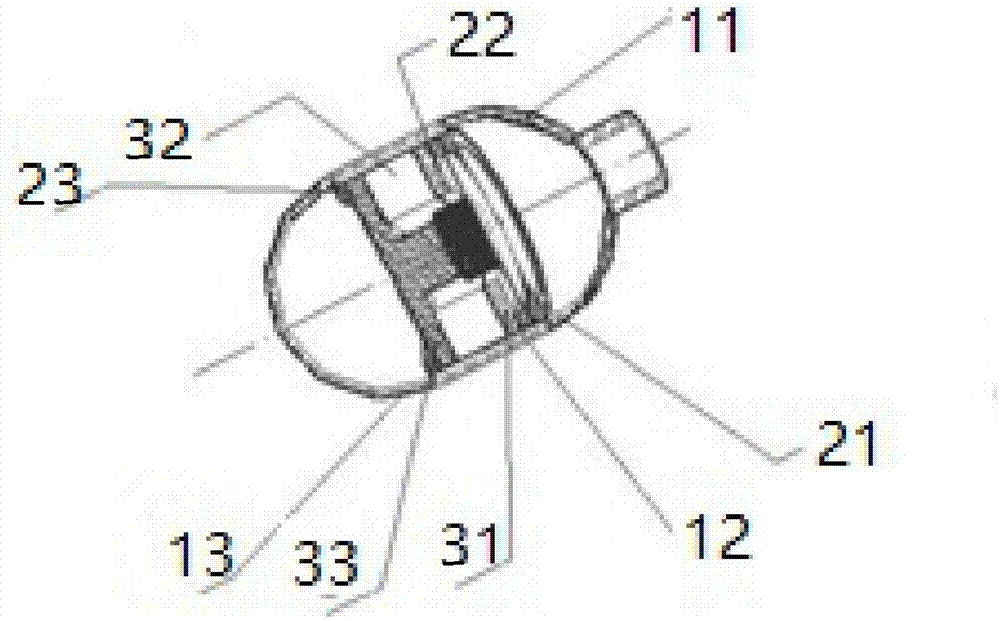

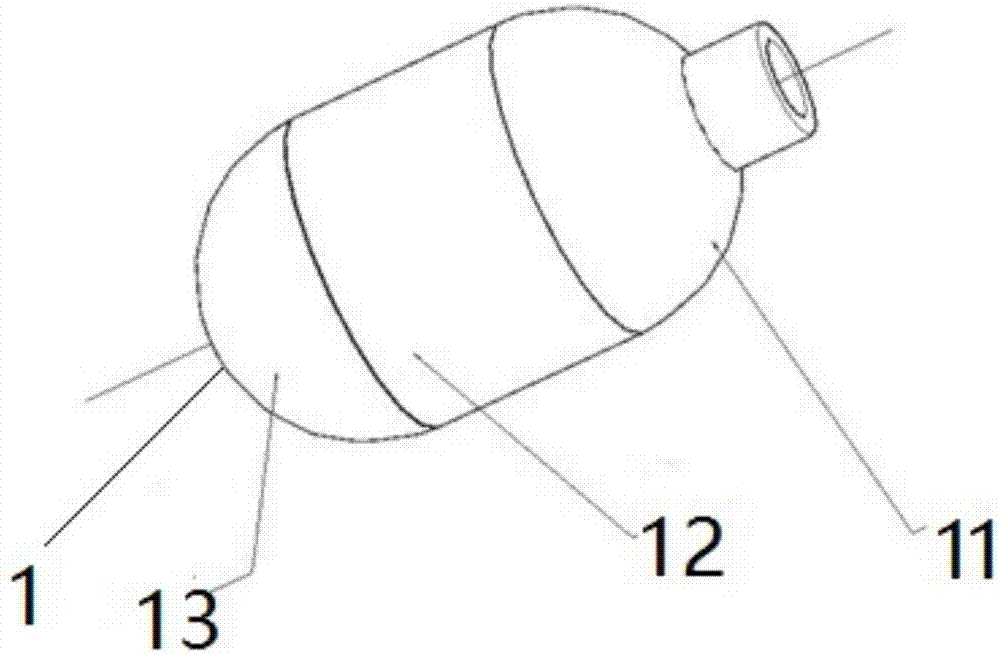

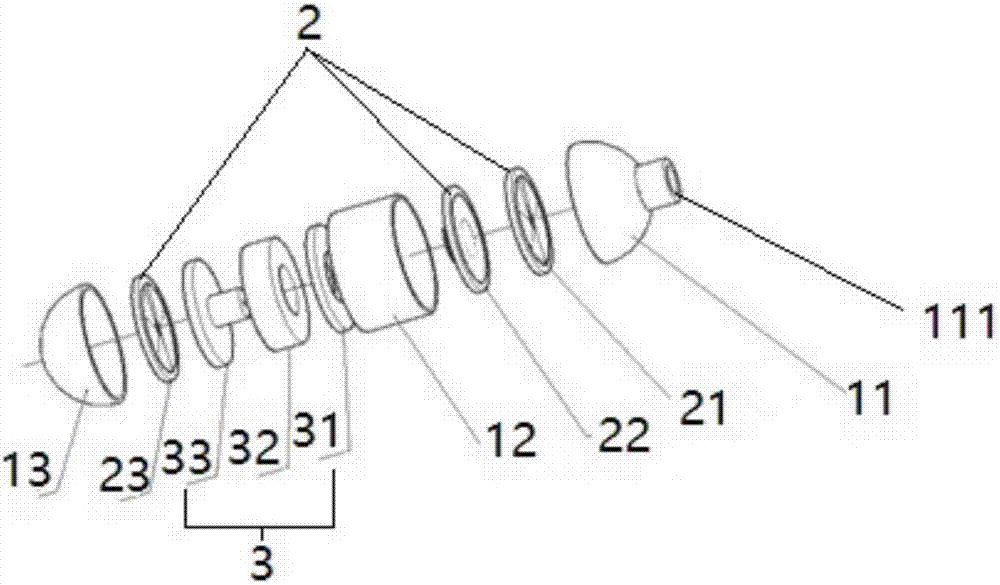

Horn with acoustic cavity

ActiveCN107277713AThe phase direction is clear and the thickness is clearThe phase direction is clear, the thickness is clear, the thickness is clearElectrical transducersLoudspeakersNoiseEngineering

The invention discloses a horn with an acoustic cavity, relates to the technical field of electronic products and solves the problems that through the unique cavity structure design, a first 180-degree cavity and a second 180-degree cavity form a 360-degree space, the 360-degree space infinitely extends outwards from a central point to generate a 360-degree spatial sound sense, and a 3D stereoscopic space is really realized, so that a music source is clear, strong and definite in each phase position direction, and through the unique material and structure of two damping membranes, the noise and the reflection sound which are generated by a second vibrating diaphragm are eliminated to realize a noise reduction effect. The main technical scheme of the invention is as follows: the horn comprises a shell, a vibrating diaphragm component and a magnetic circuit driving component, wherein the shell comprises a first cavity, a second cavity and a third cavity, wherein the first cavity, the second cavity and the third cavity are connected in sequence; a vibrating diaphragm component comprises a first vibrating diaphragm arranged in a first cavity, a second vibrating diaphragm arranged in a second cavity and a third vibrating diaphragm arranged in a third cavity; and a magnetic circuit driving component is arranged in the second cavity and comprises a magnetic conducting plate, a magnet and a T iron. The horn is mainly used for the electronic products.

Owner:深圳市金宏翔声学有限公司

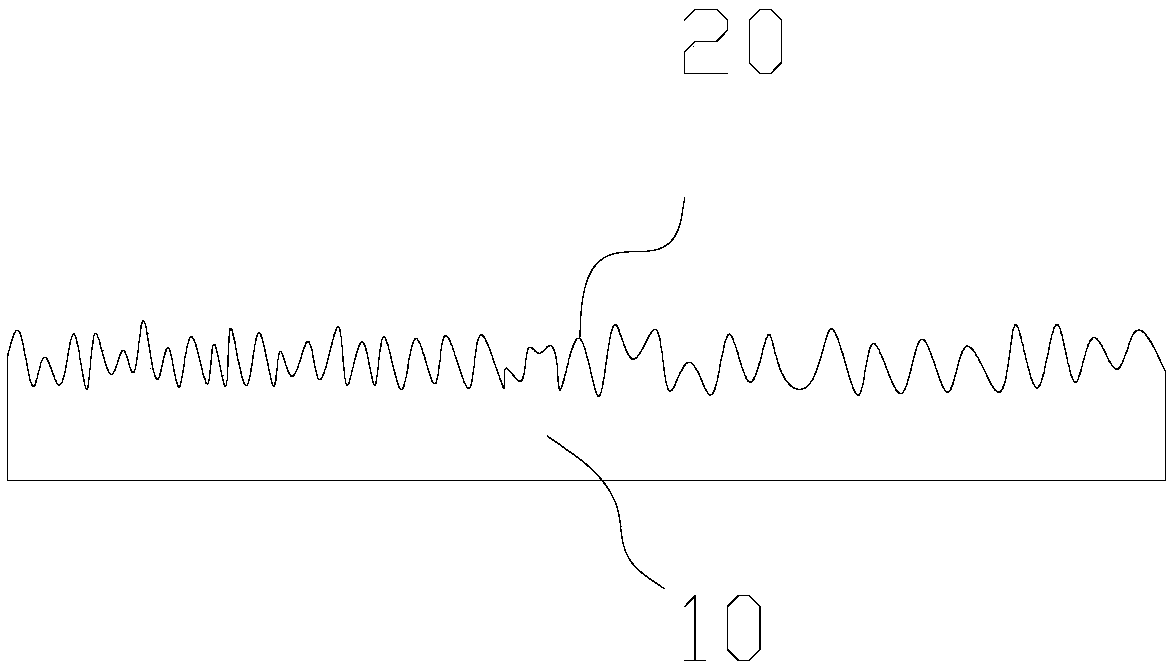

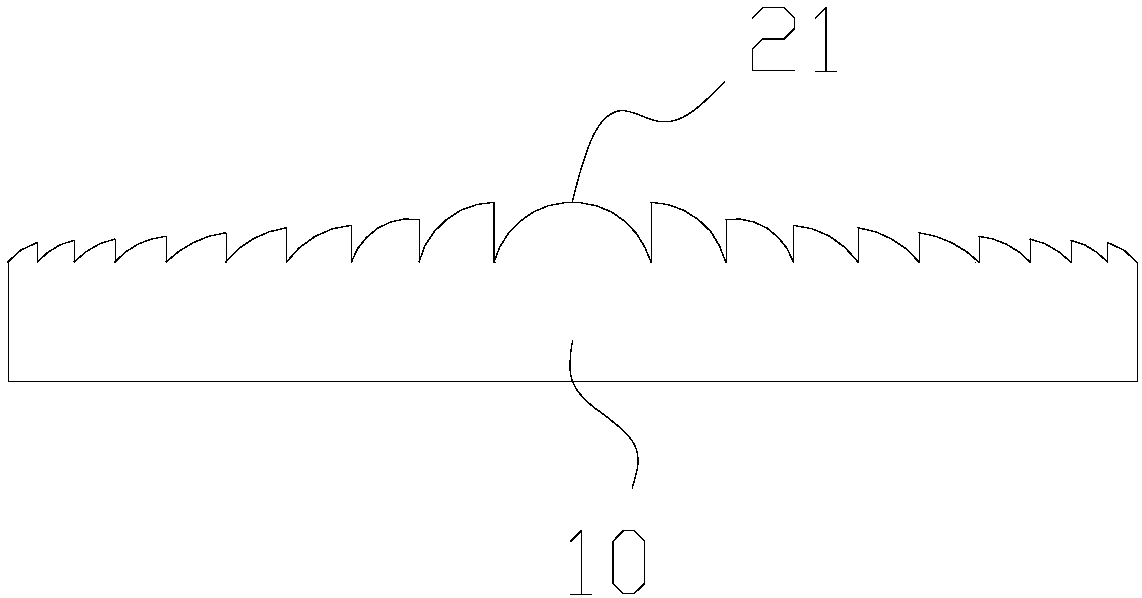

Three-dimensional sweater knitted structure and knitting method thereof

ActiveCN106480592ATo achieve a three-dimensional effectSave raw materialsWeft knittingTextile/flexible product manufactureEngineeringRaw material

