A light guide plate and its manufacturing method, a backlight module, and a liquid crystal display module

A technology of backlight module and light guide plate, applied in the direction of light guide, optics, optical components, etc., can solve the problems of uneven light chromaticity dispersion, color crosstalk, etc., achieve high color purity, save process equipment, and avoid color crosstalk effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

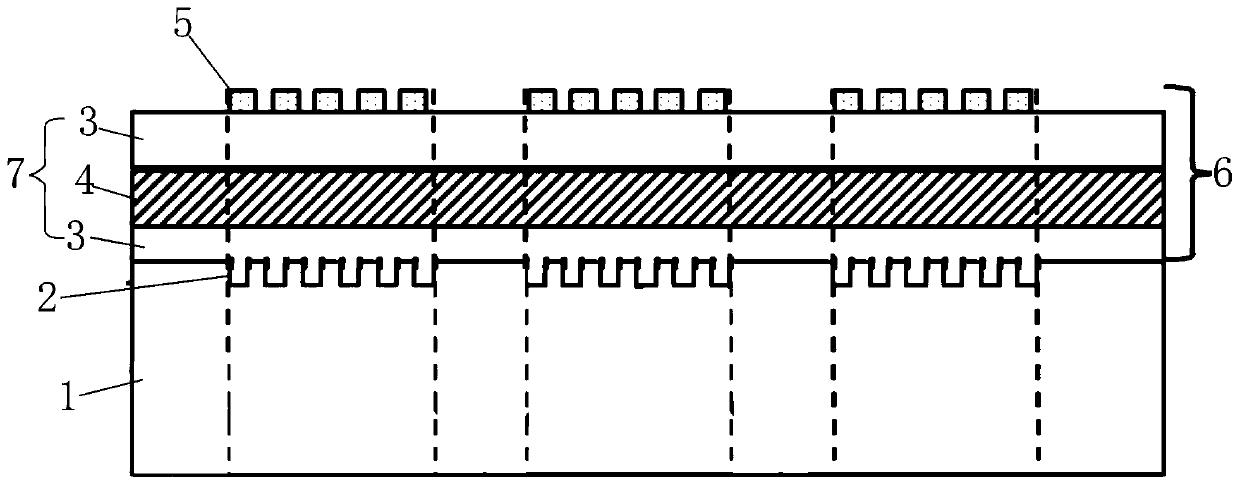

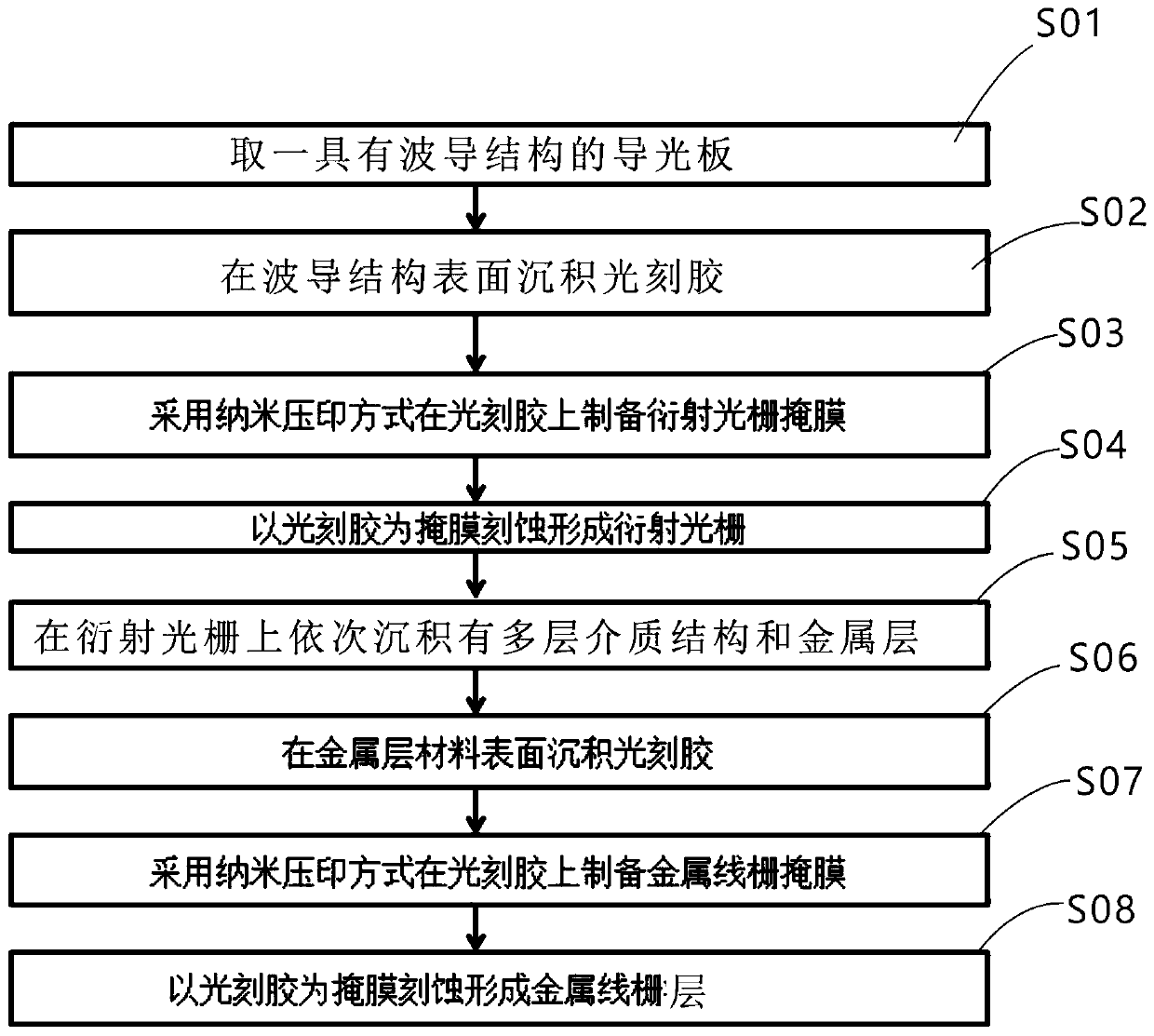

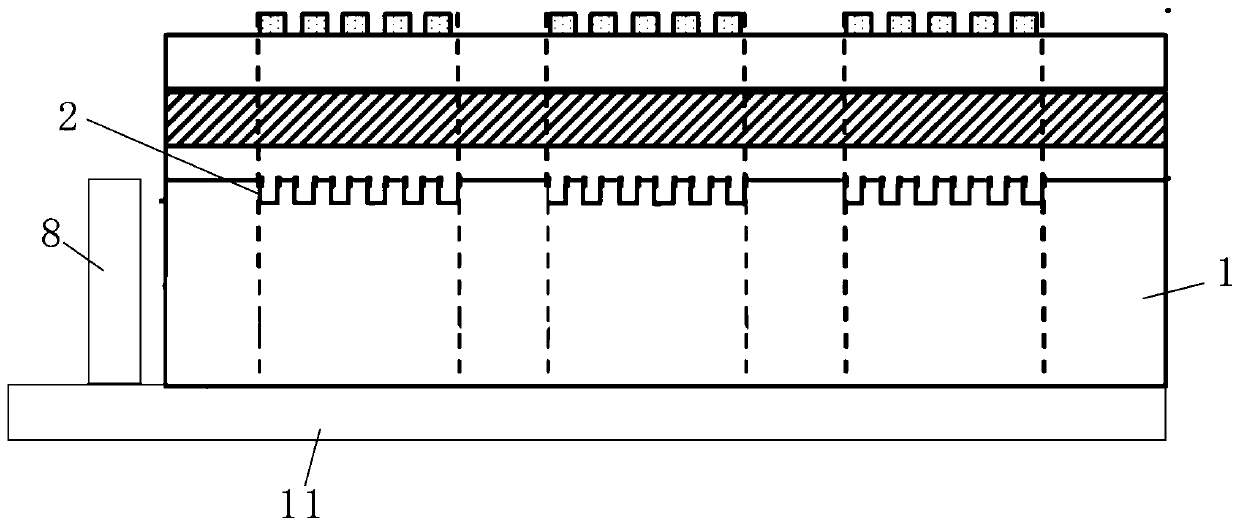

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0030] like Image 6 As shown, it is a schematic diagram of the basic principle of the diffraction grating light guide plate. When a beam of collimated monochromatic light passes through a diffraction grating whose period parameter is close to the wavelength of visible light, the light rays passing through different opening positions of the grating converge to different positions in space, due to Different optical paths have different phase differences, so only when the phase difference in a specific direction satisfies integer multiples of the wavelength will there be directional projection of light intensity. Set the polar coordinates of the incident light direction as The polar coordinates of the outgoing light are By setting the duty cycle of the diffraction grating to 0.5, when the material of the light guide plate takes a larger refr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com