Integrated mounting bracket and vehicle

A mounting bracket, integrated technology, applied in vehicle components, transportation and packaging, heating/cooling equipment, etc., can solve the problems of difficult layout and insufficient layout space in the engine room, and achieve the effect of solving insufficient layout space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

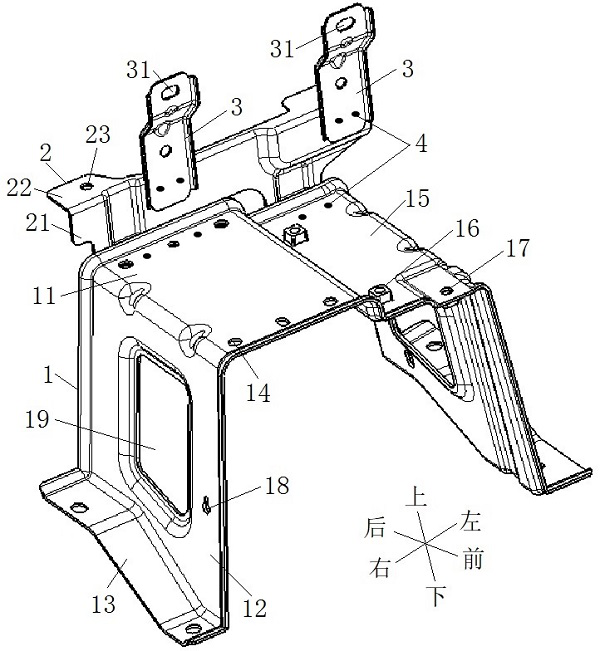

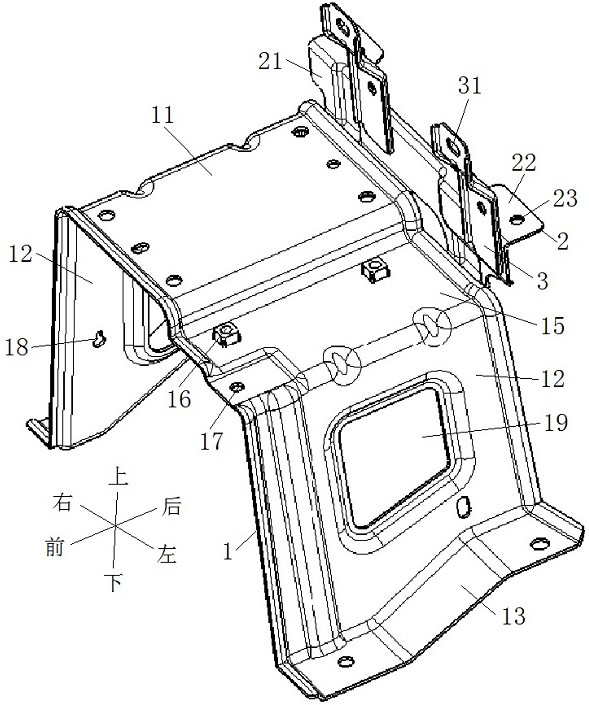

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

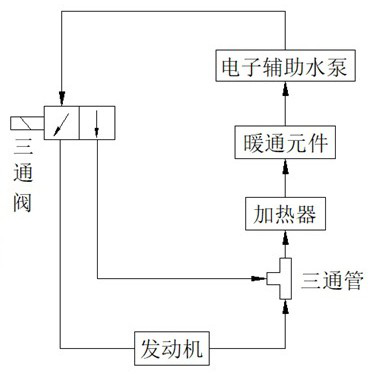

[0022] see Figure 2 to Figure 5 , the shown integrated mounting bracket includes a first bracket 1 and a second bracket 2. The first bracket 1 is in the shape of a few characters in longitudinal section, and includes a top plate 11 and side plates 12 connected to the left and right sides of the top plate. The lower end of the plate 12 is bent to form a fixing portion 13 , and the front and rear ends of the left half of the top plate 11 are respectively provided with three first installation holes 14 for fixing the heater 5 , which is located above the top plate 11 . The right half of the top plate 11 sinks to form a step installation part 15, and the step installation part 15 is provided with two second installation holes 16, and a projection welding nut is fixed on the upper end of the second installation hole 16 for fixing the tee Valve 6, the three-way valve 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com