Owner:湖州汉和制衣有限公司

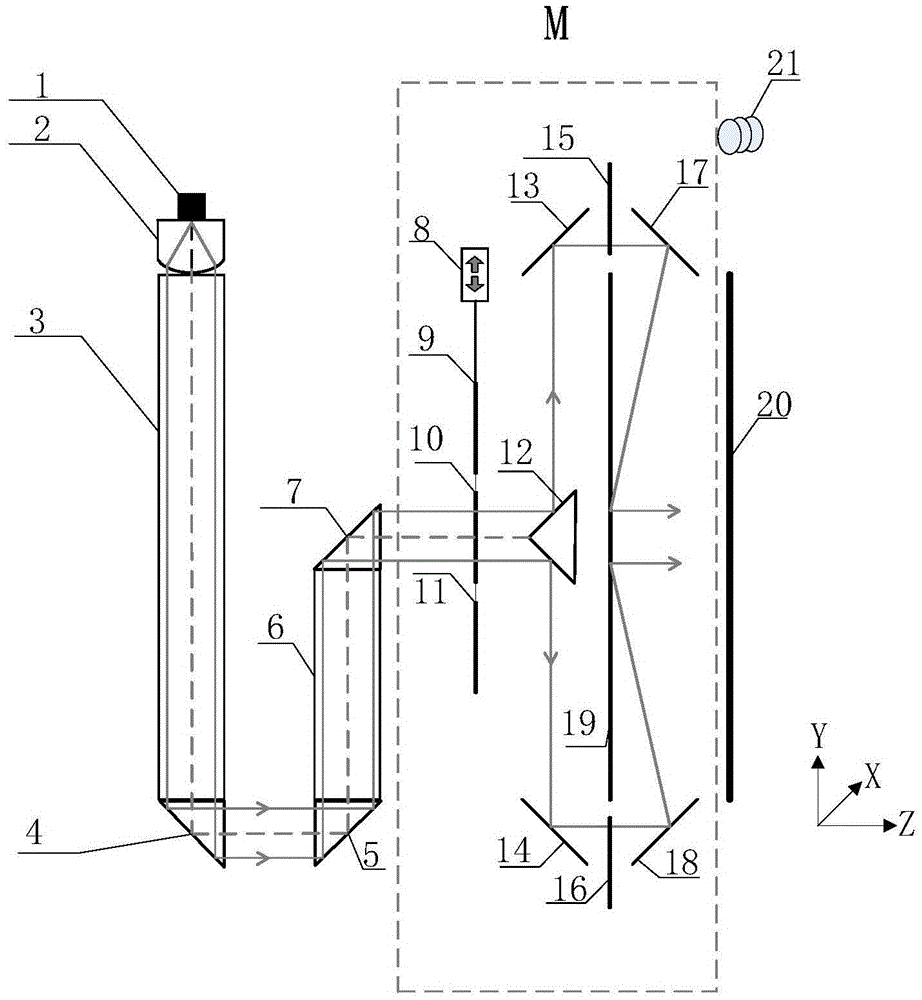

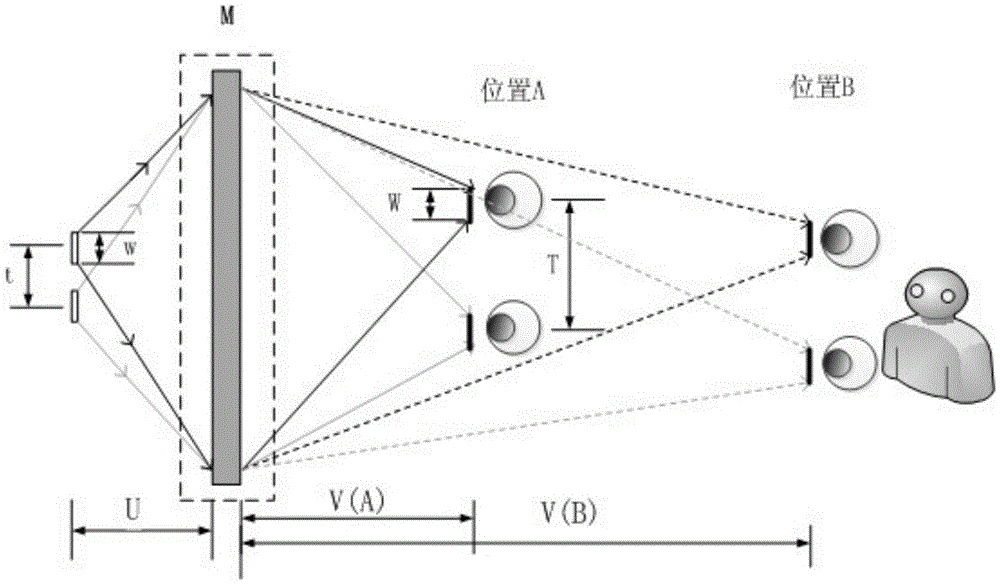

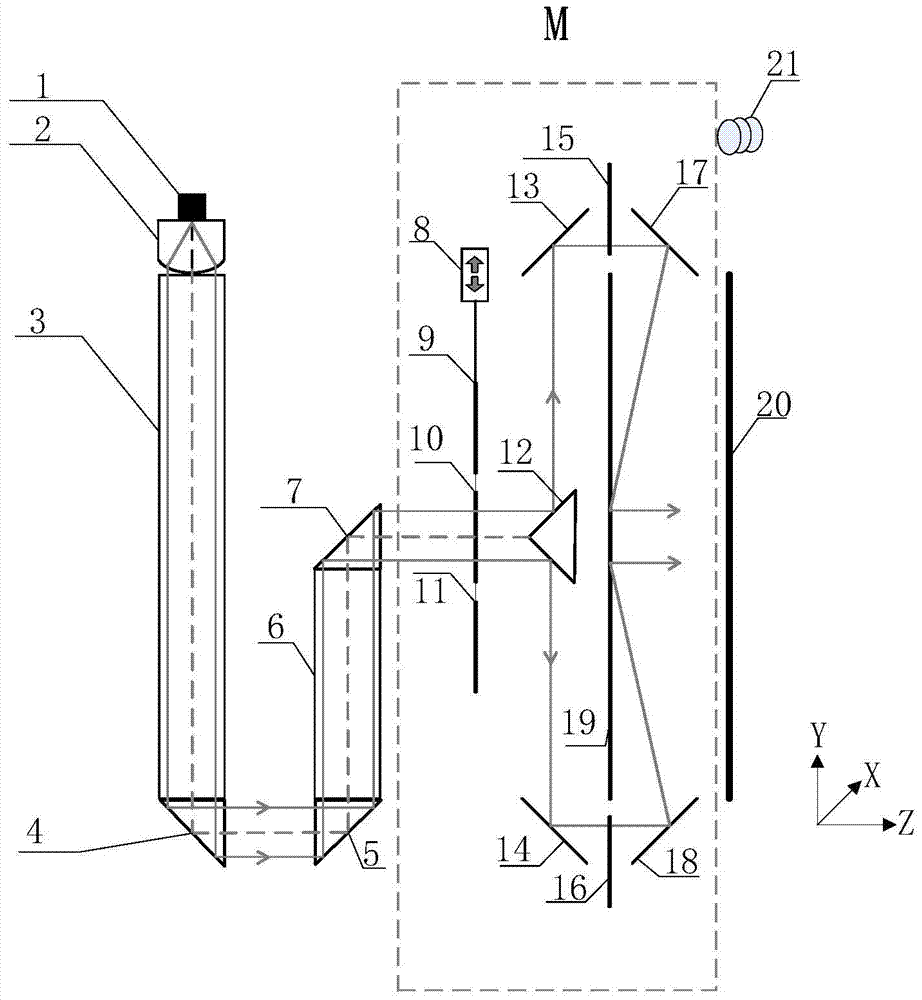

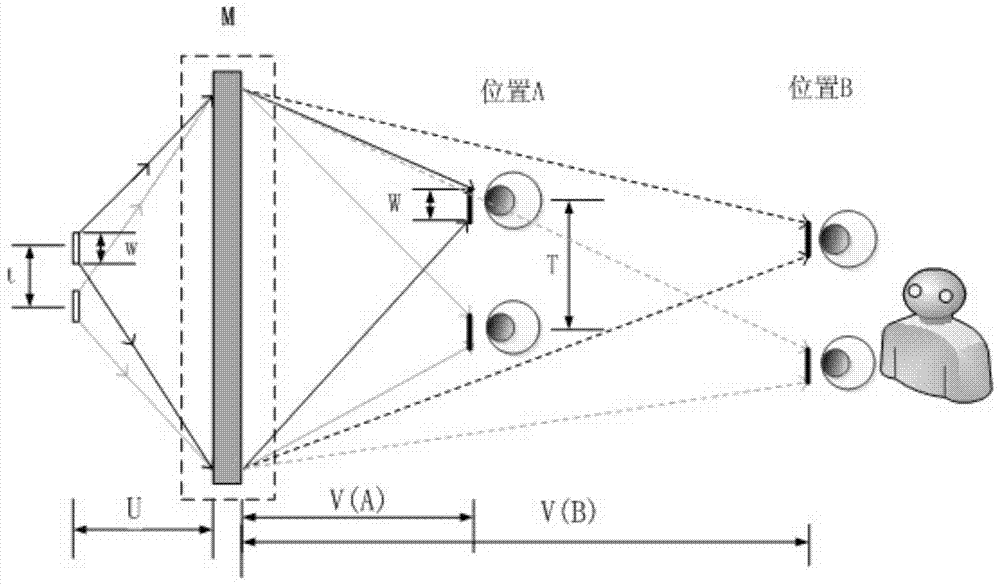

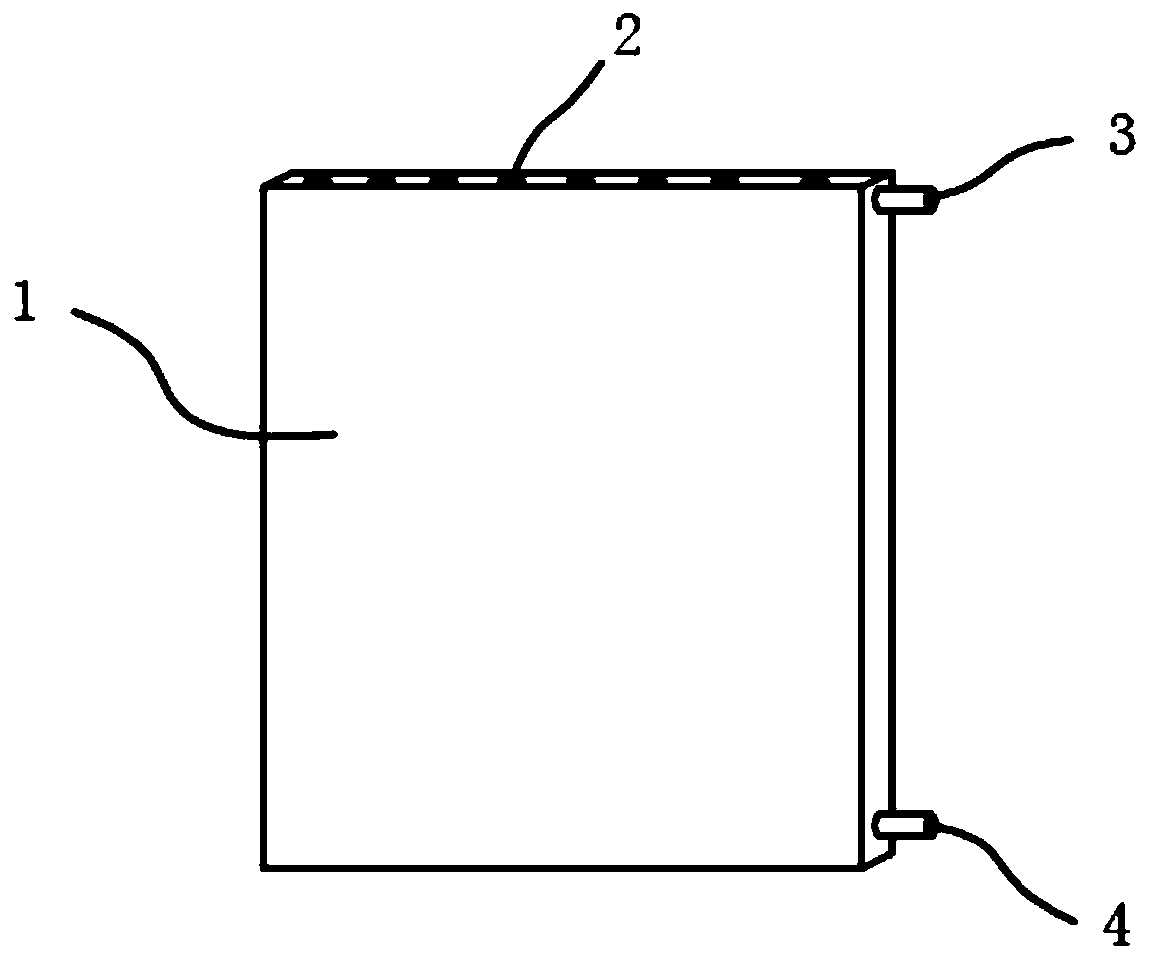

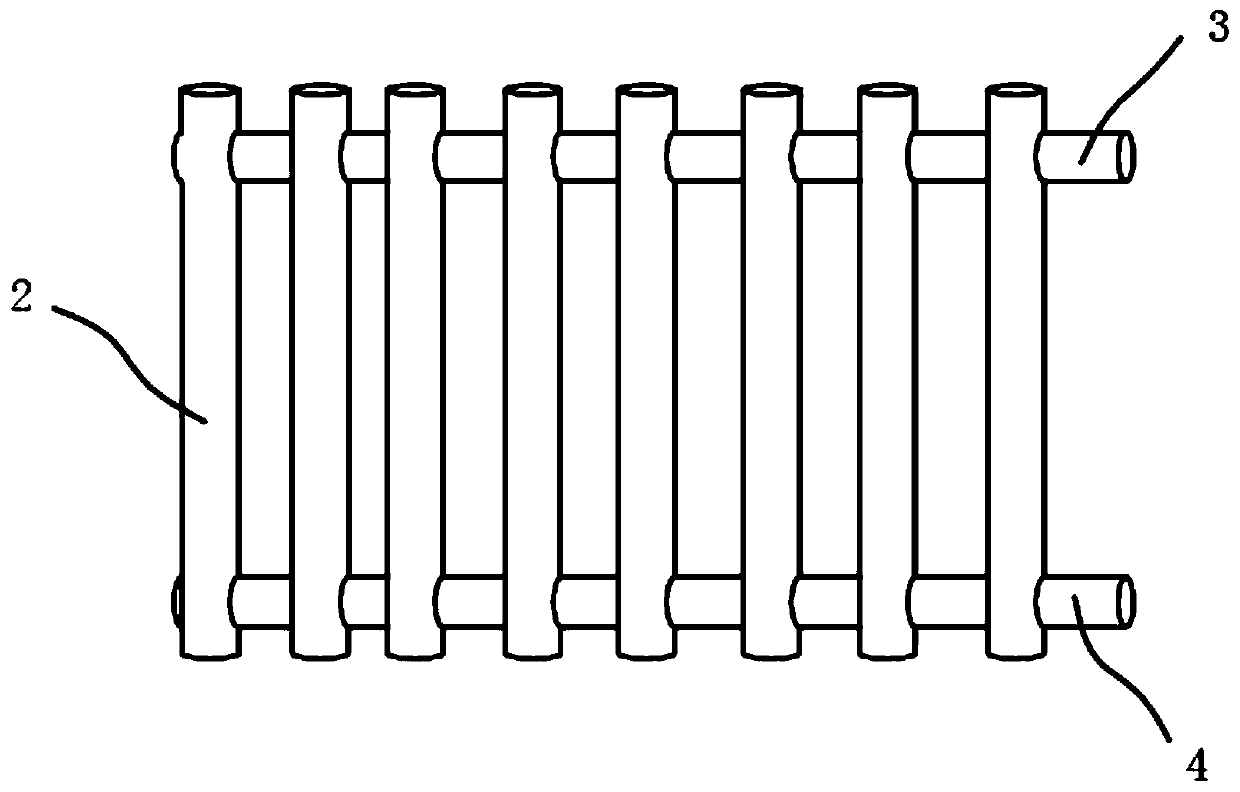

Stereopsis check method and device adopting symmetrical adjustable backlight structure

ActiveCN105049833AEnhanced backlight uniformity and brightnessGood image qualitySteroscopic systemsOptical elementsTriangular prismLight guide

A stereopsis check device adopting a symmetrical adjustable backlight structure comprises a symmetrical adjustable backlight device, a pupil position tracking module, a synchronization signal extraction module, a signal processing module and an image display screen. The symmetrical adjustable backlight device comprises a symmetrical adjustable optical component and an addressable light source component. The symmetrical adjustable optical component comprises a light guide module and a symmetrical adjustable imaging module. The light guide module comprises a collecting lens, a light guide device and a triangular prism. The symmetrical adjustable imaging module (M) comprises a lens, a lens switching device, an enoscope, a spectroscope and a refraction reflector. The signal processing module controls the addressable light source component in the adjustable backlight structure according to received pupil position information and a video synchronization signal. While a left image is displayed, the signal processing module lightens a corresponding luminescent unit according to left eye pupil position information, so that the light is converged at the left eye pupil. While a right image is displayed, the signal processing module lightens a corresponding luminescent unit according to right eye pupil position information, so that the light is converged at the right eye pupil.

