Ultra-thin EVA vacuum casting film

A vacuum casting, ultra-thin technology, used in layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problem of inability to achieve thin film thickness, achieve excellent thermal elongation and thermal strength properties, contain Low carbon content, avoidance of porosity problems and effect of carbon increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

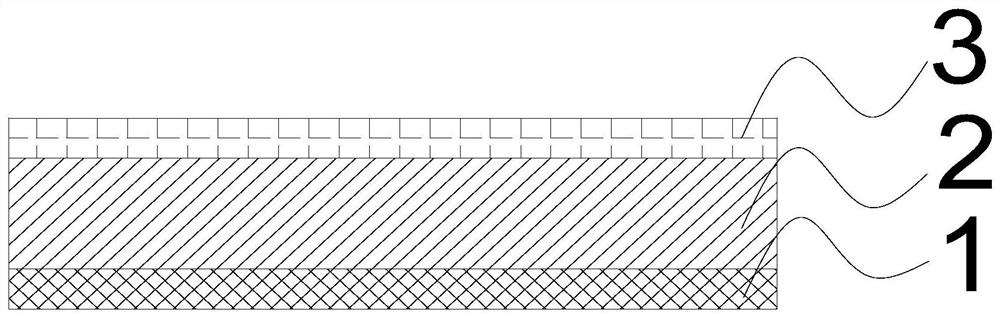

[0048] Such as figure 1 As shown, the embodiment of the invention provides a kind of ultra-thin EVA vacuum casting film, comprising:

[0049] Inner layer 1: thickness 6μm, 39kg raw material A, 9kg raw material C, 1kg anti-adhesive masterbatch A, 1kg anti-adhesive masterbatch B.

[0050] Middle layer 2: Thickness ratio 48μm, 192kg raw material C, 48kg raw material D.

[0051] Outer layer 3: Thickness ratio 6μm, 39kg of raw material A, 9kg of raw material B, 1kg of anti-adhesive masterbatch A, 1kg of anti-adhesive masterbatch B.

Embodiment 2

[0053] Such as figure 1 As shown, the embodiment of the invention provides a kind of ultra-thin EVA vacuum casting film, comprising:

[0054] Inner layer 1: thickness 6μm, 39kg raw material A, 9kg raw material C, 1kg anti-adhesive masterbatch A, 1kg anti-adhesive masterbatch B.

[0055] Middle layer 2: Thickness ratio 42μm, 168kg raw material C, 72kg raw material D.

[0056] Outer layer 3: thickness ratio 12μm, 48kg of raw material A, 48kg of raw material B, 2kg of anti-adhesive masterbatch A, 2kg of anti-adhesive masterbatch B.

Embodiment 3

[0058] Such as figure 1 As shown, the embodiment of the invention provides a kind of ultra-thin EVA vacuum casting film, comprising:

[0059] Inner layer 1: thickness 12μm, 48kg raw material A, 48kg raw material C, 2kg anti-adhesive masterbatch A, 2kg anti-adhesive masterbatch B.

[0060] Middle layer 2: Thickness ratio 36μm, 108kg raw material C, 72kg raw material D.

[0061] Outer layer 3: thickness ratio 12μm, 48kg of raw material A, 48kg of raw material B, 2kg of anti-adhesive masterbatch A, 2kg of anti-adhesive masterbatch B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com