Owner:NANJING UNIV

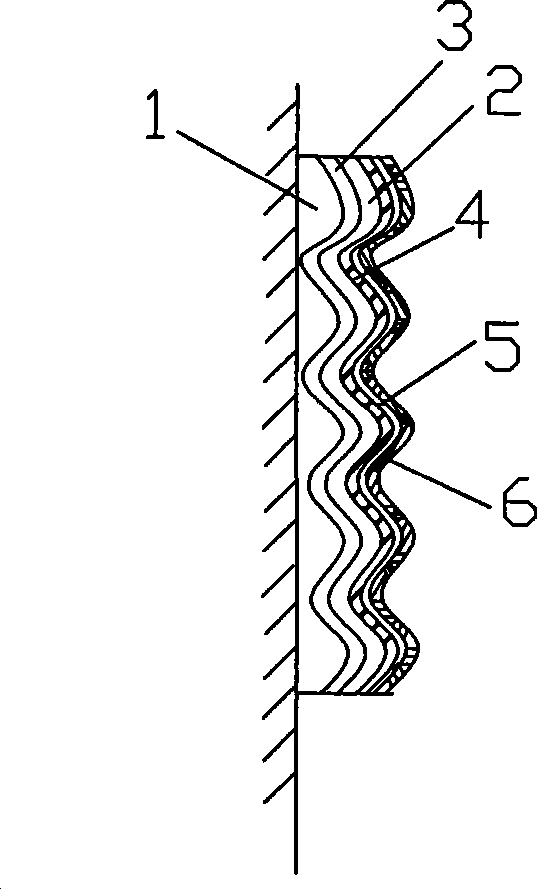

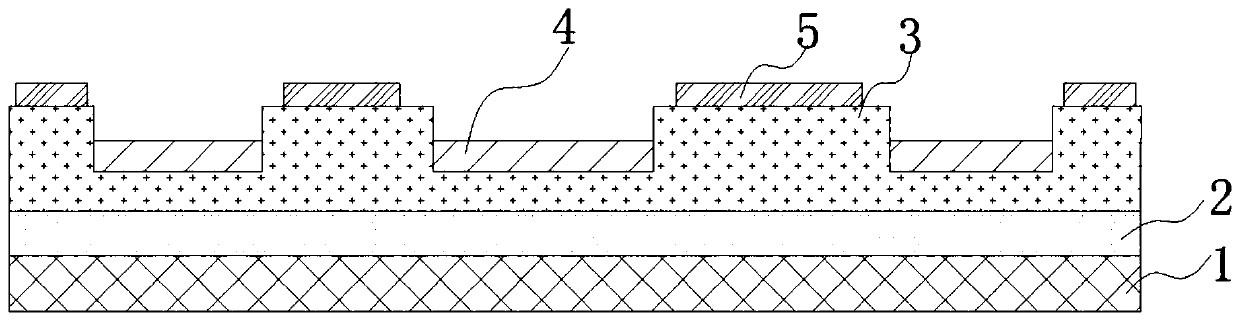

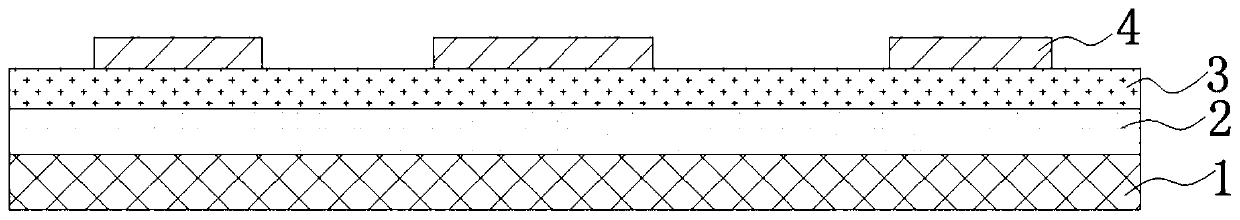

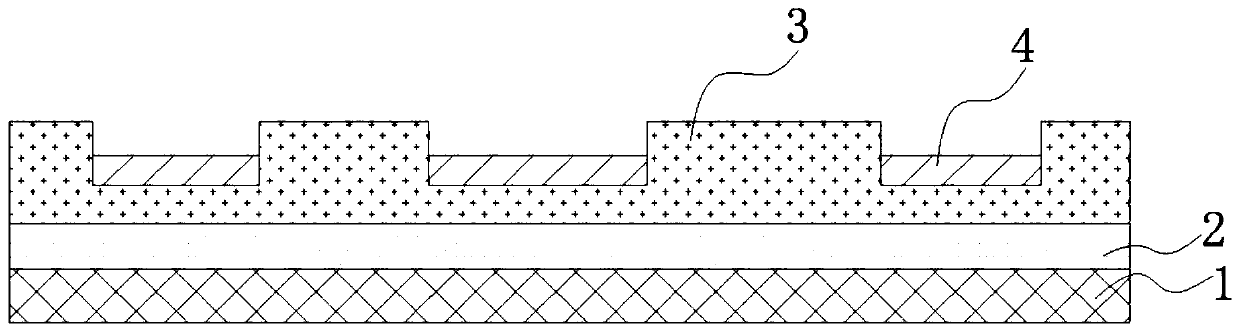

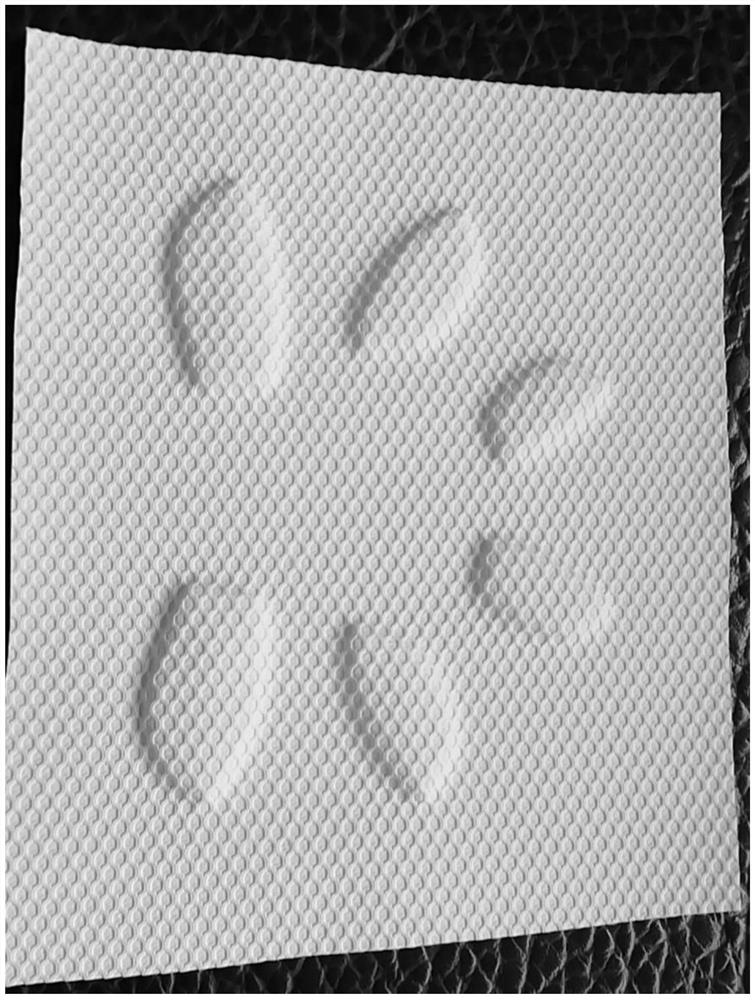

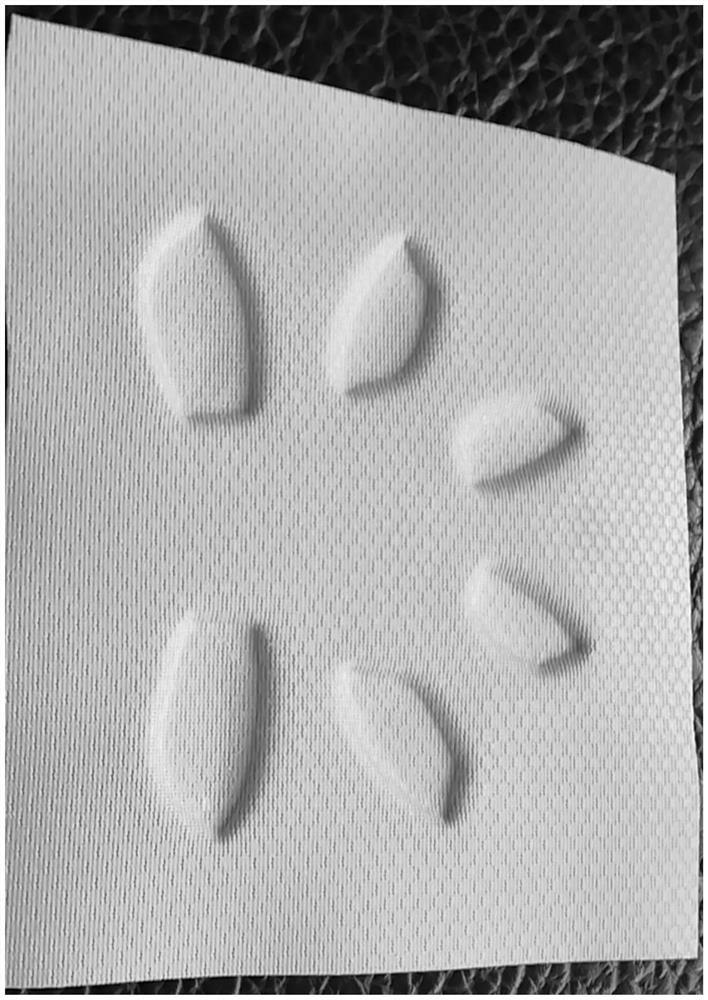

Three-dimensional wallpaper and production method thereof

PendingCN111119424AFull of variabilityDesigned for easy handlingCovering/liningsPattern printingSlurryCoating

The invention provides three-dimensional wallpaper and a production method thereof. The three-dimensional wallpaper comprises a base material layer, a bottom coating, a foaming slurry layer, a foaminginhibiting slurry layer and an ink layer; the bottom coating is compounded on the base material layer; the foaming slurry layer is compounded on the bottom coating and comprises a concave face and aconvex face; the foaming inhibiting slurry layer is compounded on the concave face; and the ink layer is compounded on the convex face and / or the foaming inhibiting slurry layer. According to the three-dimensional wallpaper, the foaming slurry layer and the foaming inhibiting slurry layer are combined to achieve the three-dimensional effect; the grains and shapes of textures are decided by the foaming slurry layer and the foaming inhibiting slurry layer jointly and change along with the applied position of the foaming inhibiting slurry layer on the foaming slurry layer and the thickness of thefoaming inhibiting slurry layer, special textures and patterns can be formed on the surface of the wallpaper, the textures are diverse and beautiful and are full of variability, grain design is easier to control, and a wallpaper product with more colorful patterns can be made; and meanwhile, the production method has the advantages of being free of size limitation and batch limitation, low in cost and high in preparation efficiency.

Owner:GUANGDONG YULAN GRP

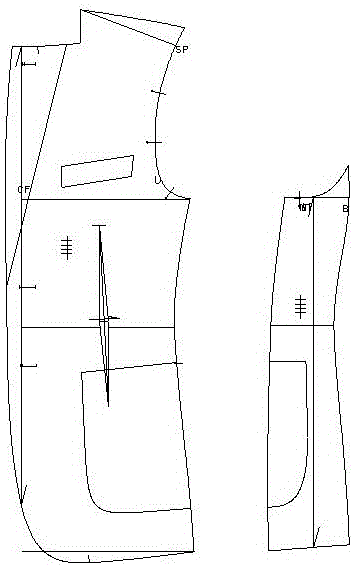

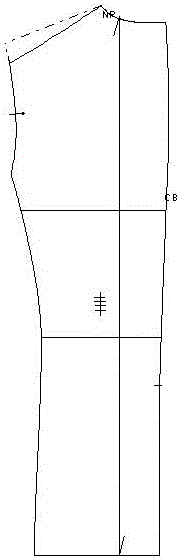

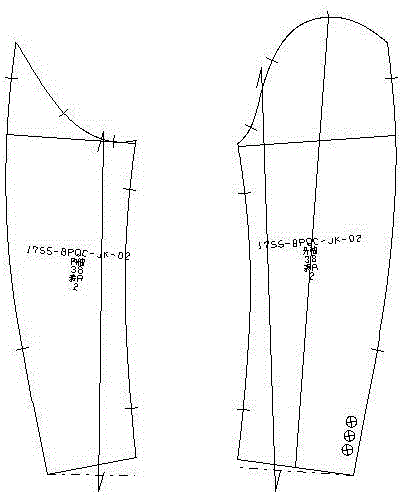

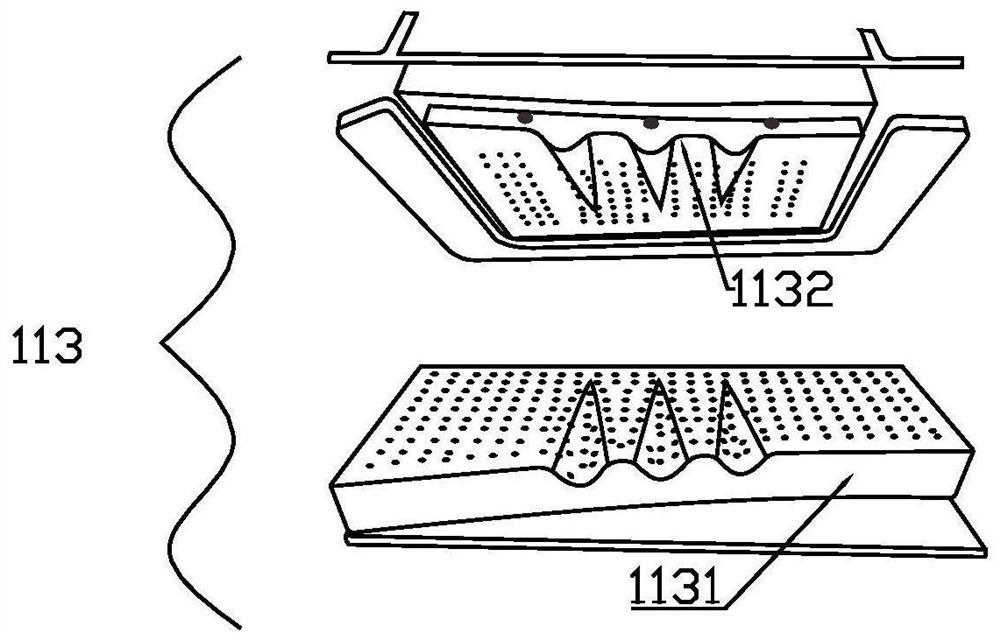

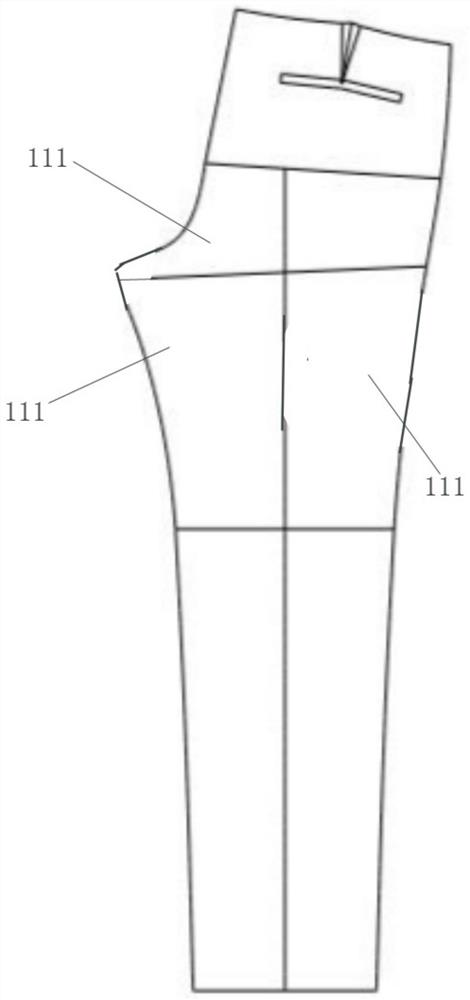

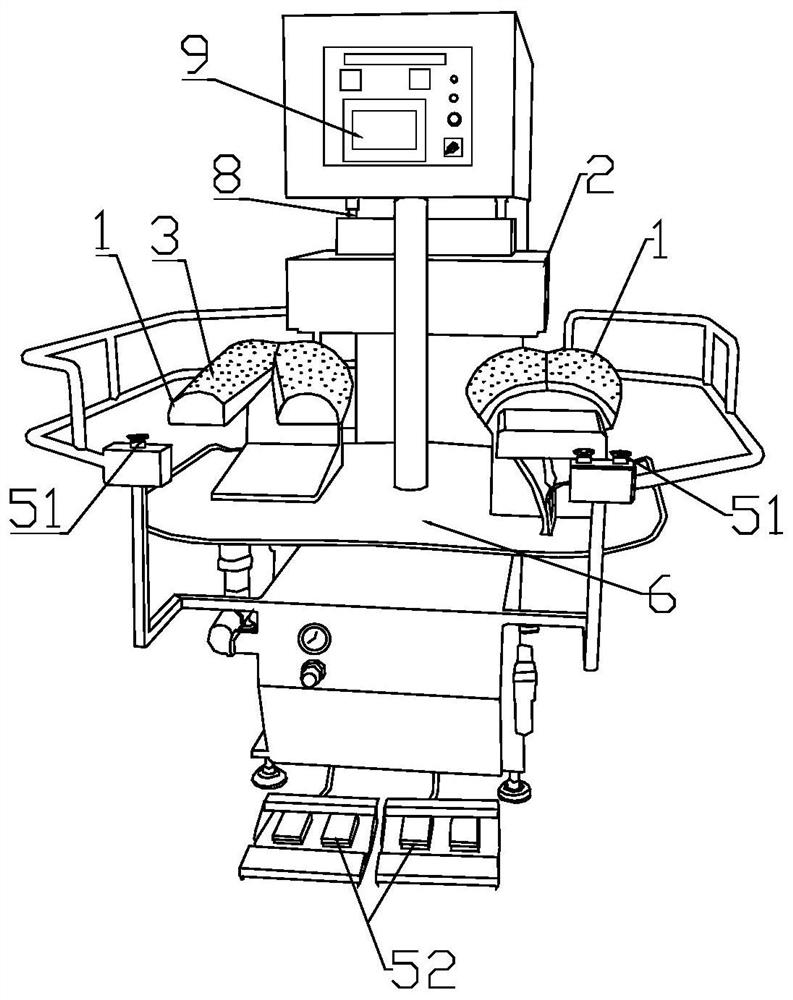

Crotch three-dimensional shaping processing method

PendingCN111876955AEffective stereotypesFast shapingTextile treatment with treating outlet contectShaping/stretching tubular fabricsButtocksMechanical engineering

The invention discloses a crotch three-dimensional shaping machine and a crotch three-dimensional shaping processing method. The crotch three-dimensional shaping processing method is characterized bycomprising the following steps that S1, cloth is prepared, and the cloth is loosened before cloth cutting to enable the cloth to retract for 24 hours; S2, cutting is carried out according to the required size, and the cloth is cut into trouser forming sheets, wherein two front panels and two rear panels are arranged; S3, buttock positions of the two back panels are set as a back rise position, andhigh-temperature shaping and drawing are carried out on the inner side and the outer side of a back rise to form a preset shape; S4, sewing, front and rear bag assembling, zipper assembling, waistband making, local bar-tack fixing, and button hole opening are carried out to form a trouser finished product; S5, the finished product is washed with water, and ironed; and S6, finally, high-temperature positioning and shaping are carried out on a crotch and buttocks. The processing technology is simple, the buttocks and the crotch of a trouser are shaped, and the complete three-dimensional effectis achieved.

Owner:广州德贤服装有限公司

Three-dimensional jigsaw based on cloth jigsaw pieces

InactiveCN105056519ATo achieve a three-dimensional effectSimple structureIndoor gamesEngineeringShock resistance

The invention discloses a three-dimensional jigsaw based on cloth jigsaw pieces. The three-dimensional jigsaw based on the cloth jigsaw pieces comprises a three-dimensional jigsaw bottom template and multiple cloth jigsaw pieces which can be spliced on the outer surface of the three-dimensional jigsaw bottom template; the cloth jigsaw pieces are spliced with the three-dimensional jigsaw bottom template through connecting pieces; the outer surface of the three-dimensional jigsaw bottom template is provided with grooves, and the bottom faces of the cloth jigsaw pieces are provided with convex blocks matched with the grooves; the quantity of the grooves is the same as that of the cloth jigsaw pieces, and the forming positions of the grooves are positioned according to blocking partition of jigsaw patterns. The three-dimensional jigsaw based on the cloth jigsaw pieces is compact in structure, convenient to disassemble and assemble, easy to manufacture, safe, reliable and high in practicability; the three-dimensional effect is achieved, the product structure is greatly enriched, and jigsaw objects are not limited to plane patterns any more but any object shapes; the jigsaw operating process is single, the jigsaw pieces cannot be displaced any more, the shock resistance is high, and a temporarily spliced semi-finished product cannot be influenced by moving; meanwhile, the three-dimensional jigsaw based on the cloth jigsaw pieces is convenient to store, not prone to being lost or damaged and long in service life.

Owner:张家港市华益纺织有限公司

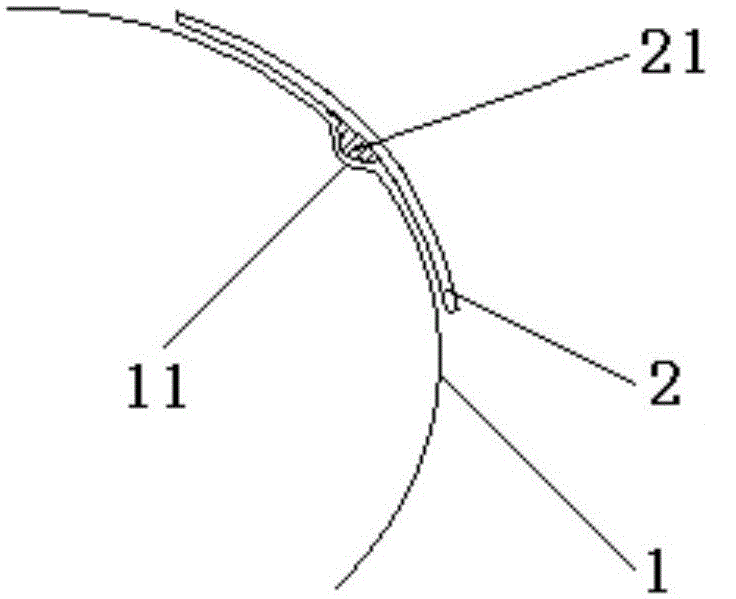

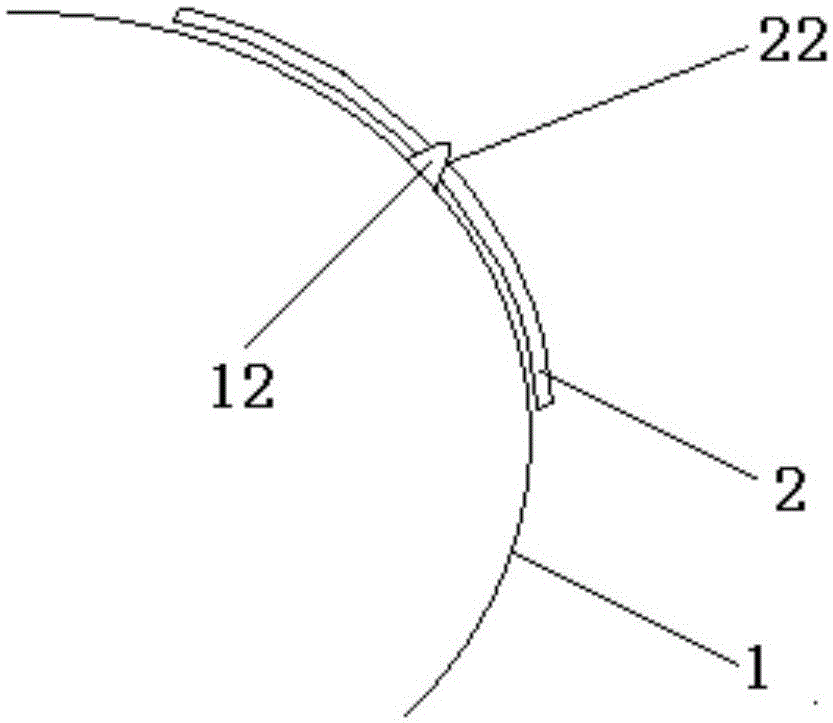

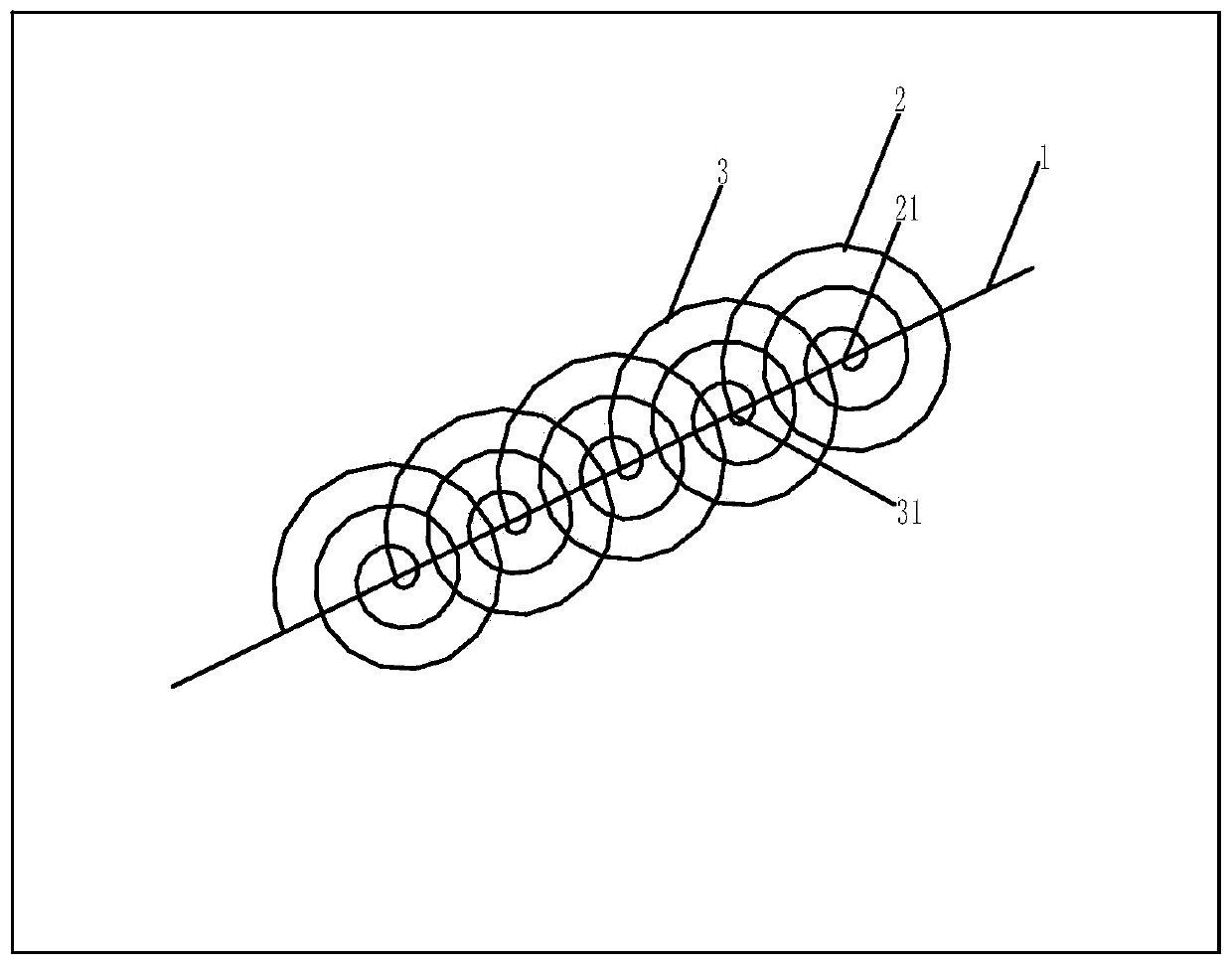

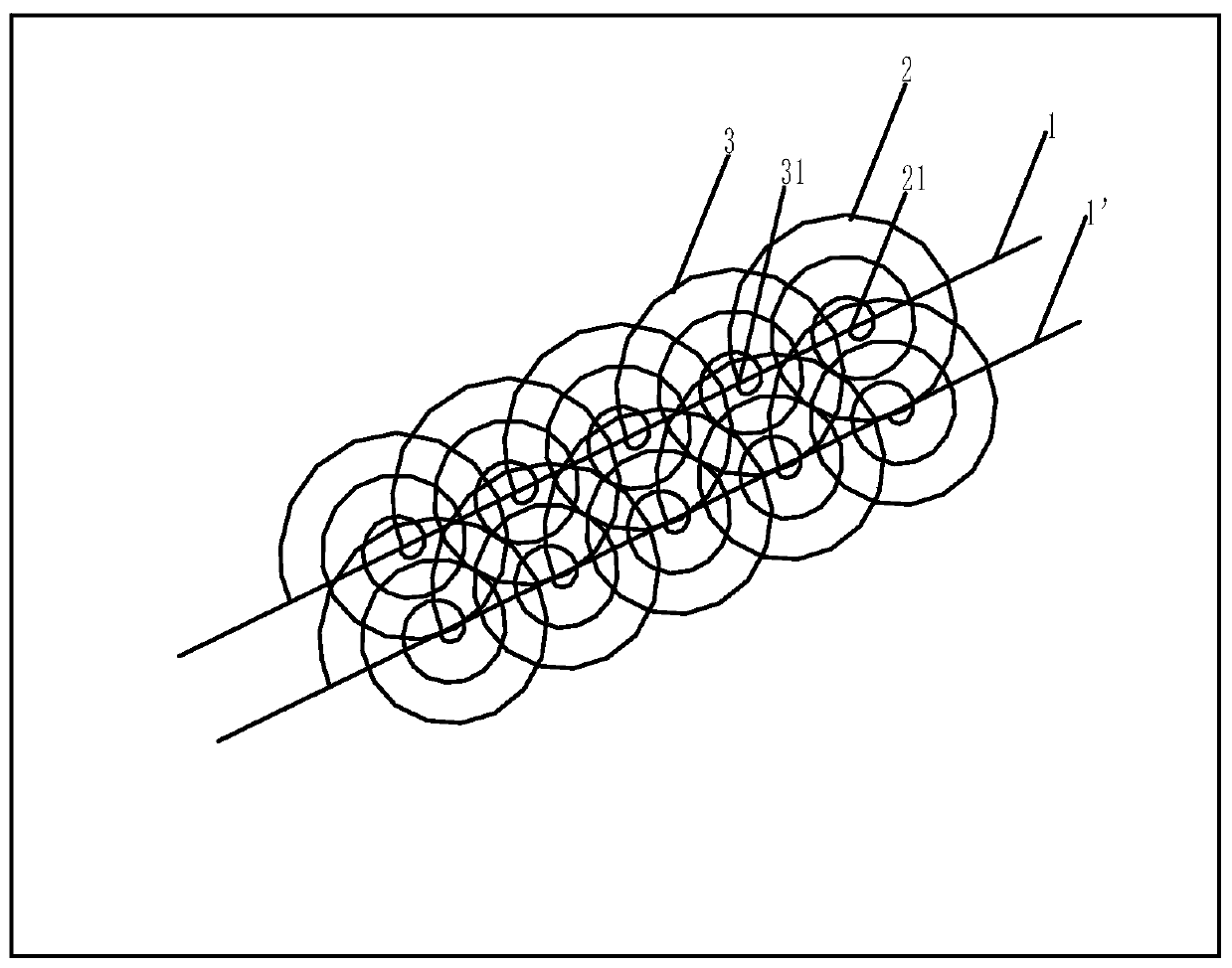

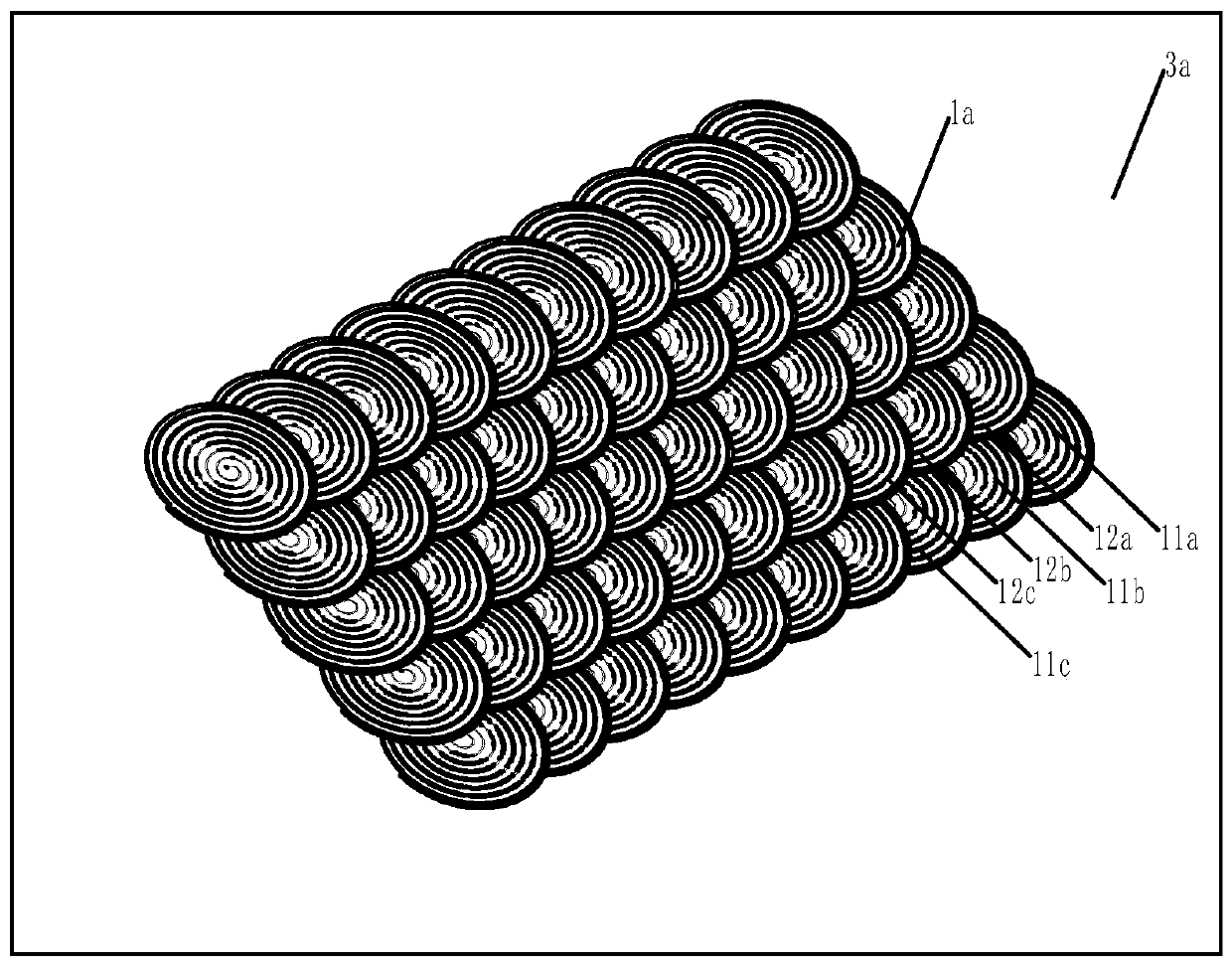

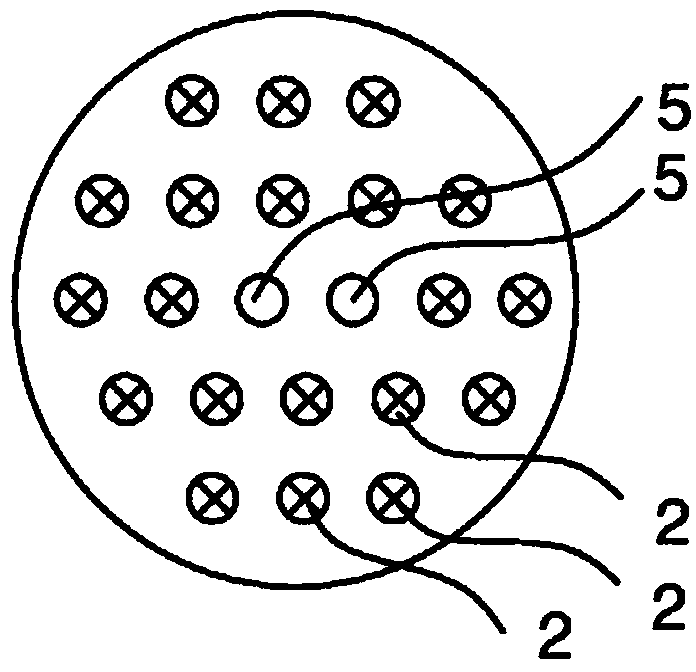

Computer embroidery disk ring close-packed stacking three-dimensional embroidery method and embroidery product

InactiveCN110004611AHigh degree of reductionVariety of aestheticsAutomatic machinesAdditional valuesEngineering

The invention belongs to the technical field of embroidery, and particularly relates to a computer embroidery disk ring close-packed stacking three-dimensional embroidery method and an embroidery product. The method includes the steps: making a plate by a computer, and designing a reference line on a fabric to be embroidered; making disk-shaped embroidery tracks with a plurality of spirals round the reference line from inside to outside or from outside to inside by taking the reference line as an axis to form a second disk shape; forming disk-shaped embroidery tracks of a plurality of three-dimensional stacking layers taking a first reference line as an axis, and so on. According to the computer embroidery method, three-dimensional effects are achieved by making the plate by the computer,the embroidery product has high reduction degree of hand embroidery, rich in hand feeling, high in three-dimensional layer sense and rich, beautiful and diverse in pattern, and a mechanized and large-scale embroidery process with an improved additional value is achieved.

Owner:林淳爽

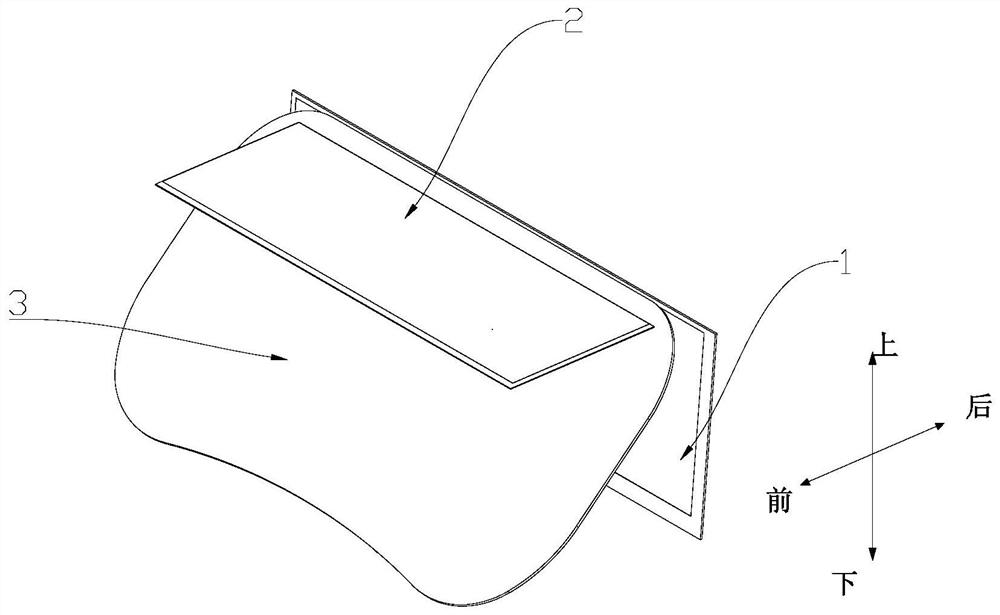

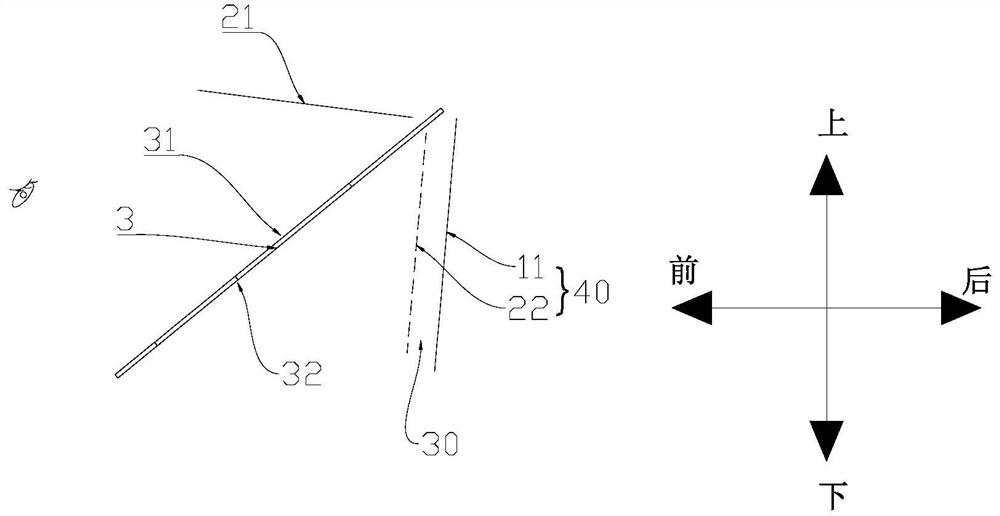

car dashboard

ActiveCN113799603BTo achieve a three-dimensional effectShow normalyInstrument arrangementsDashboardInformation control

The invention relates to an automobile instrument panel, which comprises a first segment code screen, a second segment code screen and a light processing board. The first segment code liquid crystal panel of the first segment code screen is provided with a first car image for displaying a trolley pattern group The controllable display area group, the second segment code liquid crystal panel of the second segment code screen is provided with a second car image controllable display area group for displaying the car pattern group, and the car instrument panel also includes a control unit. The input information or feedback information controls the display of at most one of the first vehicle image controllable display area group and the second vehicle image controllable display area group. The car instrument panel involved in the present invention can achieve a three-dimensional display effect; in addition, both the first segment code screen and the second segment code screen can be used to display the car pattern group, thereby ensuring the controllable display area of the car image on one of the segment code screens When the car image controllable display area group of another segment code screen is illuminated when the group cannot be normally lit, it is ensured that the car dashboard can normally display the car pattern group.

Owner:HEILONGJIANG TIANYOUWEI ELECTRONICS CO LTD

A main body printing process of mobile phone glass

InactiveCN103395309BAvoid it happening againPerspective has no effectOther printing apparatusScreen printingEngineering

The present invention relates to the technical field of mobile phone glass printing, in particular to a main body printing process of mobile phone glass, comprising the following steps: A, the first mirror silver printing: use screen printing technology to scrape mirror silver printing on the lower surface of the glass white sheet layer; B, the second blue-purple printing: scrape the second blue-purple printing layer on the lower surface of the glass white sheet using screen printing technology; C, the third pearlescent white printing: use Screen printing technology scrape the third pearl white printing layer. The present invention uses a composite printing process of the first mirror silver printing, the second blue-violet printing and the third pearl white printing on the glass white sheet, so that the printed pattern has a three-dimensional effect, and the transition between different ink layers is natural. The invention has the advantages of simple process, convenient operation and control, stable quality, high production efficiency and large-scale industrial production.

Owner:萍乡星弛光电科技有限公司

A composite printing process of mobile phone glass with 3D effect

InactiveCN103395310BAvoid it happening againPerspective has no effectOther printing apparatusTelephone set constructionsEtchingThin membrane

The invention relates to the technical field of mobile phone glass printing, in particular to a composite printing process for mobile phone glass with 3D effects, comprising the following steps: A. Vacuum coating: After cleaning the glass white sheet, put it into a vacuum coating machine, and apply it on the glass white The upper surface and the lower surface of the sheet are electroplated with a high refractive index material TiO2 thin film layer and a low refractive index material SiO2 thin film layer in turn; B, main body printing: take out the glass white sheet after vacuum coating, and carry out on the lower surface of the glass white sheet The main body is printed to obtain the pattern area; C. Chemical etching: perform chemical etching on the non-pattern area after the main body of the glass white sheet is printed, and clean the chemically etched glass white sheet; D. Cover printing: print on the glass white sheet The printed pattern area of the sheet body and the non-pattern area after chemical etching are covered and printed to obtain a mobile phone glass with a 3D effect. Through the above steps, the present invention can display 3D stereoscopic effects on the glass of the 2D mobile phone.

Owner:萍乡星弛光电科技有限公司

Method for manufacturing plastic identifier by adopting gold stamping and laser etching technology

ActiveCN101727774BGood adhesionReduce manufacturing costStampsDuplicating/marking methodsLaser etchingPolymer science

The invention discloses a method for manufacturing a plastic identifier by adopting gold stamping and laser etching technology. The method comprises the following steps: firstly, adopting a gold stamping film material with wiredrawing effect on injection molding products; processing by multi-face wiredrawing gold stamping technology to obtain the plastic products with strong metal luster and wiredrawing effect on the surface; and achieving an expected value of the laser etching depth of the product surface by adjusting laser etching technological parameters so as to realize the three-dimensional effect of imitated salient point printing on the surface of the products. Therefore, identification nameplates or other plastic products which have the advantages of clear patterns, beautiful appearance, garish color and good performance of high adhesion, wear resistance, weather resistance and the like are obtained, and further metal materials with high cost are replaced.

Owner:通达创智(厦门)股份有限公司

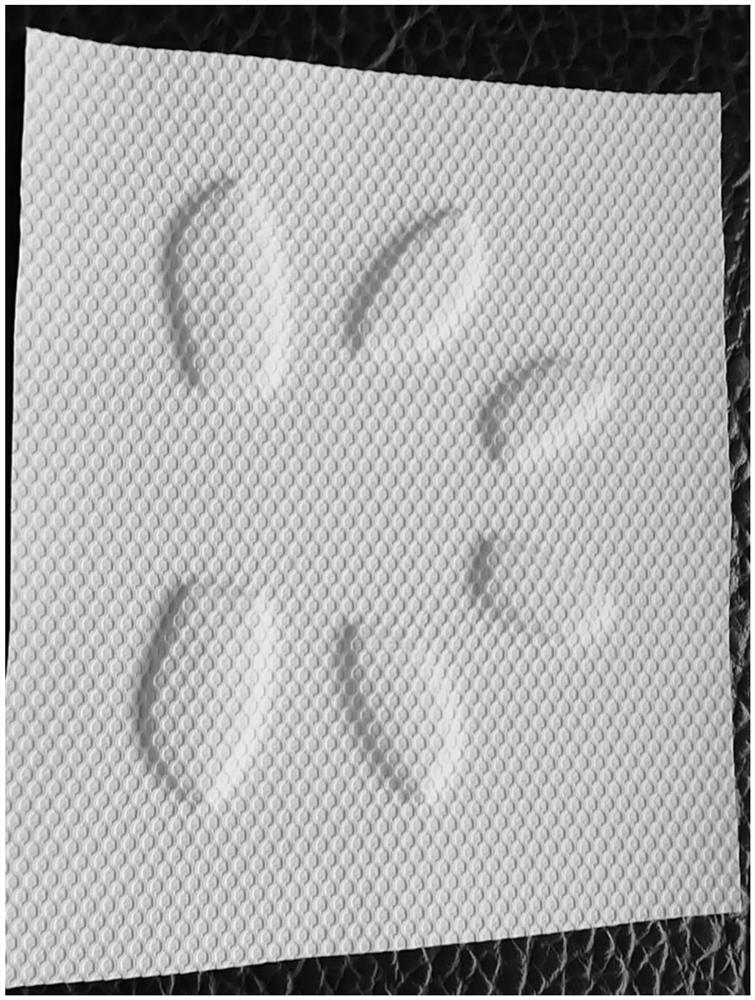

Processing method of TPU high-low temperature film composite cloth

The invention relates to the technical field of TPU high-low temperature film composite cloth processing, in particular to a processing method of TPU high-low temperature film composite cloth. The method comprises the following steps of (S1) taking a manufacturing tool, placing the manufacturing tool on a carrying table of hot pressing equipment, and then taking the TPU high-low temperature film composite cloth to be arranged on the surface of the manufacturing tool, wherein one surface, on which the TPU high-low temperature film composite cloth is placed, of the manufacturing tool is an uneven surface; (S2) laminating a soft heat-conducting layer of the hot pressing equipment on the TPU high-low temperature film composite cloth for hot pressing treatment in order to laminate the TPU high-low temperature film composite cloth and the manufacturing tool to generate deformation; and (S3) after hot pressing, integrally transferring the manufacturing tool and the TPU high-low temperature film composite cloth to a carrying table of shaping equipment for film shaping treatment, and taking out the film to obtain the three-dimensional TPU high-low temperature film composite cloth. The processing method is adopted to replace a method for manufacturing the three-dimensional TPU high-low temperature film composite cloth by adopting a mold, so that the manufacturing cost is more effectivelysaved.

Owner:DONGGUAN ZHONGDING PLASTIC PROD CO LTD

Optical thin film, mould and cover plate of electronic equipment

InactiveCN109152259AReduce thicknessReduce production processCasings/cabinets/drawers detailsOptical articlesConvex structureMicro nano

The invention discloses an optical thin film, a mould and a cover plate of an electronic equipment, wherein the optical thin film is characterized in that: A graphics structure layer located on a surface of the carrier, the graphics structure layer comprising a continuously arranged micro-nano structure, the micro-nano structure being a convex structure and / or a concave structure; Wherein the optical film visually has a stereoscopic feeling of a depth or height of not less than 1 mm. The optical film provided by the invention is provided with a graphics structure layer, and the graphics structure layer is arranged in a continuous micro-nano structure, so that stereoscopic effect can be realized by only using the one-layer structure, and visual difference of at least 1mm depth or height exists, so that the thickness of the film and the manufacturing process are reduced, and the cost is reduced well.

Owner:SHINE OPTOELECTRONICS KUNSHAN CO LTD

An audio playback method and device

ActiveCN106792365BImprove experienceTo achieve a three-dimensional effectSignal processingLoudspeaker signals distributionEngineeringComputer science

The invention discloses an audio playing method and device. The method comprises the steps of establishing communication connection with a set loudspeaker box, wherein the set loudspeaker box is equipped with at least one secondary loudspeaker; determining playing parameters of all loudspeakers according to the frequency response parameter of the at least one secondary loudspeaker and the frequency response parameter of a master loudspeaker arranged on a smart terminal, wherein the playing parameters comprise playing time and playing volume; and controlling all loudspeakers to play an audio file according to the playing parameters. According to the technical scheme provided by the embodiment of the invention, the problem that in the prior art, the smart terminal cannot play the audio file according to a three-dimensional effect through an internal loudspeaker or a single external loudspeaker is solved.

Owner:GUANGDONG XIAOTIANCAI TECH CO LTD

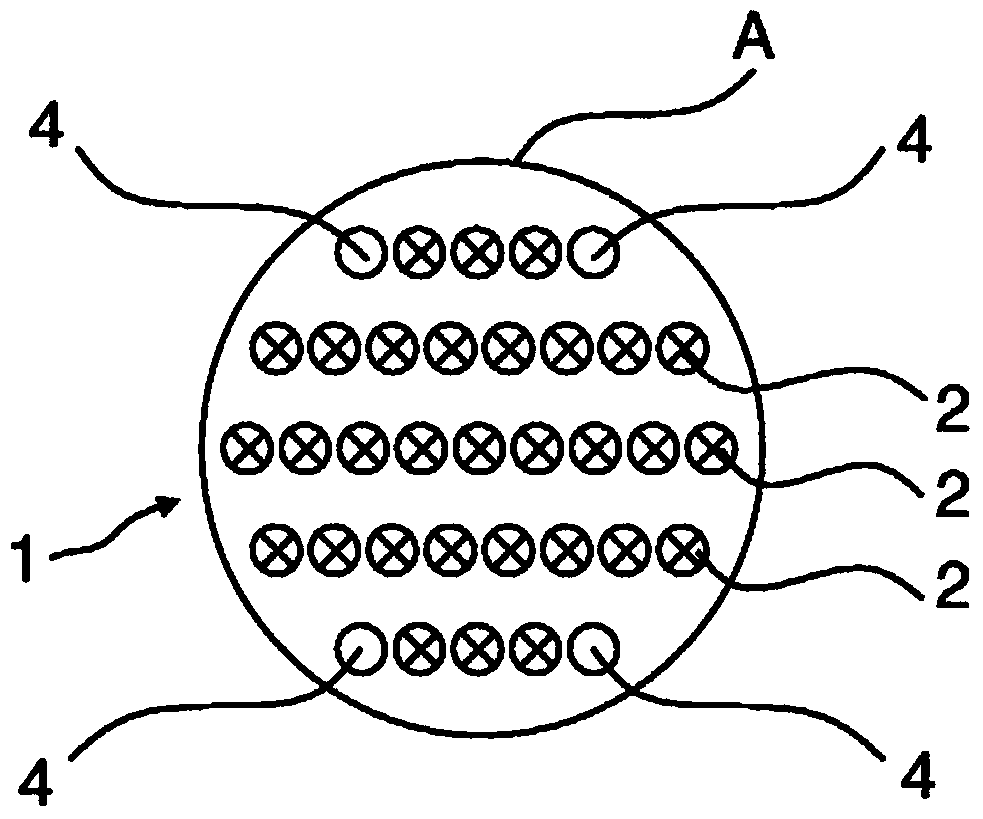

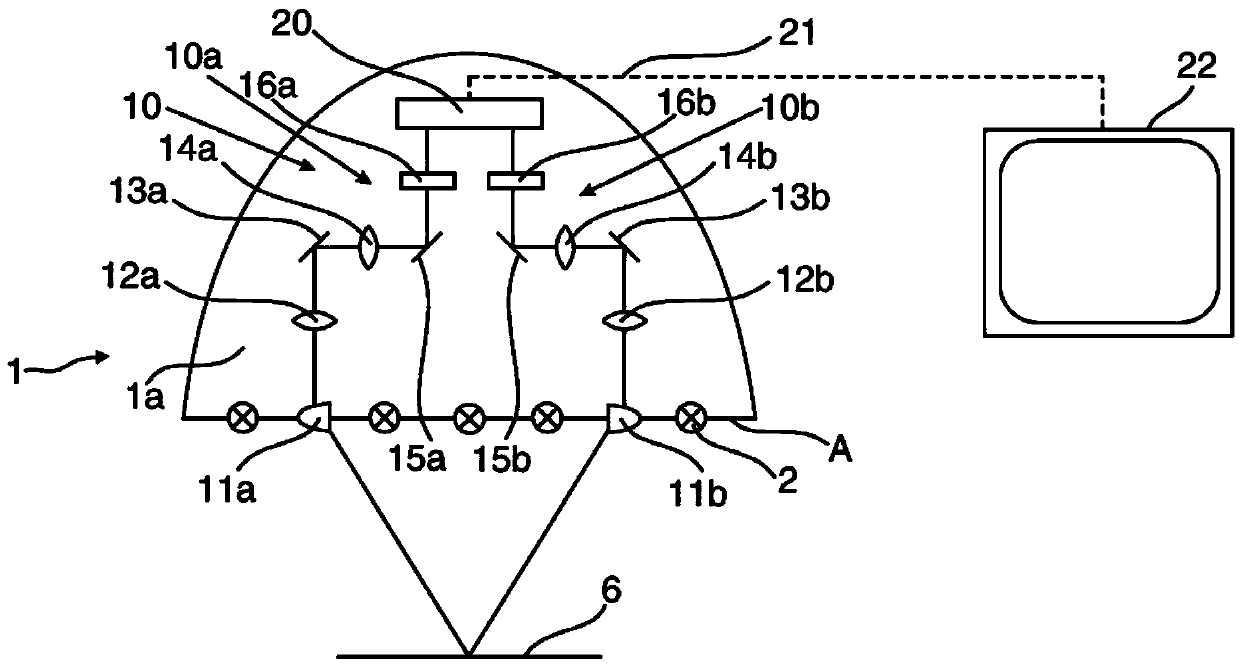

Surgical illumination device

InactiveCN103994418AConvenient lightingImprove uniformityTreatment roomsLighting elementsLight equipmentComputer science

A surgical illumination device (1) having illuminating means (2) distributed over an area (A) and a stereoscopic image acquisition device (10) having two optical channels (10a, 10b) which each generate a monoscopic image of an illuminated object (6). At least three optical channels can be present, each of which may be arranged with its object-side channel end (D1, D2, D3; C1, C2, C3, C4, C5; OL, OR, UL, UR) inside the area (A) at its periphery. Two object-side channel ends can be arranged at a same distance to at least one other channel end. If one (D2, C3, UR) of the optical channels related to the two object-side channel ends (D2, D3; C3, C4; OL, UR) is no longer supplying a monoscopic image, the other one (D3, C4; OL) of the optical channels related to said two object-side channel ends can generate a stereoscopic image.

Owner:LEICA MICROSYSTEMS (SCHWEIZ) AG

Processing method of TPU (Thermoplastic Polyurethane) high-low temperature film composite cloth

PendingCN113752527AReduce manufacturing costTo achieve a three-dimensional effectPolymer scienceThermoplastic polyurethane

The invention relates to the technical field of processing of TPU (Thermoplastic Polyurethane) high-low temperature film composite cloth, in particular to a processing method of the TPU high-low temperature film composite cloth. The method comprises the following steps: (S1) placing a manufacturing tool on a carrying table of hot pressing equipment, and then placing TPU high-low temperature film composite cloth on the surface of the manufacturing tool, wherein one surface, on which the TPU high-low temperature film composite cloth is placed, of the manufacturing tool is an uneven surface; (S2) pressing a soft heat-conducting layer of the hot-pressing equipment on the TPU high-low temperature film composite cloth for hot-pressing treatment, so that the TPU high-low temperature film composite cloth and the manufacturing tool are pressed and deformed; and (S3) after hot pressing, integrally transferring the manufacturing tool and the TPU high-low temperature film composite cloth to the carrying table of shaping equipment to carry out film shaping treatment, and taking the film so as to obtain stereoscopic TPU high-low temperature film composite cloth. The processing method is adopted to replace a method for manufacturing the stereoscopic TPU high-low temperature film composite cloth by adopting a mold, and the manufacturing cost is more effectively saved.

Owner:DONGGUAN ZHONGDING PLASTIC PROD CO LTD

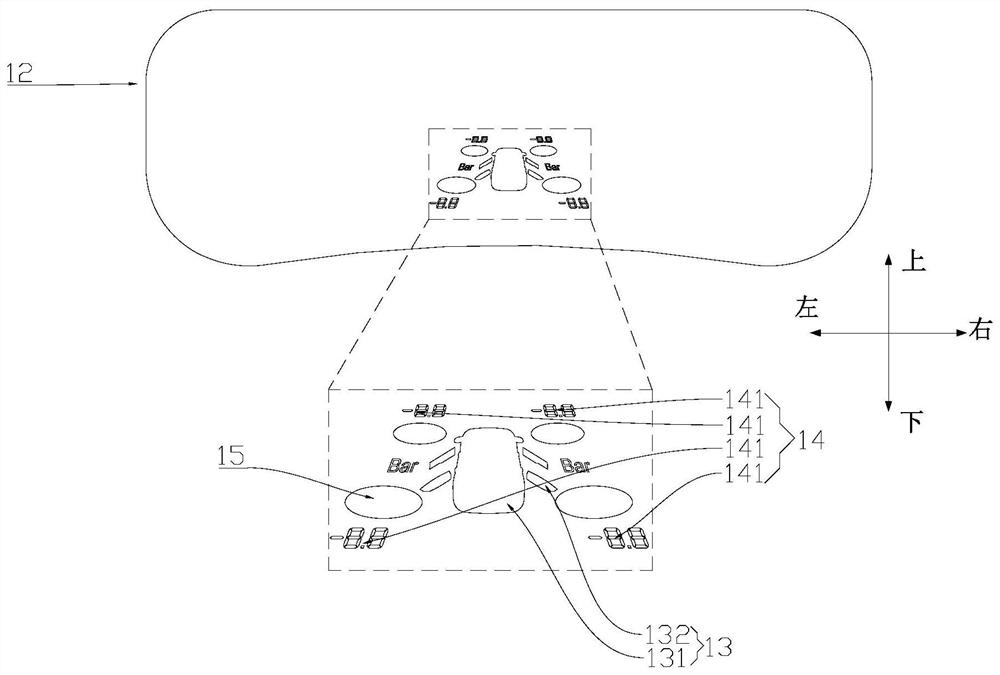

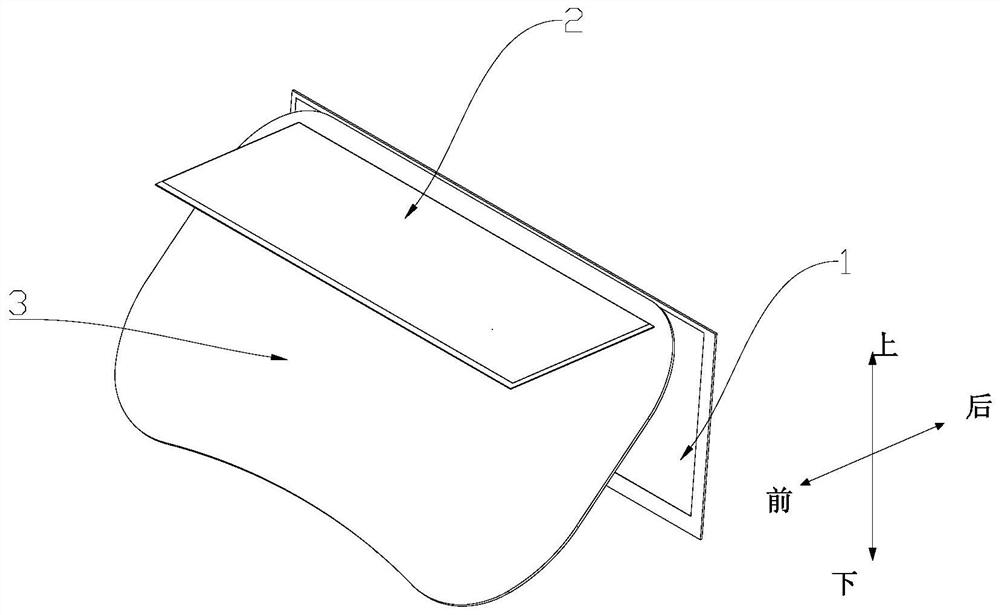

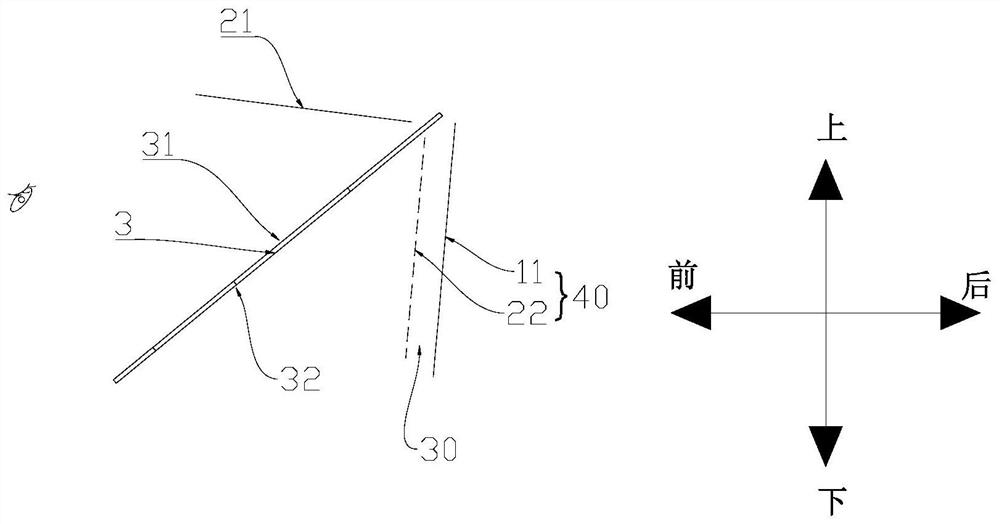

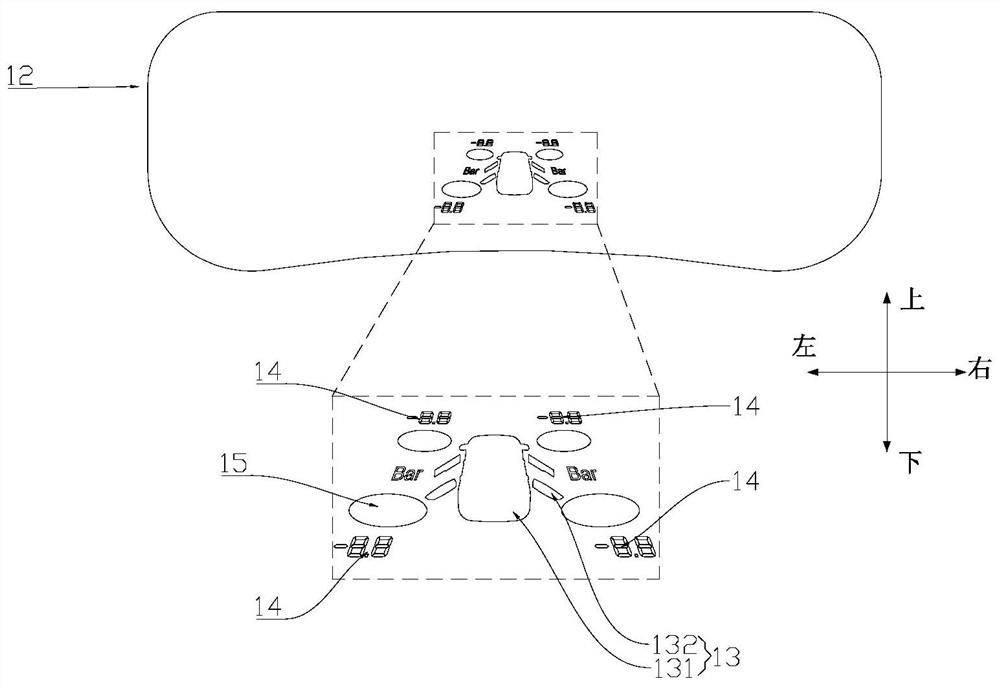

Combined automobile instrument panel

InactiveCN113895227AWith three-dimensional effectTo achieve a three-dimensional effectInstrument arrangementsDashboardMechanical engineering

The invention relates to a combined automobile instrument panel which comprises a first segment code screen, a second segment code screen and a light processing board, four main tire pressure controllable display areas are arranged in one of the first segment code liquid crystal board of the first segment code screen and the second segment code liquid crystal board of the second segment code screen, and four alarm controllable display areas are arranged in the other one of the first segment code liquid crystal board of the first segment code screen and the second segment code liquid crystal board of the second segment code screen. When the tire pressure of an individual tire is abnormal, the corresponding alarm controllable display area is lightened, so that the main tire pressure pattern displayed in the main tire pressure controllable display area corresponding to the tire with the abnormal tire pressure is located in the alarm pattern, the driver obtains the tire with the abnormal specific tire pressure, and the driver is effectively reminded to maintain the tire pressure in a normal state.

Owner:HEILONGJIANG TIANYOUWEI ELECTRONICS CO LTD

A naked-eye 3D display device suitable for LED screens

The invention provides a naked-eye 3D display device for an LED screen. The naked-eye 3D display device comprises a display device and a supporting device. The display device includes an ED display screen, a lenticular grating and a controller. The LED display screen and the controller are electrically. The supporting device includes a main body bracket and a device box; the device box having an Lshape is installed at the main body bracket; and a first displacement mechanism and a second displacement mechanism that are connected with the controller electrically are arranged in the device box.The LED display screen and the lenticular grating are fixedly installed in the device box; the lenticular grating is arranged right in front of the LED display screen; the LED display screen can moveback and forth or rotate horizontally in the device box by the first displacement mechanism; and the lenticular grating can move up and down in the device box by the second displacement mechanism. According to the invention, problems of single structure and poor functionality of the existing naked-eye 3D display device can be solved. Free switching between 3D displaying and 2D displaying is realized; and thus the user can watch a 3D picture or a 2D picture.

Owner:HANGZHOU XINGKAI MEDICAL IMAGING TECH CO LTD

Three-dimensional flower glaze for feldspar porcelain decoration and application method thereof

The invention relates to a three-dimensional flower glaze for feldspar porcelain decoration and an application method thereof. The weight percentage of the bottom glaze is composed of: 10-15% of albite, 15-20% of hectorite, and 10-10% of bottle glass powder. 15%, titanium dioxide 5-10%, white clay 25-30%, zinc oxide 2-5%, strontium carbonate 5-10%, spodumene 5-10%, colored oxide 2-5%; the surface glaze The weight percent composition of: potassium feldspar 10-15%, lithium feldspar 20-25%, bottle glass powder 5-10%, titanium dioxide 2-5%, white clay 20-25%, Suzhou soil 10-15%, Zinc oxide 5-10%, spodumene 10-15%, coloring oxide 2-5%, through batching, ball milling, sieving, iron removal, glazing and firing twice at low temperature and high temperature to obtain a flower with a strong three-dimensional effect Glaze decorative effect. The invention has the advantages of simple process, low cost, distinct layers and stable performance, so it has wide application prospects.

Owner:JINGDEZHEN CERAMIC UNIV

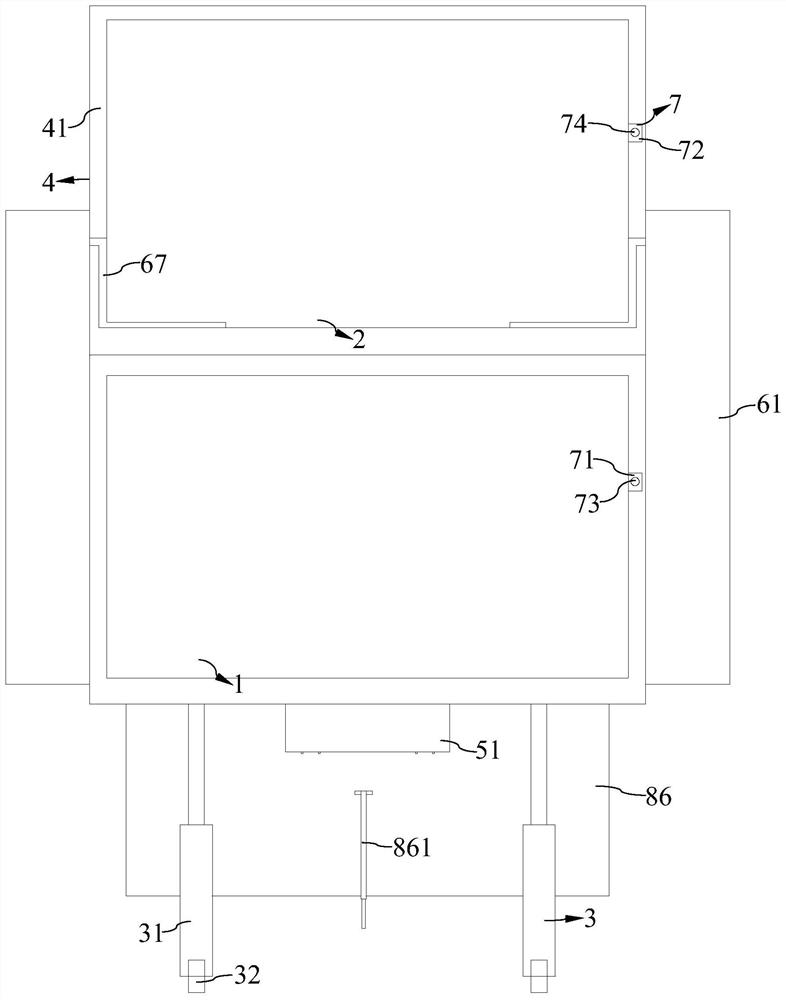

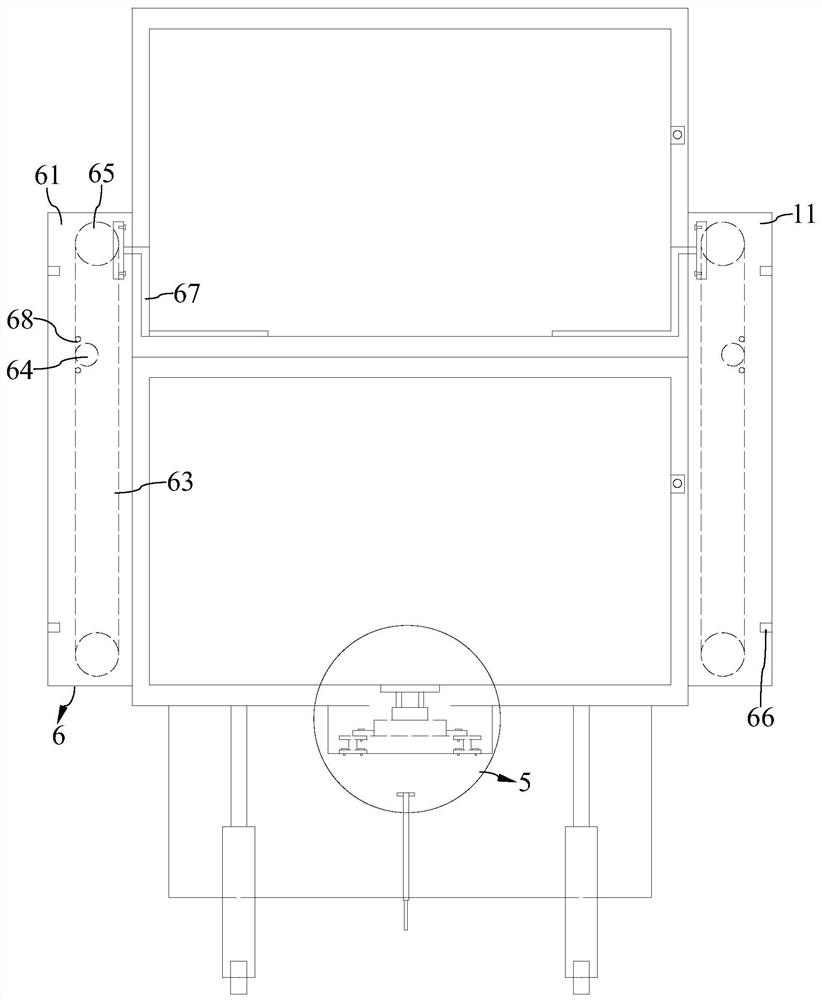

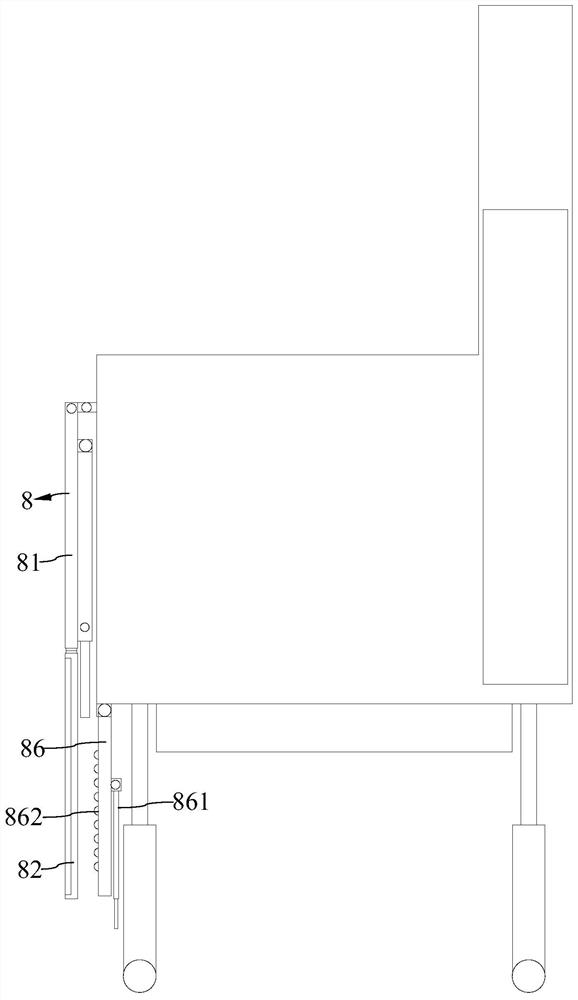

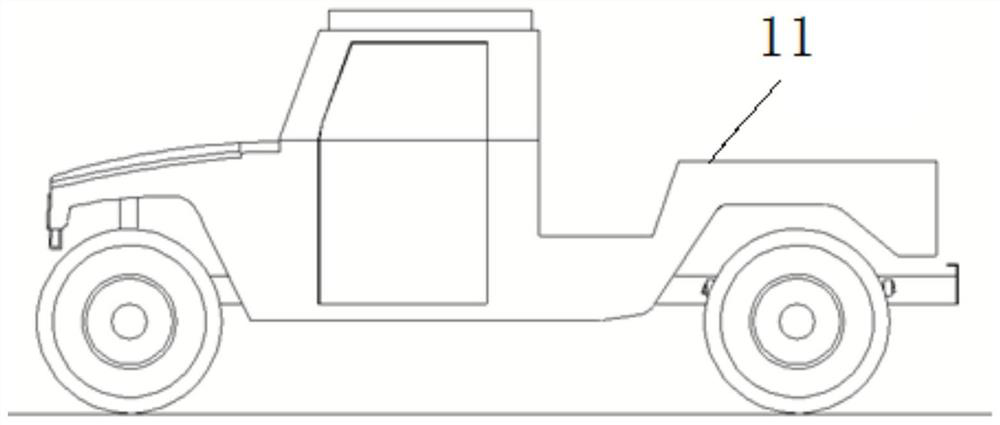

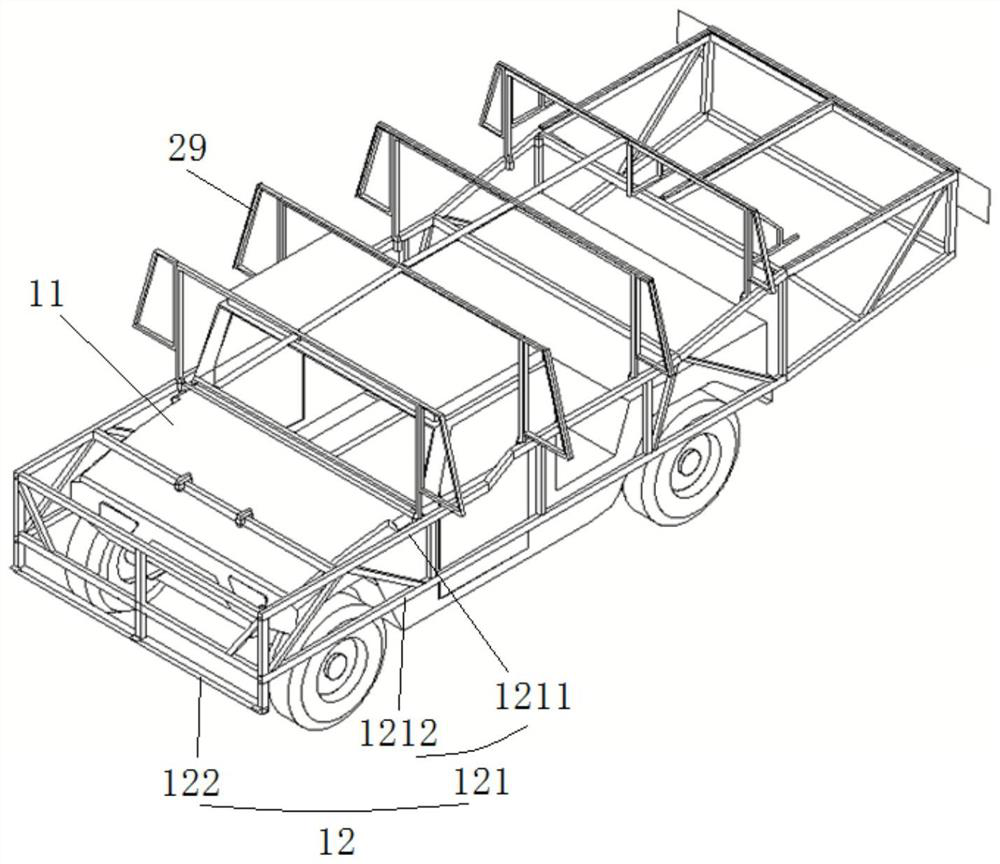

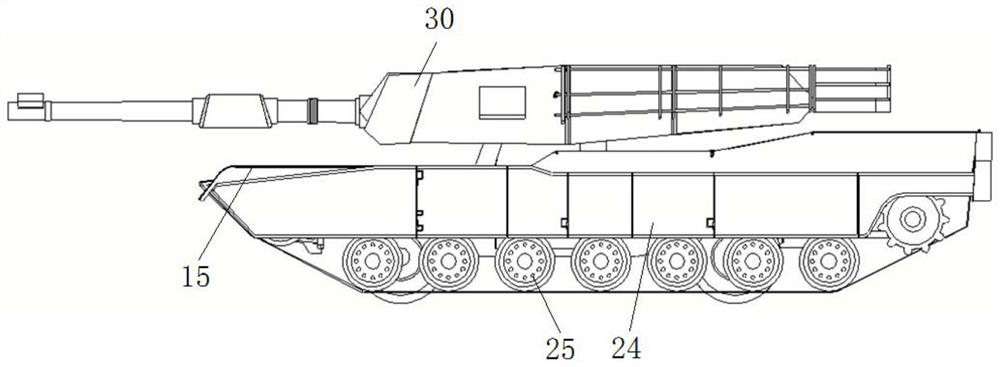

Unmanned profiling target vehicle

PendingCN114413688AEasy to disassembleSave manufacturing costMovable targetsStructural engineeringMechanical engineering

The invention discloses an unmanned profiling target vehicle which comprises a target vehicle body configured to be capable of moving in an unmanned mode. The target vehicle body is sleeved with the main frame, the main frame is fixedly connected with the target vehicle body, and the front portion, the rear portion, the left portion and the right portion of the target vehicle body are all located within the range of the main frame; the connecting assembly is detachably connected with the main frame, and the length of the connecting assembly extends in the direction away from the main frame; the first profiling assembly is fixedly connected with the connecting assembly; the first profiling assembly is connected to the main frame through the connecting assembly. The left side and the right side of the main frame can be widened through connection of the connecting assemblies and the main frame, and the three-dimensional effect of profiling is achieved after assembly. Due to detachable connection, the connecting assembly and the first profiling assembly can be detached from the main frame, and production, storage and transportation are facilitated; the main frame is light in weight, the profiling assembly can be quickly disassembled and assembled, and the whole high-simulation-degree profiling target vehicle is good in passing ability.

Owner:航天科工智能机器人有限责任公司

A Realization Method of Stereo Ball Screen Projection System

ActiveCN104977796BOptimize seating arrangementInstallation Angle RestrictionsStereoscopic photographyPanoramic photographyProjection systemWorkload

The invention relates to a realization method of a stereoscopic spherical-screen projection system. The method comprises the following steps: 1) arranging a plurality of projection channels at the edge of a spherical screen body, wherein each projection channel is provided with two projectors; 2) generating a mesh model with a computer based on spherical screen curved surface, carrying out fan-shaped segmentation on the mesh model according to the number and position of the projection channels, and selecting an effective fan-shaped area for each projection channel; 3) carrying out curved surface correction and edge fusion on each fan-shaped area; 4) adjusting the positions of the projectors and combining computer fusion fine tuning, and realizing left and right eye splicing of the projection channels to enable the projection picture of each projection channel to cover the spherical screen curved surface completely; and 5) carrying out synchronous output and synchronous projection on multichannel pictures. The realization method of the stereoscopic spherical-screen projection system is small in projection picture and small in picture pixel loss, and ensures definition and brightness of the pictures; and meanwhile, by enabling the adjacent cutting regions to form a regular fusion band, workload of the later-period correction work is greatly reduced.

Owner:SHANGHAI HUABO INFORMATION SERVICE

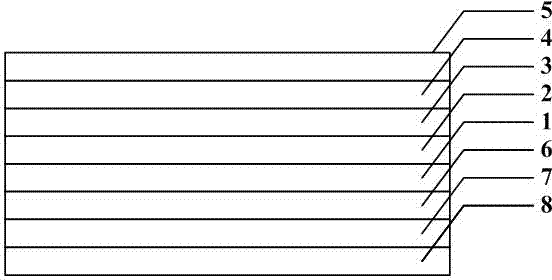

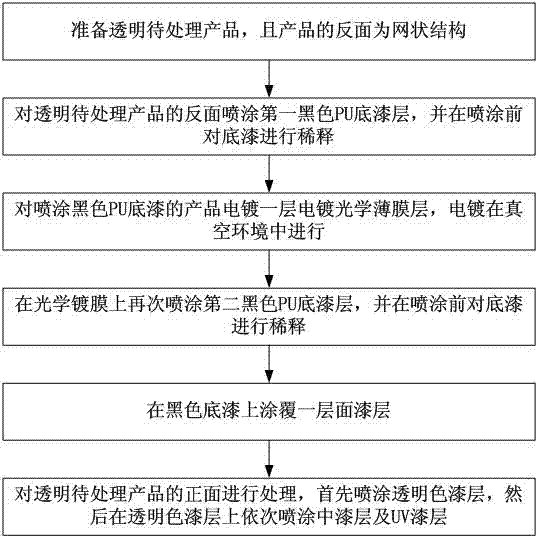

A kind of optical film and preparation method thereof

ActiveCN102615880BRich preparation methodTo achieve a three-dimensional effectSpecial surfacesCoatingsConductive coatingThin membrane

The invention discloses an optical film. A transparent product to be processed is used as a substrate of the optical film, the reverse side of the transparent product to be processed is of a net structure; the optical film is a two-layer film with a front side and a reverse side; the reverse side film sequentially comprises a first black PU (Polyurethane) primer layer, an electroplating optical film layer, a second black PU primer layer and a finish layer from the transparent product to be processed to the outside; and the front side film sequentially comprises a transparent color paint layer, a middle paint layer and a UV (Uultraviolet) finish layer from the transparent product to be processed to the outside. Through spraying, electroplating and baking preparation, the three-dimensional effect of the optical film appearance is realized, the preparation method of non-conductive coating plastic surfaces is enriched, diverse colors of the optical film appearance can be realized at the same time to achieve the process effect that cannot be realized by the front color of the former material, and the optical film has very strong third dimension.

Owner:宜宾市创世纪机械有限公司

Stereo vision inspection method and device using symmetrical adjustable backlight structure

ActiveCN105049833BImprove uniformityIncrease brightnessSteroscopic systemsOptical elementsBeam splitterLight guide

A stereoscopic inspection device adopting a symmetrical adjustable backlight structure, including a symmetrical adjustable backlight device, a pupil position tracking module, a synchronous signal extraction module, a signal processing module, and an image display screen; the symmetrical adjustable backlight device includes a symmetrical adjustable optical component , addressable light source assembly; wherein, the symmetrically adjustable optical assembly includes a light guide module and a symmetrically adjustable imaging module, the light guide module includes: a condenser lens, a light guide device and a triangular prism, and the symmetrically adjustable imaging module ( M) includes: a lens, a lens switching device, a refracting mirror, a beam splitter and a refracting mirror; the signal processing module controls the addressable light source components in the adjustable backlight structure according to the received pupil position information and video synchronization signal. While displaying the left image, the signal processing module lights up the corresponding light-emitting unit according to the position information of the pupil of the left eye to realize the convergence of light at the pupil of the left eye; while displaying the right image, the signal processing module The corresponding light-emitting unit lights up to realize the convergence of light at the pupil of the right eye.

Owner:NANJING UNIV

Electronically controlled stereoscopic 3D grating film

The invention relates to an electronically controlled stereoscopic 3D grating film, comprising: a base film and conductive parts, wherein a plurality of conductive parts are arranged in the base film, the plurality of conductive parts are distributed in parallel along the length direction of the base film, the two ends of the conductive parts are respectively connected with positive electrode wire rows and negative electrode wire rows; when the two ends of the conductive parts are connected to a power source, the voltage between the positive electrode wire rows and the negative electrode wirerows can be adjusted, the refractive index of each point of the base film is changed by adjusting the voltage of the conductive parts, and there is a parallax between left images and right images ofdifferent viewpoints observed by left and right eyes.

Owner:SUZHOU UNIV OF SCI & TECH

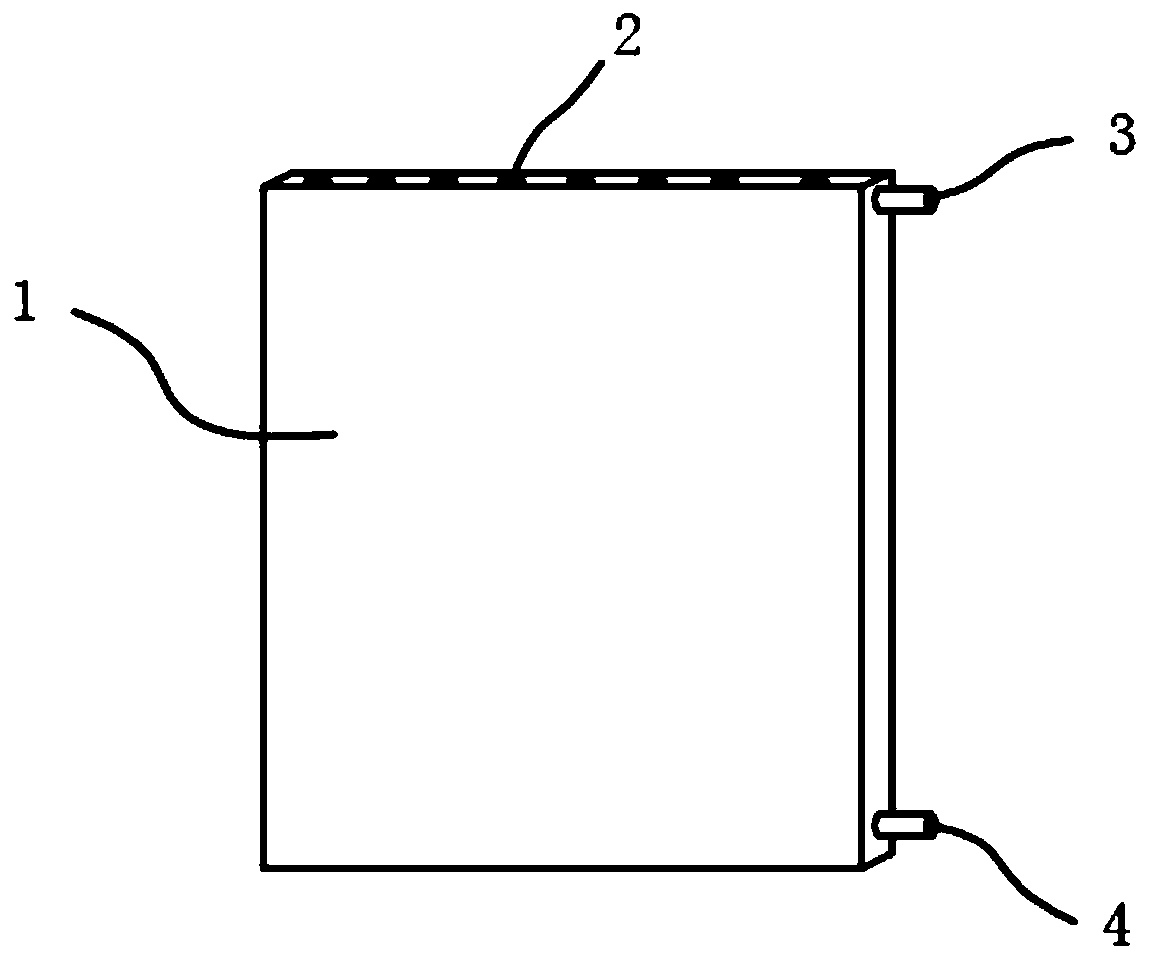

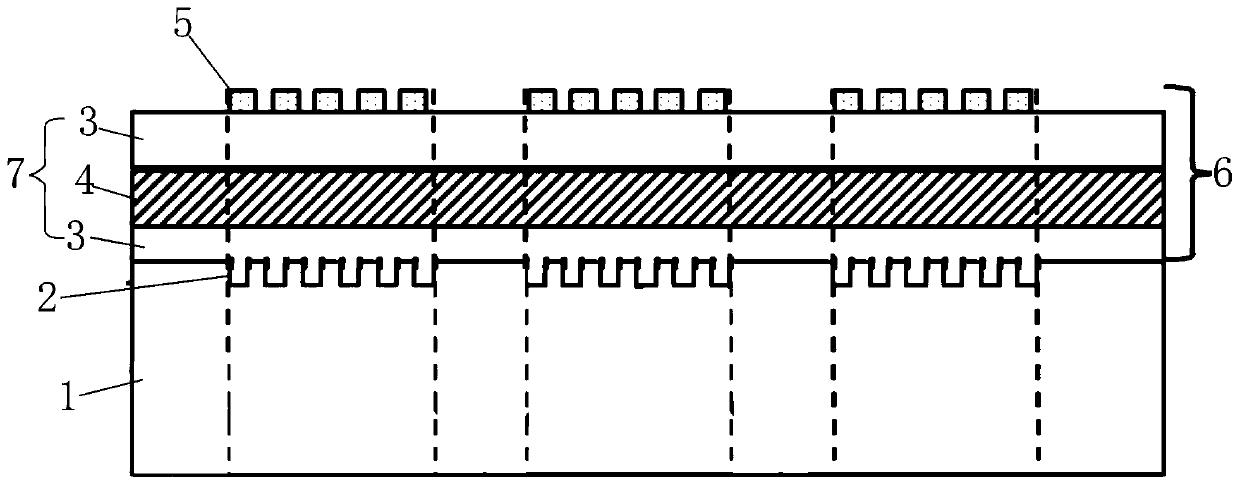

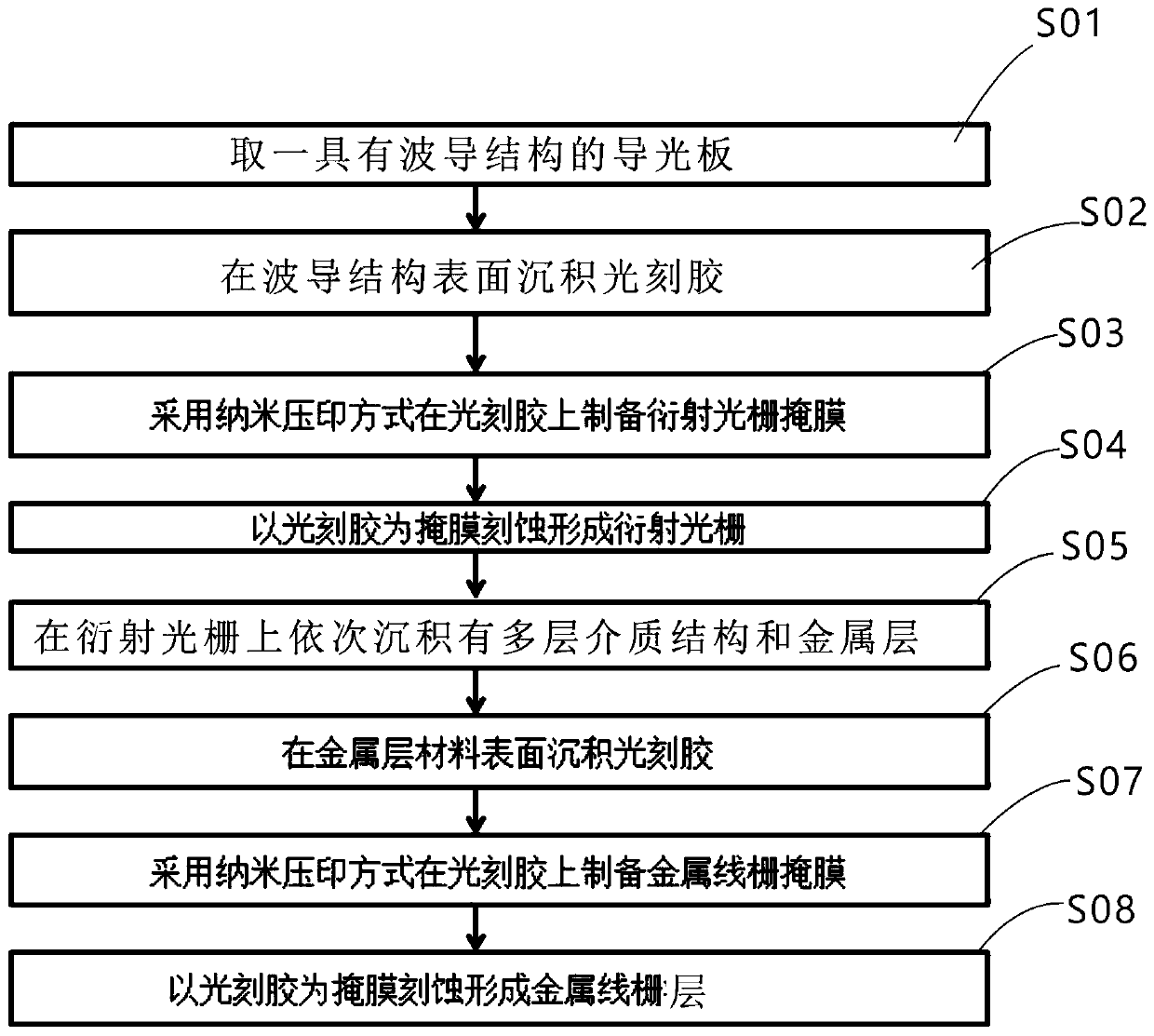

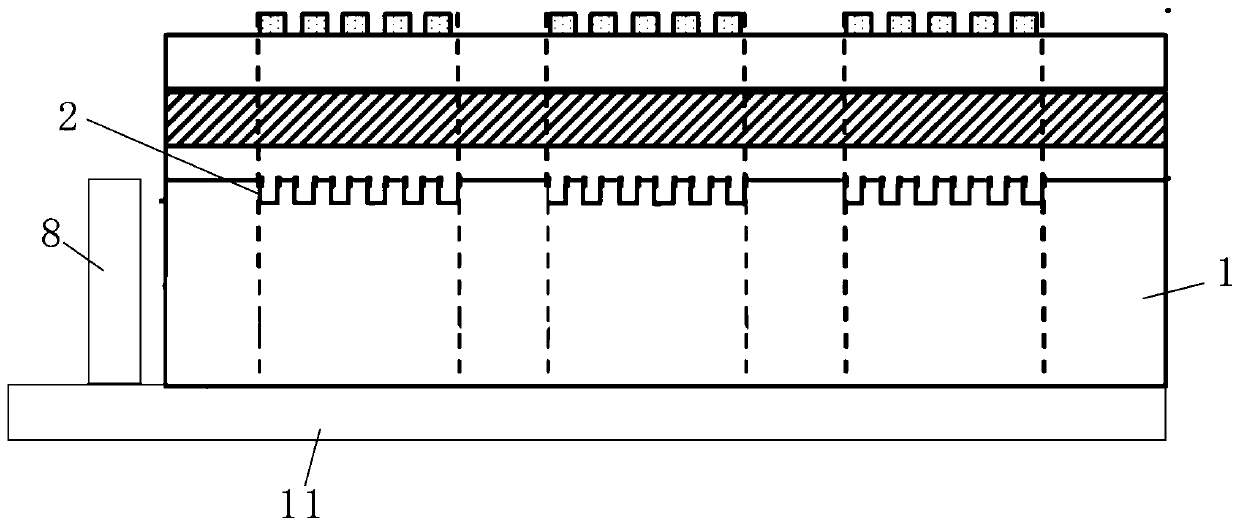

A light guide plate and its manufacturing method, a backlight module, and a liquid crystal display module

ActiveCN106526738BNarrow passband rangeRealize naked eye stereoscopic effectPlanar/plate-like light guidesNon-linear opticsLiquid-crystal displayLight guide

The invention provides a light guide plate. The light guide plate comprises a light guide plate body, wherein a wave-guiding structure is arranged on the surface of the light guide plate body, a diffraction grating is formed on the wave-guiding structure, a metal wire gating light filter structure is arranged on the diffraction grating and comprises a multilayer medium structure for modulating the refractive index, a metal wire gating layer is arranged on the multilayer medium structure, and grid lines of the metal wire gating layer are in one-to-one correspondence with grid lines of the diffraction grating. A production method of the light guide plate comprises the steps of preparing a diffraction grating mask, the multilayer medium structure and the metal wire gating layer on the light guide plate body with the wave-guiding structure. The invention further provides a backlight module and a liquid crystal display module. Compared with the prior art, the diffraction grating and the metal wire gating layer are mutually matched, so that a high-color-purity, low-dispersion and multi-view three-dimensional display effect can be achieved, and the problems that the color degrees of rays projected into a space are not uniformly scattered and the colors are crossed are solved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com